Prusament = quality issue?!

Hey all,

first of all, two month ago, I got an mk3 and was (and am) impressed by the print quality out of the DIY box. In the kit included was a spool of 'Silver Prusament PLA'. The prints with it were good, up to today. What happend today has NEVER happend before in my ~3 years of printing and is an absolute nogo!

Please look at the attached picture.

I was wondering, why my extruder motor was clicking/jumping the filament (after 14h of printing, 2 hours to go). So I tried to pause the print and have a closer look. I couldn't unload the filament. At this time I didnt know why. I tried unloading with manual help, no luck. I opened the side pannel and while trying to pull it out, it broke.

Therefore I had to cancel the print and uninstall the heatsink, as I couldn't reach the filament, as it broke around teflon tube entrance height. Even after uninstalling I couldn't get it out, so I had to pull apart the whole heatsink (during this process I broke the heatbreak (my fault)). The Teflon tube was sitting tight, even after removing the plastic ring, so while trying to pull it out, I had to use pliers and wrecked the tube (pushed together). Then, I coiuld finally get the filament out.

The blocking was due to bad filament glueing. On the picture, you can see, that (probably) two loads of filament were glued togehter. Instead of discarding the roll, they shipped this roll to customers, in this case me. You can see the tooth marks above the glued area, were a lot of force from the extruder was necessary to push the filament in the teflon tube. The glued area finally got stuck in the heatbreak, resulting in this problem.

It cost me around 1.5 h to fix everything. Luckily, I got a replacement heatbreak, heatsink and teflon tube. The broken heatbreak is stuck in the heatsink atm (but I will get it out), so it cost me a heatbreak and a teflon tube (and this little plastic ring between heatbreak and teflon tube)

You can clearly see on the picture, how bad the two loads of filament are glued together. As mentioned before, the printing quality with Prusament so far was very nice, but this was just a nogo and never happend before with my other printers/spools.

Maybe the Prusa team can help out. As mentioned, so far, it was a very nice printing quality with this PLA Prusament in silver (and I would have already bought some PET in orange, but it was sold out; Great color!; oh available now **drooling**!).

This was (most probable) a production mistake, which mustn't happen.

Happy printing,

Test53

Aunt Edith saw a an ID on the filament roll. Attached as second picture!

Re: Prusament = quality issue?!

Hi Test53,

have you discussed this in 'online chat'

Joe makes a big issue about rejecting defective filament!

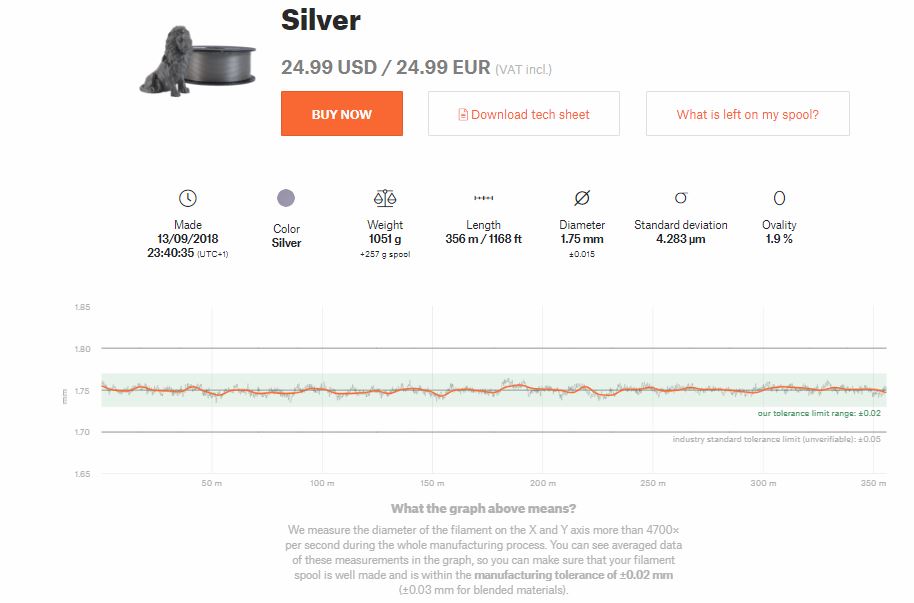

the online report for your filament looks good!

so if that knot has snuck through the measuring station, they need to know about it!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Prusament = quality issue?!

Thanks for your reply @joan.t!

It should work fine now till the end, as the new 'load' (that was glued to the old 'load') is beeing printed (no need for spool replacement). I've already printed it 2/3 through. I will let the chat know about it, though. A pity about the heatbreak. though! (had to drill a hole inside the broken heatbreak (3.5mm) first, put a long screw inside from the top of the sink, put it in the oven @230°C for 10 min, and the I could finally screw the broken heatbreak out of the sink)

Just ordered PETG Orange and white and will give it a try.