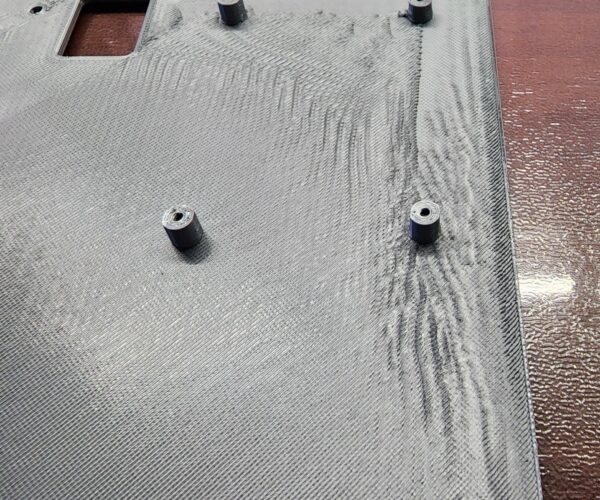

Rough surface in one region

One area of my print is a very rough surface with steps in it. About 10-15% of the surface. The bottom side looks perfect. The filament is the silver PLA that shipped with the printer. Any idea of the cause and corrective action?

Model: i3 MK3s+

RE: Rough surface in one region

Even the top of the 'pegs' are looking rough. Try adding one or 2 additional 'top layers' and increasing the heat 3 degrees.

RE: Rough surface in one region

What infill type and percentage are you using ? The larger a flat top surface the more infill it generally needs to avoid sagging. More top layers can also help as Jimbo mentioned as that allows more layers for the top surfaces to correct.

If you want further analysis of potential other reasons then the best way is to save your project from Prusa Slicer (File>Save project as), then take the resulting 3mf file and ZIP it up and attach it. Must be zipped or the forum wont accept the file. A project 3mf contains not only the model but EVERY setting you are using so it allows other to slice with exactly the same results and examine the various print preview options.

RE:

I am relative new to 3D printing. Done < 10 prints of my own design.

Therefore, I am just using the slicer defaults. This is 15% infill for the Prusament PLA filament. If I understand the print settings, it has Horizontal shells - top layers = 8. 80% - 90% of the large surface looks fine.

After I check the fit, I will print another one. I see that all the holes are slightly undersize. 0.187 is 0.180, 0.140 is 0.130. I may adjust the model or just ream the holes.

RE: Rough surface in one region

Holes being undersized is pretty normal. There are a few slicers where you can set expansions but given how they slice, that holes are made of of short straight sections on most models when they are exported to stl so 'cut the corners' even before the slicer gets to them its usually much easier to run a drill bit through them if you need them true to size.