Re: Simplify3D settings for MK3

This should be it

Re: Simplify3D settings for MK3

This should be it

Thanks BLACKY.

Re: Simplify3D settings for MK3

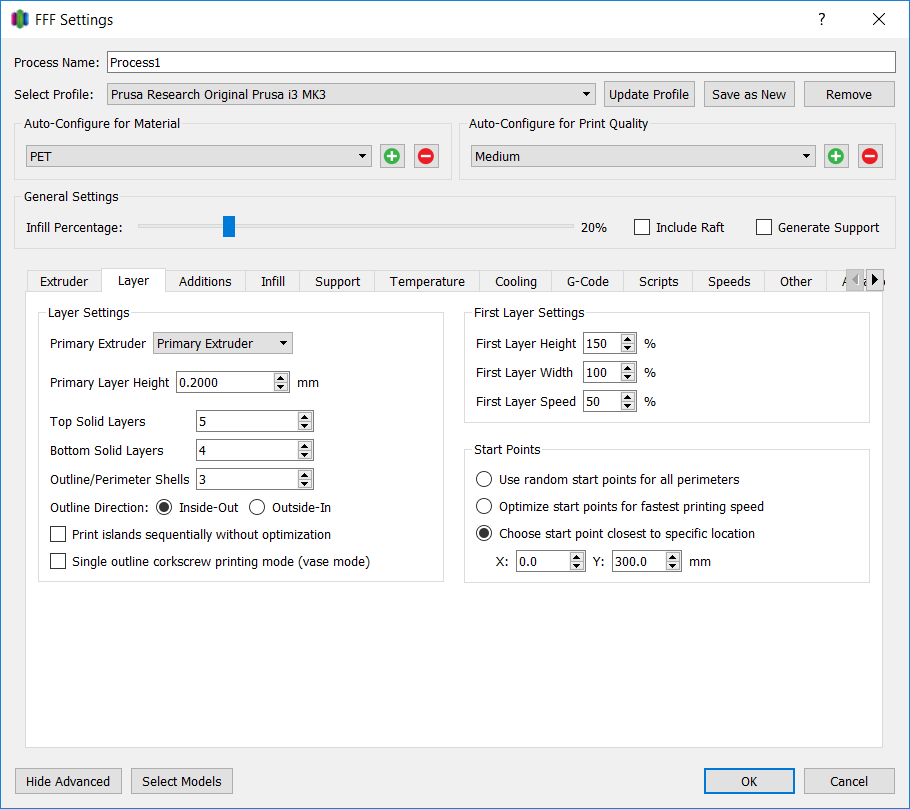

S3D bug? I found a problem when I went to print a Marvin in PETG, .2 layer and S3D default MK3 profile. After slicing it was going to air print(see below). By comparing to Slic3r and the old Mk2 S3D, I found the setting that was driving this was "first layer height". It was set to 150% if I lower it to 110% or less it would fix the problem. I was all ready consider changing this. I change all 3 first layer setting in line with the other profiles.

first layer height 100%

first layer width 95%

first layer speed 20%

The Martin came out great. But why did S3D set .3 thick first layer? Is this a S3D bug or a quirk of Marvin's STL?

Still need to do more experiments also considering changing extrusion width to .45

Re: Simplify3D settings for MK3

Hi,

Nice work with getting those settings tuned.

Does someone have working settings for bridges with ABS ? Can't get those to work properly.

Best regards... Szafran... MK3S + MMU2S + OctoPrint on DELL 3020m

Re: Simplify3D settings for MK3

Hi,

Nice work with getting those settings tuned.

Does someone have working settings for bridges with ABS ? Can't get those to work properly.

For abs I just set the fan to 20% and the bridges are fine. That is with just using a trash bag as the encloser.

Re: Simplify3D settings for MK3

Last try of this settings:

https://twitter.com/Neolker/status/963521145810112513

Re: Simplify3D settings for MK3

Hi. Have been playing with the setting in S3D but i cna't find the setting for acceleration and jerk. How do you set those in S3D?

Re: Simplify3D settings for MK3

add M204 / M205 in the postprcessing section

gcode command: http://marlinfw.org/docs/gcode/M205.html

download joes original profile. He used M204. replace it according to your ideas

Re: Simplify3D settings for MK3

i just used settings found in simplify3d 4.0 they are found in confiq wizard.

Re: Simplify3D settings for MK3

What would be causing the voids on the ends in the layers?

Seems to be at the start/stop points. Is there a setting I need to change.

Thanks for any help.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Simplify3D settings for MK3

Last try of this settings:

https://twitter.com/Neolker/status/963521145810112513

I tried this and while the results are better, my bench had some deformations towards the end on the chimney :\

Also, expected print time is off, any idea why?

Re: Simplify3D settings for MK3

Hi All,

Would you folks show some pictures of your first layer and some settings including the 1st layer H & W. My MK3 has a first layer that has gaps between every OTHER pass running these settings. I would like to close them up to make a solid first layer. Any settings suggestions will help.

Nozzle dia: .4

Primary height: 0.2

Extruder Multiplier: 1

1st Layer Height: 95%

1st Layer Width: 95%

Prusa Gray Filament

Live Z: Set with a slight 20% squish on top of filament

Any help would be very appreciated.

Thanks!

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Simplify3D settings for MK3

Would you folks show some pictures of your first layer and some settings including the 1st layer H & W. My MK3 has a first layer that has gaps between every OTHER pass running these settings. I would like to close them up to make a solid first layer. Any settings suggestions will help.

It would be better if you could make a picture of your first layer and post here. So people can suggest what might goes wrong.

Other way around will not help you because every printer and every filament is different.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Simplify3D settings for MK3

Hi There,

Well I'm not having any good success with S3D on my MK3.

The Prusa SD card Benchy is pretty good but a S3D sliced Benchy is terrible. Printed .200, Inland PLA, 100% fan after 3rd layer, 210'/65'.

What are the secrets to get this thing to work. Getting tired of changing the setup searching for the sweet spot. I have a good first layer.

Any help would be great...

Thanks.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Simplify3D settings for MK3

Hi There,

Well I'm not having any good success with S3D on my MK3.

The Prusa SD card Benchy is pretty good but a S3D sliced Benchy is terrible. Printed .200, Inland PLA, 100% fan after 3rd layer, 210'/65'.

What are the secrets to get this thing to work. Getting tired of changing the setup searching for the sweet spot. I have a good first layer.

Any help would be great...

Thanks.

Are you using the default from Simplify3D or another one?

I took the default S3D profile and tweaked it from there and haven't had any problems whatsoever. (I only tweaked some of the extruder settings, speeds, and temperatures)

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis

Re: Simplify3D settings for MK3

I am pretty sure I am using a latter Prusa MK3 profile from S3D.

Looking under a microscope, I find that the outside perimeter layer stops ends are crisp and precise but the layer start points kinda come in from the inside area and drag on with LESS material then begin to build to a normal layer. Start point extrusion is not beginning with full flow were it should.

Should I try slicing the part at a different rotation in S3D to see if the result is better. I have heard of this happening.

I have changed:

Layer Height: .200

Nozzle Dia: .400

Outside Layers: 2

Top/Bottom Layers: 3

Extruder Width: Set to manual with .400

My first layer is now gap free and has a 99% solid full print. The traces are thinner but are tight together.

1st layer height: 70

1st layer width: 75

1st layer speed: 35

Outline Overlap: 35%

ExtruderMultiplier: 1.05

Inside Out

No Coasting or Wipe

Retraction: 1.5mm

No retraction on layer changes

210/65 Inland PLA

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Simplify3D settings for MK3

Try an Extrusion Multiplier 0f .90. Seems like you are over extruding.

Re: Simplify3D settings for MK3

Thanks for the help!

I got it dialed in to a very good result. I am leaving the 1.05 EM set as is for now otherwise the first layer gets splits in the passes.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Simplify3D settings for MK3

I've noticed that the gcode S3D spits out results in the bed temp being set, a wait until the bed temp is right, then the extruder being brought to temp. This is different than what Slic3r does, where both bed and extruder are brought to temp at the same time.

S3D:

M140 S70

M190 S70

M104 S200 T0

M109 S200 T0

Slic3r:

M104 S215 ; set extruder temp

M140 S60 ; set bed temp

M190 S60 ; wait for bed temp

M109 S215 ; wait for extruder temp

Has anyone figured out a way to get S3D to do both at the same time? It makes preheating before a print go quite a bit faster. The Scripts tab only contains add-on stuff, it doesn't actually let you futz with the order of heating commands like Slic3r does.

Edit: I can haz web searching. https://forum.simplify3d.com/viewtopic.php?f=8&t=1105 is the exact thing I wanted, and it looks like if I turn off the checkbox for waiting for the heated bed to get to temp I get what I want. I'll give it a try on my next print!

Re: Simplify3D settings for MK3

You can also just copy the Slic3r way of doing it:

M104 S[extruder0_temperature] T0 ; this will take the layer 1 temperature for extruder 0

M140 S[bed1_temperature] ; this will take the layer 1 temperature for bed 0

M190 S[bed1_temperature] ; wait for bed temp

M109 S[extruder0_temperature] T0 ; wait for extruder temp

P