Re: [Testers Needed] Inconsistent Extrusion

Regarding over extrusion, I tested this a few pages back. I saw no difference in the inconsistency all the way down to 65% percent flow rate I believe, and shortly after that (60%) I started having wall gaps due to not enough filament being extruded to keep a solid line.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

It's possible to synchronize some of the artefacts to the width of the cube by printing a slightly slanted version of the cube:

l=20.68;

f1=1.005;

linear_extrude(height=20,scale=f1) square(l);

echo(l=l,l2=l*f1);

The exact numbers may not apply, just to give an idea.

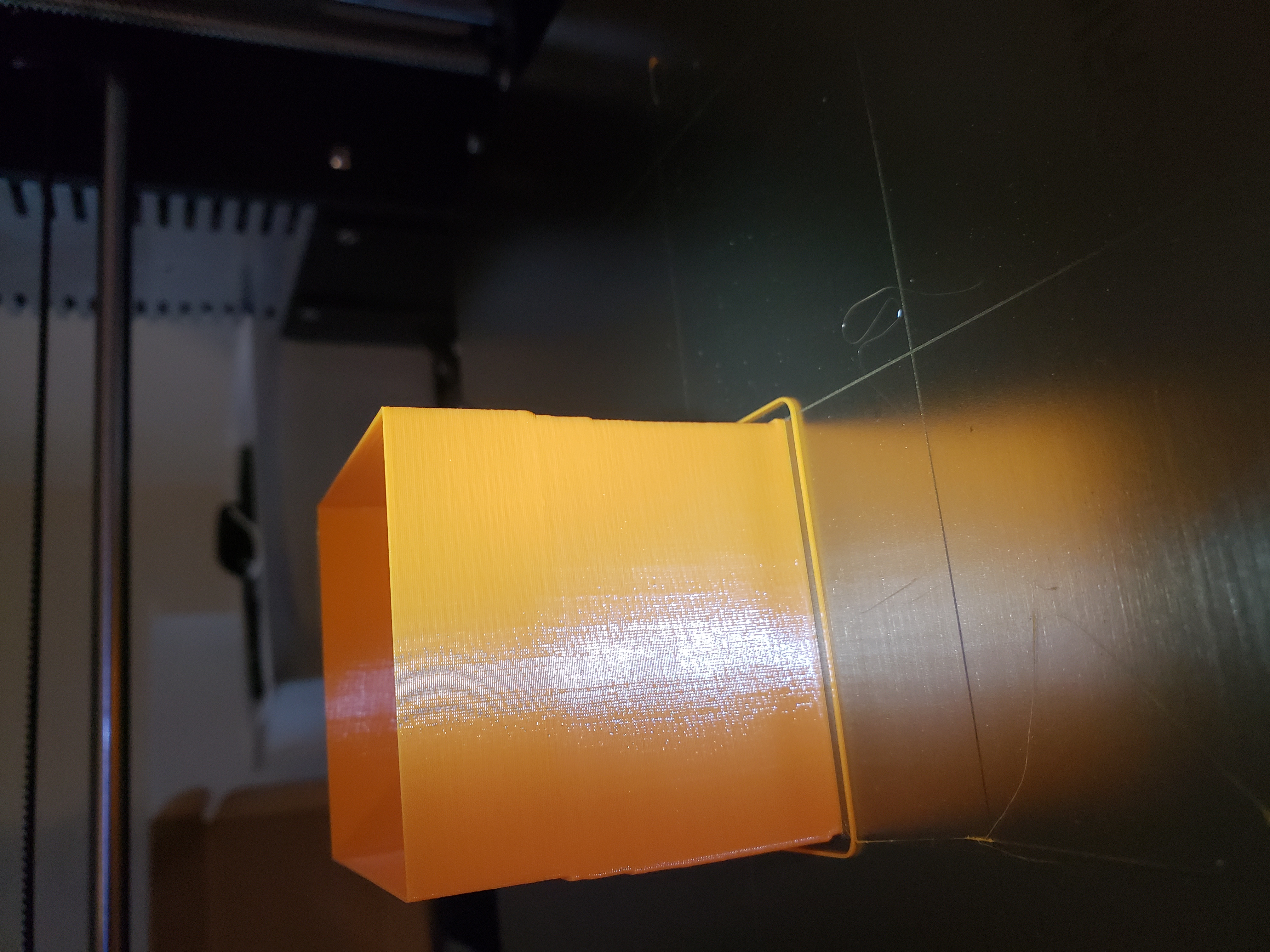

I get the effect like this:

IMG_20180409_083300.jpg

I'll try with a 2x or 3x scaled version to see if it's vibration of the print head as it will die off in this case.

That tree-ring is stepper/driver related. it could even be related to axis skew compensation.... if enabled.

Re: [Testers Needed] Inconsistent Extrusion

I see someone commented on GIT about the heat bad. Has anyone tried a print not using it?

I’m now going zzz or I’d give it a go.

Something I haven’t checked either is if my power supply is actually out putting 24v also.

Re: [Testers Needed] Inconsistent Extrusion

It got me thinking. There is not much metall or else on the Prusa but its still possible that moving the magnets or the nozzle around is by itself enough to cause vibrations due to different magnetic forces depending on what moves where.

To be honest i would be surprised if that was strong enough to cause those inconsistencies. Just wanted to throw that in there.

I could print a cube with the heatbed off later tonight but its not as bad for me as some of the others here so not sure if mine would be telling much.

Cheers

Oliver

Re: [Testers Needed] Inconsistent Extrusion

It got me thinking. There is not much metall or else on the Prusa but its still possible that moving the magnets or the nozzle around is by itself enough to cause vibrations due to different magnetic forces depending on what moves where.

To be honest i would be surprised if that was strong enough to cause those inconsistencies. Just wanted to throw that in there.

I could print a cube with the heatbed off later tonight but its not as bad for me as some of the others here so not sure if mine would be telling much.

Cheers

Oliver

The neodymium magnets in the heatbed are quite strong they pull with a deathgrip everything that gets close withing 1-2cm of their magnetic field.

But the frame, the PSU and the threaded rod are non-magnetic, only the smooth rods and the motor casings are.

Could be that it causes some magnetic interference and cause some very minor jerkiness, but they should be strongest when the bed is in the middle of the frame, or in the back.

Perhaps print a test cube at the frontmost part of the bed, and one in the center, to see if the tree ring issues are still there?

Re: [Testers Needed] Inconsistent Extrusion

If the Extruder stepper is losing steps would there be any mileage in trying a bigger steppers, I know mine runs very hot at times with minimal pressure on the bontech gears, its clearly on the edge on what it can take current wise.

Am I right in thinking its an 1A 1.8 degree nema 17, Is there anything special about it? I have some 1.4A laying around I've used before

Re: [Testers Needed] Inconsistent Extrusion

...

I noticed something during my second print yesterday.

My Z couplers are moving from side to side even on straight lines. That means the Z axis is slightly moving up and down midprint. (My leadscrews are docked against the motor shaft in the Z couplers to minimize the effect of Z-Hop)

You probably cannot see this on your machines, since you are using integrated leadscrews, it's much harder to see there.

(The ones on the Z axis that connect the stock motor shafts with the standard threaded rods, Prusa only used these integrated without couplers)

Perhaps sticking a long piece of Tape on your leadscrews shows this effect.

The way they move from side to side when printing straight lines weirded me out at first, but i think these need to do that to compensate for a slight skew in the bed parallel to the X and Y axis.

But, they seem to move a bit more than my 0.07° skew that's displayed in the menu. Or why are they moving for print moves in the Z height above the first layer at all?

The fact that the Z axis are moving up and down mid print could very well explain the layer lines.

Z axis moves slightly up = thinner looking layer

Z axis moves slightly down = layer gets squished

This is not just for the first layer, it's for every layer.

Perhaps this is cause of a problem?

Overcompensating for skew correction?

Wouldn't it make more sense to correct a Z angle skew on the first layer, and leave all other following layers without this skew correction?

That way the layers on top of the first one are as consistent as they can be, leaving only skew correction from the X and Y axis.

I don't know where to post this, so i'll post this here and in scratch built MK3 topic.

3x pictures of the XYZ skew correction included, and one very large and very LOUD video, hosting is on MEGA

(my camera makes slight noises very loud, sorry)

https://mega.nz/#!DXwC2RKA!QiCqc8XvafRg6bR5RdyQLK7JkmvDpHI-qK4FcgXfTpk

Re: [Testers Needed] Inconsistent Extrusion

...

I noticed something during my second print yesterday.

My Z couplers are moving from side to side even on straight lines. That means the Z axis is slightly moving up and down midprint. (My leadscrews are docked against the motor shaft in the Z couplers to minimize the effect of Z-Hop)

You probably cannot see this on your machines, since you are using integrated leadscrews, it's much harder to see there.

(The ones on the Z axis that connect the stock motor shafts with the standard threaded rods, Prusa only used these integrated without couplers)

Perhaps sticking a long piece of Tape on your leadscrews shows this effect.

The way they move from side to side when printing straight lines weirded me out at first, but i think these need to do that to compensate for a slight skew in the bed parallel to the X and Y axis.

But, they seem to move a bit more than my 0.07° skew that's displayed in the menu. Or why are they moving for print moves in the Z height above the first layer at all?

The fact that the Z axis are moving up and down mid print could very well explain the layer lines.

Z axis moves slightly up = thinner looking layer

Z axis moves slightly down = layer gets squished

This is not just for the first layer, it's for every layer.

Perhaps this is cause of a problem?

Overcompensating for skew correction?

Wouldn't it make more sense to correct a Z angle skew on the first layer, and leave all other following layers without this skew correction?

That way the layers on top of the first one are as consistent as they can be, leaving only skew correction from the X and Y axis.

I don't know where to post this, so i'll post this here and in scratch built MK3 topic.

3x pictures of the XYZ skew correction included, and one very large and very LOUD video, hosting is on MEGA

(my camera makes slight noises very loud, sorry)

https://mega.nz/#!DXwC2RKA!QiCqc8XvafRg6bR5RdyQLK7JkmvDpHI-qK4FcgXfTpk

I can see it, the Z steppers have dust covers on the bottom that are stuck to the threaded rod and turn with it. This is why I went through so much effort to do heatmaps and level things perfectly with the tpu / wave springs under the heatbed standoffs. I thought this was the issue, or at least didn't want the curved parts you are describing. 🙂

Unfortunately, it doesn't affect this issue in my tests. After getting my bed leveled and down to 0.025mm variance across the entire surface, I was able to reset the machine (to clear mesh leveling) and do a print with auto home only. I confirmed before/after the test with G81 that mesh leveling was not activated (it'll error out if G80 hasn't been run first).

You do bring to mind an interesting anomaly I was having while leveling the crap out of my bed. I was seeing two things:

So this makes me wonder, is it possible that the Z steppers are fluctuating or not holding steady during prints? I can't see movement in mine, but at that level it may be hard to see?

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

I noticed something during my second print yesterday.

My Z couplers are moving from side to side even on straight lines. That means the Z axis is slightly moving up and down midprint. (My leadscrews are docked against the motor shaft in the Z couplers to minimize the effect of Z-Hop)

You probably cannot see this on your machines, since you are using integrated leadscrews, it's much harder to see there.

(The ones on the Z axis that connect the stock motor shafts with the standard threaded rods, Prusa only used these integrated without couplers)

Perhaps sticking a long piece of Tape on your leadscrews shows this effect.

The way they move from side to side when printing straight lines weirded me out at first, but i think these need to do that to compensate for a slight skew in the bed parallel to the X and Y axis.

But, they seem to move a bit more than my 0.07° skew that's displayed in the menu. Or why are they moving for print moves in the Z height above the first layer at all?

The fact that the Z axis are moving up and down mid print could very well explain the layer lines.

Z axis moves slightly up = thinner looking layer

Z axis moves slightly down = layer gets squished

This is not just for the first layer, it's for every layer.

Perhaps this is cause of a problem?

Overcompensating for skew correction?

Wouldn't it make more sense to correct a Z angle skew on the first layer, and leave all other following layers without this skew correction?

That way the layers on top of the first one are as consistent as they can be, leaving only skew correction from the X and Y axis.

I don't know where to post this, so i'll post this here and in scratch built MK3 topic.

I have noticed this on my mk3 when printing infill on large parts. Its easy to see if you have light shining of the motor caps. I always wondered if the issue we are having was due to an error in movement rather than a problem with extrusion. I didn't think about z-movement, but you may be on to something here.

Re: [Testers Needed] Inconsistent Extrusion

I noticed something during my second print yesterday.

My Z couplers are moving from side to side even on straight lines. That means the Z axis is slightly moving up and down midprint. (My leadscrews are docked against the motor shaft in the Z couplers to minimize the effect of Z-Hop)

You probably cannot see this on your machines, since you are using integrated leadscrews, it's much harder to see there.

(The ones on the Z axis that connect the stock motor shafts with the standard threaded rods, Prusa only used these integrated without couplers)

Perhaps sticking a long piece of Tape on your leadscrews shows this effect.

The way they move from side to side when printing straight lines weirded me out at first, but i think these need to do that to compensate for a slight skew in the bed parallel to the X and Y axis.

But, they seem to move a bit more than my 0.07° skew that's displayed in the menu. Or why are they moving for print moves in the Z height above the first layer at all?

The fact that the Z axis are moving up and down mid print could very well explain the layer lines.

Z axis moves slightly up = thinner looking layer

Z axis moves slightly down = layer gets squished

This is not just for the first layer, it's for every layer.

Perhaps this is cause of a problem?

Overcompensating for skew correction?

Wouldn't it make more sense to correct a Z angle skew on the first layer, and leave all other following layers without this skew correction?

That way the layers on top of the first one are as consistent as they can be, leaving only skew correction from the X and Y axis.

I don't know where to post this, so i'll post this here and in scratch built MK3 topic.

I have noticed this on my mk3 when printing infill on large parts. Its easy to see if you have light shining of the motor caps. I always wondered if the issue we are having was due to an error in movement rather than a problem with extrusion. I didn't think about z-movement, but you may be on to something here.

On MK2 the Z motors would get really hot while printing, and stay warm even when not printing. I asked PR and they said it was normal and due to high holding current. Maybe we need to increase the hold on MK3 somehow, unless this z movement is intentional by fw.

Re: [Testers Needed] Inconsistent Extrusion

I turned off mesh bed leveling and the z movement during the print did stop. So looks like that was the cause. But it did not change the vertical surface quality.

Re: [Testers Needed] Inconsistent Extrusion

I turned off mesh bed leveling and the z movement during the print did stop. So looks like that was the cause. But it did not change the vertical surface quality.

Awesome, good to have two people seeing this now. I took it a step further even and disabled MESH_BED_LEVELING in firmware, same deal, no movement but no difference.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

Awesome, good to have two people seeing this now. I took it a step further even and disabled MESH_BED_LEVELING in firmware, same deal, no movement but no difference.

Have you tried

M912 E__

DO NOT USE THIS IF YOU HAVE NO IDEA WHAT YOU ARE DOING. THIS CAN POTENTIALLY CAUSE DAMAGE TO YOUR PRINTER.

Default is E36.

63 = .96A

0 = 0A

I really don't understand this math myself, but MetaCollin posted it, and I am unable to check if this helps the stock extruder's inconsistency.

If you want to be "safe" lower the number to say, 31, and see if the extrusion inconsistency gets worse. If it remains the same, increasing it, likely will not help. If it gets worse... Increasing it, will likely, make it better.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: [Testers Needed] Inconsistent Extrusion

@Brigandier

Could you post your gcode somewhere so we could take slicer settings out of the equation?

Re: [Testers Needed] Inconsistent Extrusion

Awesome, good to have two people seeing this now. I took it a step further even and disabled MESH_BED_LEVELING in firmware, same deal, no movement but no difference.

Have you tried

M912 E__

DO NOT USE THIS IF YOU HAVE NO IDEA WHAT YOU ARE DOING. THIS CAN POTENTIALLY CAUSE DAMAGE TO YOUR PRINTER.

Default is E36.

63 = .96A

0 = 0A

I really don't understand this math myself, but MetaCollin posted it, and I am unable to check if this helps the stock extruder's inconsistency.

If you want to be "safe" lower the number to say, 31, and see if the extrusion inconsistency gets worse. If it remains the same, increasing it, likely will not help. If it gets worse... Increasing it, will likely, make it better.

Printer is already packed away again until I can get it relocated. Won't lie though, not familiar enough to get into the dangerous settings quite yet. 🙂

Considering your geared setup is pretty much the only setup here showing a difference, I dropped some change on a 27:1 NEMA 17. Should be in Tuesday, then I will start figuring out a way to adapt it to fit.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

@Brigandier

Could you post your gcode somewhere so we could take slicer settings out of the equation?

Sorry for the delay on this. Recreated the g-code from the top to ensure I didn't have any crazy settings floating around in it. This is a 50mm single wall cube with no infill, I made the following Slic3r changes:

With these settings, once you get past the skirt you'll notice each layer is exactly the same movementwise/extrusionwise.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

I turned off mesh bed leveling and the z movement during the print did stop. So looks like that was the cause. But it did not change the vertical surface quality.

Awesome, good to have two people seeing this now. I took it a step further even and disabled MESH_BED_LEVELING in firmware, same deal, no movement but no difference.

I actually did something a bit different that might be interesting to keep in general. I phased out the MBL over the first 1mm of Z. So first layer gets full MBL to get good bed adhesion and by 1mm it is off. I might need to change 1.0f to 1.2f since the first layer starts at 0.2mm. It definitely was using MBL on first layer and it was definitely not doing it later. I couldn't really eyeball the interpolation. Anyway, have a look and check my logic.

planner.cpp patch in void plan_buffer_line

#ifdef MESH_BED_LEVELING

- if (mbl.active){

- target[Z_AXIS] = lround((z+mbl.get_z(x, y))*axis_steps_per_unit[Z_AXIS]);

+ if (mbl.active && (z < 1.0f)){

+ target[Z_AXIS] =

+ (1.0f -z) * lround((z+mbl.get_z(x, y))*axis_steps_per_unit[Z_AXIS]) +

+ z * lround(z*axis_steps_per_unit[Z_AXIS]);

}else{

target[Z_AXIS] = lround(z*axis_steps_per_unit[Z_AXIS]);

}

Re: [Testers Needed] Inconsistent Extrusion

I turned off mesh bed leveling and the z movement during the print did stop. So looks like that was the cause. But it did not change the vertical surface quality.

Awesome, good to have two people seeing this now. I took it a step further even and disabled MESH_BED_LEVELING in firmware, same deal, no movement but no difference.

I actually did something a bit different that might be interesting to keep in general. I phased out the MBL over the first 1mm of Z. So first layer gets full MBL to get good bed adhesion and by 1mm it is off. I might need to change 1.0f to 1.2f since the first layer starts at 0.2mm. It definitely was using MBL on first layer and it was definitely not doing it later. I couldn't really eyeball the interpolation. Anyway, have a look and check my logic.

planner.cpp patch in void plan_buffer_line

#ifdef MESH_BED_LEVELING

- if (mbl.active){

- target[Z_AXIS] = lround((z+mbl.get_z(x, y))*axis_steps_per_unit[Z_AXIS]);

+ if (mbl.active && (z < 1.0f)){

+ target[Z_AXIS] =

+ (1.0f -z) * lround((z+mbl.get_z(x, y))*axis_steps_per_unit[Z_AXIS]) +

+ z * lround(z*axis_steps_per_unit[Z_AXIS]);

}else{

target[Z_AXIS] = lround(z*axis_steps_per_unit[Z_AXIS]);

}

Looks great to me. So I am guessing we can expect a jltx/Prusa-Firmware fork coming on Github with actual dev communication and support? 😉

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

The mesh bed leveling phase-out is a standard feature of both Marlin and Repetier (for years).... I had no idea that Prusa printers were not doing that automatically already...

Others have stated that the issue is present on mk2.5 machines as well which do not use the Einsy or tmc2130 drivers. So that is kind of good news to me since if it happens on the old electronics and also occurss with Titan extruders that the problem is more likely software than hardware.

Re: [Testers Needed] Inconsistent Extrusion

Here are some pictures of your gcode I just printed. If you need more pictures from different angles let me know but the layers looks perfect to me. What do you think? There was a couple of layer shifts, but I think I just need to tightened my x axle belt.