Re: seeking advanced testers

Yes, it was the tube. I thought that stuff is supposed to be "friction-free"! 🙂 I finally got it out by adding a small twist which finally popped it free.

Re: seeking advanced testers

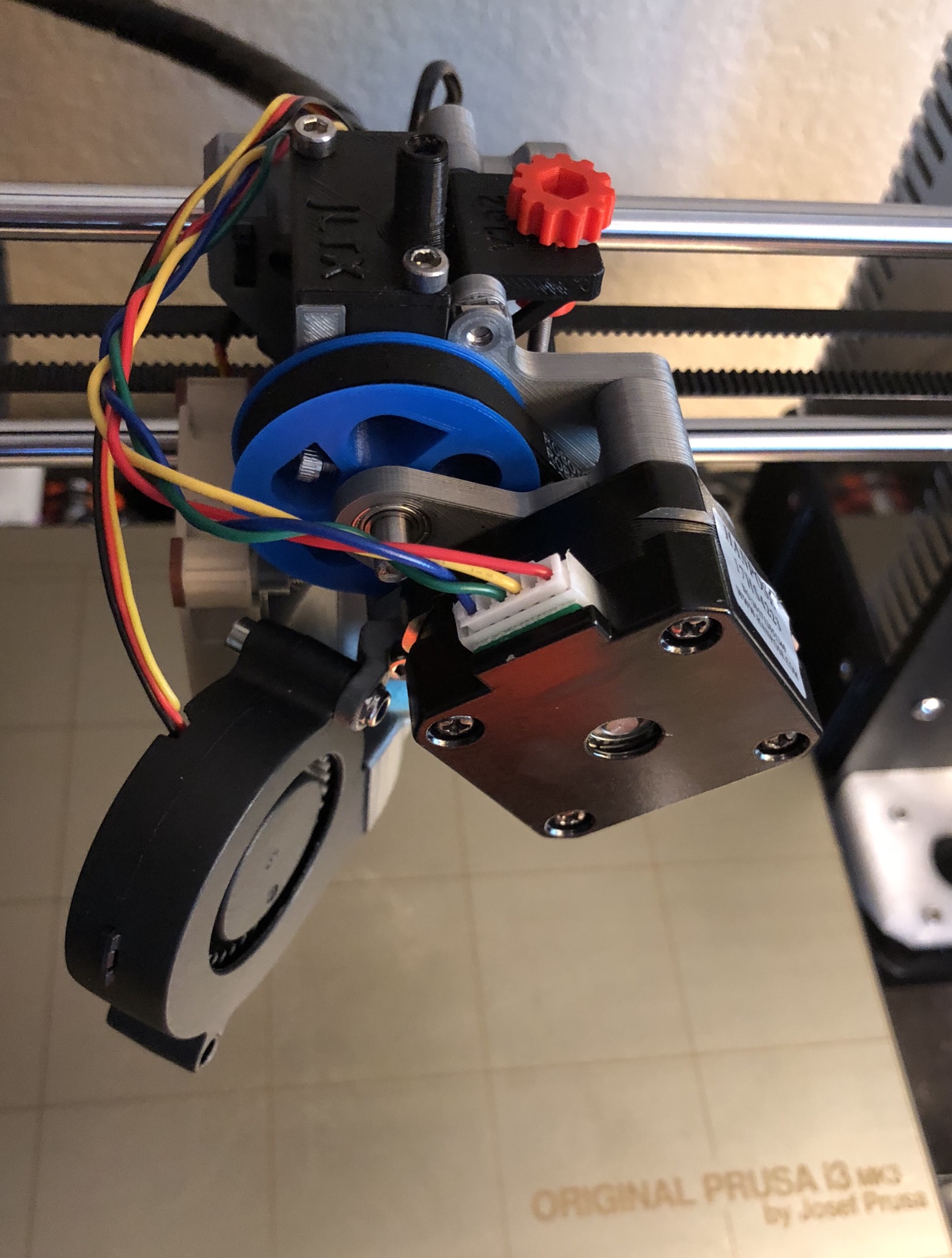

Making good progress. I hope to move to alpha2 stage and broaden testing. I am now printing upgrade parts using the new extruder itself. So won't require a back-up printer now.

Very happy with the tool free operation. Pinda height adjust is great. Gearing (3.5:1) is working nicely so far. Had to reset on the cooling (WIP). Many small improvements thanks to help from alpha testers.

I'll post a couple pics next.

Re: seeking advanced testers

Now we're talkin. Any sample prints with the 3.5:1 yet?

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: seeking advanced testers

I would be more than happy to print and try this out, that looks awesome. Did I skip over the STL's or is this restricted for now?

Re: seeking advanced testers

If you read my first post, I started with a blank sheet and some project goals. I ended up with a Titan-like solution, which makes sense since I believe they had some same goals.

Impressive stuff ! Great job so far !

Are you using aluminium bolts (rather than steel) to further remove weight from the moving mass ?

Re: seeking advanced testers

Now we're talkin. Any sample prints with the 3.5:1 yet?

I haven't printed any "quality" pieces yet, due to the lack of cooling system... which I trust JLTX to hit the nail on the head. His old one was the best... So I'm sure his new one will be better! 🙂

I would be more than happy to print and try this out, that looks awesome. Did I skip over the STL's or is this restricted for now?

He's currently in Alpha 1. And as far as I am aware, JLTX and Myself, are the only 2 fully assembled... For now! 🙂

If you read my first post, I started with a blank sheet and some project goals. I ended up with a Titan-like solution, which makes sense since I believe they had some same goals.

Impressive stuff ! Great job so far !

Are you using aluminium bolts (rather than steel) to further remove weight from the moving mass ?

As it currently stands the hardware is straight off the Mk3's extruder assembly.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: seeking advanced testers

Looks good for a alpha version 😀

btw the "Almost 200g less mass" is mainly because of the pancake stepper?

Word of advice from a longtime E3D Titan user, who also stalks E3D's forums:

E3D stopped bundling the pancake steppers with the Titan because the pancake stepper could not produce enough torque for the Titans in some cases.

The small steppers mostly have a 12.7 - 14 N-cm torque, and E3D and it's users in their forums found out that you'd need at least 18N-cm torque to drive a 3:1 gear Titan reliably.

That's why they bundle the Titans now with the 'compact but powerful' motors (40N-cm), and same size/weight as the stock Prusa ones.

With the pancake steppers some materials are unprintable, and even with regular PLA you'll have extruder clicking quite often (missed steps due to backpressure)

But i'm not better in this regard, i bought two 0.9 degree pancake steppers along with two regular 0.9 degree steppers for trying out how far i can push them with the new TMC2130 and their short overpeak current ability

Re: seeking advanced testers

Looks good for a alpha version 😀

btw the "Almost 200g less mass" is mainly because of the pancake stepper?

Word of advice from a longtime E3D Titan user, who also stalks E3D's forums:

E3D stopped bundling the pancake steppers with the Titan because the pancake stepper could not produce enough torque for the Titans in some cases.

The small steppers mostly have a 12.7 - 14 N-cm torque, and E3D and it's users in their forums found out that you'd need at least 18N-cm torque to drive a 3:1 gear Titan reliably.

That's why they bundle the Titans now with the 'compact but powerful' motors (40N-cm), and same size/weight as the stock Prusa ones.

Switching to the stock Prusa one will also make it easier for folks to make and use.

Re: seeking advanced testers

Looks good for a alpha version 😀

btw the "Almost 200g less mass" is mainly because of the pancake stepper?

Word of advice from a longtime E3D Titan user, who also stalks E3D's forums:

E3D stopped bundling the pancake steppers with the Titan because the pancake stepper could not produce enough torque for the Titans in some cases.

The small steppers mostly have a 12.7 - 14 N-cm torque, and E3D and it's users in their forums found out that you'd need at least 18N-cm torque to drive a 3:1 gear Titan reliably.

That's why they bundle the Titans now with the 'compact but powerful' motors (40N-cm), and same size/weight as the stock Prusa ones.

With the pancake steppers some materials are unprintable, and even with regular PLA you'll have extruder clicking quite often (missed steps due to backpressure)

But i'm not better in this regard, i bought two 0.9 degree pancake steppers along with two regular 0.9 degree steppers for trying out how far i can push them with the new TMC2130 and their short overpeak current ability

Correct. Most mass savings is the motor. I also lowered the mass center to line up with belt. But there is good savings in the design as well. Current state:

version: stock , new

motor: 270 , 130

printed parts: 111 , 75

HW (screws,etc): ~40 , ~25

Stock LDO is 35 N-cm. My gearing is 3.5:1 so a pancake with 10 N-cm should have roughly the same torque. I haven't had trouble yet with my 14 N-cm. I'd be curious to understand the 18 N-cm suggestion. I'm sure there is good info to be had.

Re: seeking advanced testers

If you read my first post, I started with a blank sheet and some project goals. I ended up with a Titan-like solution, which makes sense since I believe they had some same goals.

Impressive stuff ! Great job so far !

Are you using aluminium bolts (rather than steel) to further remove weight from the moving mass ?

I actually bought some ss capillary tubing which is 5mm OD and 3mm ID. It is much lighter. But, the OD is not precise, more like 5.03mm and won't fit the bearings. I would need to lathe it into submission. Hmm. Joan has a lathe. Anyway, I also found some titanium round bar that is 5mm spec but haven't ordered yet. You'd be surprised how hard it is to find tight tolerance 5mm shaft material. If you find any, let me know!

Re: seeking advanced testers

5mm tail spindle shafts for my stunt RC Helicopters usually have tight tolerances. Depends on how long you need the shaft.

Is this for your main gear shaft? I believe that it is not solid and tapped through.

Like this:

https://www.amainhobbies.com/sab-steel-5mm-tail-spindle-shaft-sabh0329-s/p275071

Re: seeking advanced testers

5mm tail spindle shafts for my stunt RC Helicopters usually have tight tolerances. Depends on how long you need the shaft.

Is this for your main gear shaft? I believe that it is not solid and tapped through.

Like this:

https://www.amainhobbies.com/sab-steel-5mm-tail-spindle-shaft-sabh0329-s/p275071

interesting. Need ~50mm length. I will keep that on my list to investigate. If you have a 105 bearing, see if it fits.

Re: seeking advanced testers

Out of curiosity, why did you go with a belt instead of the standard herringbone gear in a wade extruder reloaded? Quieter?

Re: seeking advanced testers

Out of curiosity, why did you go with a belt instead of the standard herringbone gear in a wade extruder reloaded? Quieter?

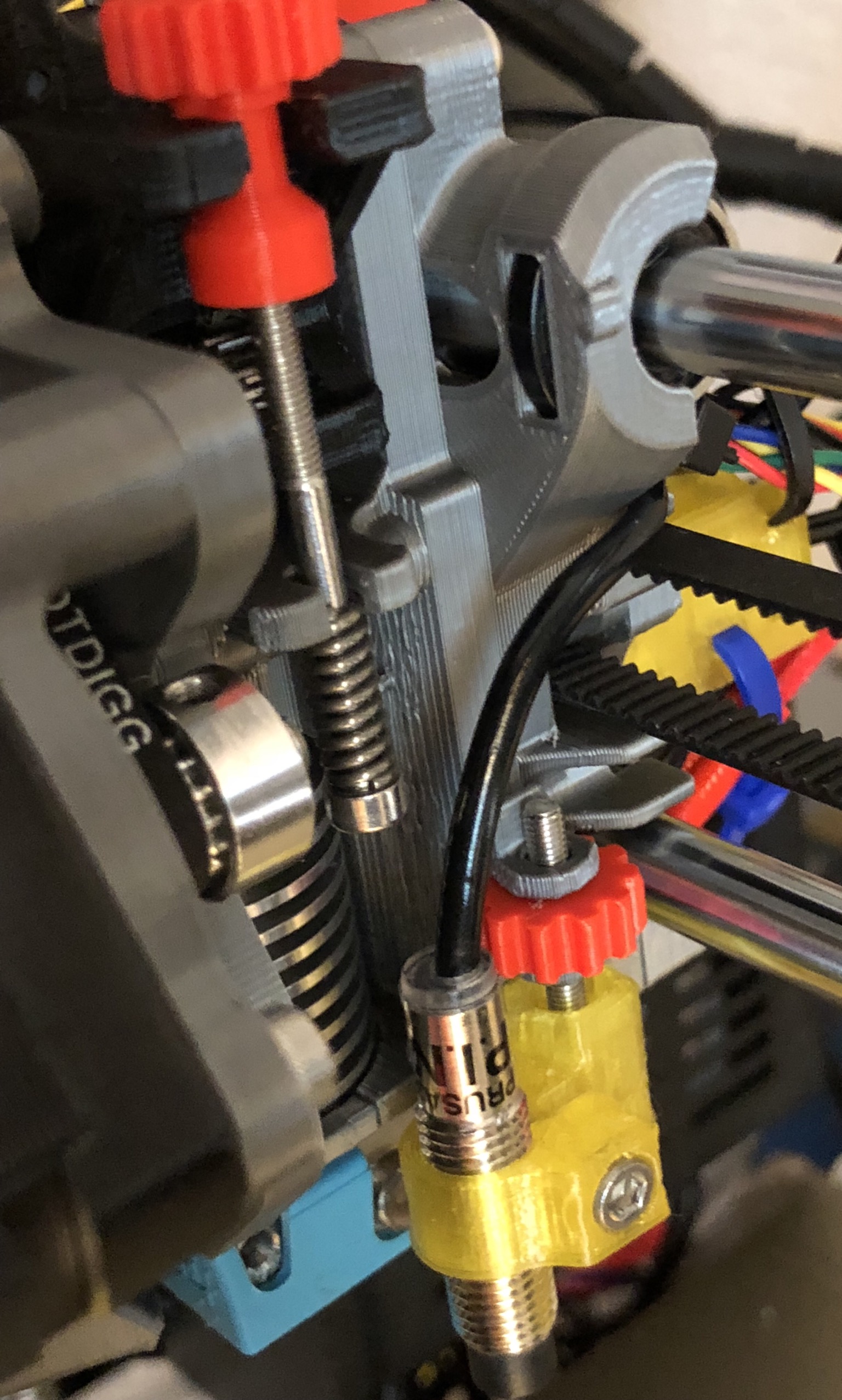

Excellent question. Here is a longer answer than you probably wanted.

Again, starting from blank slate and project goals, including RepRap ideal of make everything, I immediately landed on some sort of geared extruder. This solves a few problems. I can use a smaller, lighter motor yet recover torque, even exceeding stock. I can decouple the motor position from the filament path and put it lower down on the belt line to improve 2nd and 3rd order movement. I also decouple any heat transfer from the motor, through the Bondtech, to the filament. It increases the E steps/mm to hopefully improve print quality. So I started with gears because I can print them, and initially eschewed a belt. I learned all about gears, like different tooth profiles, addendums/dedendums, pressure angles, etc. The problem with gears is of course backlash. Helical gears help solve this but introduce axial pressure. So I looked at double helical (mistakenly called herringbone) which neutralizes this. I wrote a mathematically correct involute profile generator in my CAD sw to generate double helical gears with variable reach. So basically, I finally caught up with Wade. 🙂 I used prime number ratios and even looked at internal spur (think spirograph) to get the motor where I wanted.

The problem I ran into is that I could print a beautiful drive gear, but the pinion was very problematic. The whole setup works ok on larger scales like lulzbot uses, but I wanted it more compact to contain the mass offset and fit other structural elements I needed. Also, the double helical gear needs fairly precise positioning or maybe a floating pinion. Early prototypes were not robust enough for wide deployment and reliability (at least I as had designed it). So I revisited the belt idea. I quickly saw that it still provided all the benefits of the double helical gears but also solved a few more problems. It is much more tolerant of positional variance, is quiet, but more importantly is much more compact since the teeth are on a 2mm pitch. With a common 16T pinion I could achieve a good gear ratio in a small package. Conveniently I had already come up with a good GT2 profile in my comfortFit pulleys. I found that with scaling to the larger radius and an anisotropic scale I could get a great print with a std 0.4 nozzle. I finally had my answer. But I reserve the right to change my mind.

So far I'm very happy with the performance. The belts are pretty cheap so I'm going to pretend it doesn't violate the RepRap spirit.

Re: seeking advanced testers

@jltx posted:

I actually bought some ss capillary tubing which is 5mm OD and 3mm ID. It is much lighter. But, the OD is not precise, more like 5.03mm and won't fit the bearings. I would need to lathe it into submission. Hmm. Joan has a lathe. Anyway, I also found some titanium round bar that is 5mm spec but haven't ordered yet. You'd be surprised how hard it is to find tight tolerance 5mm shaft material. If you find any, let me know!

Don't know if this helps, but ran across these www.aliexpress.com/item/100mm-Length-TA2-Industrial-Pure-Titanium-Hollow-Tube-Polished-Ti-Pipe-SIZE-3mm-ID-5mm-OD/32785533025.html?spm=2114.search0104.3.54.f60b3aa3TA0Dsh&ws_ab_test=searchweb0_0,searchweb201602_4_10152_10065_10151_10344_10068_10130_5722815_10324_10342_10547_10325_10343_10546_10340_10341_5722915_10548_10545_5722615_10697_10696_10084_10083_10618_10307_5722715_10059_5723015_10534_308_100031_10103_441_10624_10623_10622_5722515_10621_10620,searchweb201603_25,ppcSwitch_5&algo_expid=09f08669-999b-489e-959a-07904e25c760-8&algo_pvid=09f08669-999b-489e-959a-07904e25c760&transAbTest=ae803_1&priceBeautifyAB=0

. No idea if they'll be more precise, but they should be lighter 😀

Re: seeking advanced testers

The problem with gears is of course backlash. Helical gears help solve this but introduce axial pressure. So I looked at double helical (mistakenly called herringbone) which neutralizes this. I wrote a mathematically correct involute profile generator in my CAD sw to generate double helical gears with variable reach. So basically, I finally caught up with Wade. 🙂 I used prime number ratios and even looked at internal spur (think spirograph) to get the motor where I wanted.

So far I'm very happy with the performance. The belts are pretty cheap so I'm going to pretend it doesn't violate the RepRap spirit.

You are correct regarding the issue with gears is backlash.

However on the E-Axis it's 100% irrelevant.

Let's assume you have 0.1mm of linear backlash on the extruder assembly with your gear.

All you would need to do is increase retraction by 0.1mm.

When the gear feeds "forward" to feed the filament back, it will return to the exact same position that it was at, before the retract. 😉

If you were to run gears for the linear motion... You would need to deal with backlash... which is much scarier than it sounds. 🙂

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: seeking advanced testers

If you were to run gears for the linear motion... You would need to deal with backlash... which is much scarier than it sounds. 🙂

for me the movement of filament seems quite linear 😉 😀

Re: seeking advanced testers

for me the movement of filament seems quite linear 😉 😀

... Bi-Directional... 😉

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: seeking advanced testers

5mm tail spindle shafts for my stunt RC Helicopters usually have tight tolerances. Depends on how long you need the shaft.

Is this for your main gear shaft? I believe that it is not solid and tapped through.

Like this:

https://www.amainhobbies.com/sab-steel-5mm-tail-spindle-shaft-sabh0329-s/p275071

interesting. Need ~50mm length. I will keep that on my list to investigate. If you have a 105 bearing, see if it fits.

oooh just missed it. I grabbed my spare and the shaft is 45mm long. Its tapped on both ends but is solid the rest of the way. Its hardened steel weighing in at 3.3 grams by itself.

The spindle bearings it uses are not marked themselves but the dimensions are 5x10x4.

Here is pic.