RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I didn’t realize they are making a branch of the software but I’m also referring to the cloud requirements and the hardware. Still it’s likely my next printer especially if a larger version is released.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

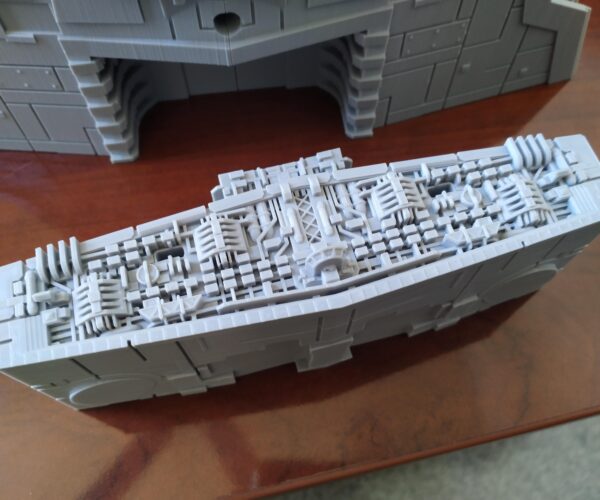

My X1 Carbon showed up yesterday and I thought I'd give some feedback for those pondering the question in the poll. For background, I have a Mk3, no S, no +. It has a few mods to it that were done relatively early in it's life -- nylock bed leveling, y axis rod holders, y axis bearing holders, y axis motor mount. More recently the heatbreak was swapped for a standard E3Dv6. That's it. The Mk3 has been quite reliable and produces very nice quality prints. For context...

That is a 0.25mm nozzle with 0.15mm layers. The entire print took 1368 hours of printer time and there was exactly one print failure in the entire print.

So, here are my thoughts about the X1 Carbon.

- It's bloody loud. Not just the motors, the fans are too. Don't think you are going to have an X1 in the same room with you. Don't think you are going to have it in an adjacent room and not here it. Now, I will be the first to admit, I'm spoiled by the noise level of the Mk3. I lives in a Lack enclosure, behind me in my home office. I work from home and spend plenty of time on conference calls. I have no problem with the Mk3 running while I'm working. Absolutely no way I could do that with the X1. Yes, I had watched various reviews and knew the X1 was going to be louder, but until you hear it in person...

- It's fast. It's very fast. In normal speed, it's about 2.5x faster than my Mk3. I'm currently printing a bracket. On the Mk3, in with a 0.4mm nozzle and 0.2mm "speed" settings in Prusaslicer, the Mk3 would take approx 3hrs. The X1 is 1hr 17m. That is printing time. Others have noted that the X1 has a pretty lengthy pre-print routine. This is true. It adds 8m 18s to the total time on the X1. I run my Mk3 with full 7x7 leveling and a nozzle pre-heat to 170 prior to leveling. It doesn't add eight and a half minutes, but it does add a significant amount of prep time to my Mk3 runs. I ordered the AMS with the X1 and the prep time is pretty much identical whether it has to switch filaments or not, to start the print. If I had to switch filaments on my Mk3 to start a print, the X1 would be several minutes faster.

- Print quality. This is currently a mixed bag. I have not had time to really tinker with the X1 settings at all. I've run some PLA prints with the slicer using the "strength" settings. It resulted in the prettiest first layer I've ever seen. Beats anything I've gotten from the Mk3 in terms of consistency and smoothness, and my Mk3 generates really nice first layers, compared to a lot of what I seen posted. Top layer, on the other hand, leaves a good bit to be desired. Now, I don't know if this is because of "strength" mode, or something else. Reviews and comments I've seen have said that the Bambu slicer does seem to have problems generating pretty top layers. Other than the top layer, the print quality appears to be excellent. Layers are very nice and consistent. No signs of extrusion variation. For those that have a very well tuned Mk3 -- no VFAs.

- Setup. I bought my Mk3 as a kit, so building it was part of the "experience". If you compare the prebuilt Mk3 to the X1, the X1 will be a bit more work to unbox, but you don't have to do any first layer calibration for the X1. Time wise, it's probably about the same for a prebuilt Mk3 and an X1, the steps and process are just different between the two.

- Print area. This is one place where the banner specs of the X1 are a little misleading. If you have extrusion calibration turned on, it used the front and front left of the build plate to print the calibration pattern. With this enabled, the build area is more like 256mm x 190mm or 205mm x 225mm depending on where you put things. You can, of course, turn on extrusion calibration and use the full bed area, but then you are giving up one of the other headline features of the printer.

- Maintenance. This one will take time. As noted, I bought my Mk3 as a kit and did the assembly. I know exactly how it goes together and how to get it apart. Parts are generally available for it. It uses a E3D hot end. The X1 is, as many have noted, proprietary. As long as parts are available, that's not necessarily a huge problem from a usability standpoint. I've got upwards of 2000 print hours on my Mk3 since it's last major overhaul. It's due up, but still turning out high quality prints. That is what I will be measuring the X1 against.

- Appearance. This is totally subjective. The X1 looks like a commercial product. Fit and finish, at least on mine, is quite good. It would not look out of place sitting next to the Markforged Onyx we have at work. The Mk3 has a more "hobbyist" appearance. That said, my wife was sitting in my office as I was testing out the X1 and made the comment "It's much less interesting to watch." The solid sides and smoked glass of the X1 mean that you can't really just sit and watch it print. The Mk3, in the Lack enclosure has very good visibility and any time I am on a conference call, where it is running in the background, someone asks what I am printing within moments of the call starting.

I ordered the AMS with my X1. I'm not looking to do fancy multicolor models with it. However, the ability to do labels in prints and the occasional multicolor print will be appreciated. Almost as nice is the ability to keep multiple colors or materials handy and not have manually swap them out.

RE:

Thanks for a balanced review. Some of the posts in this thread have become a bit too zealous for me--one side or another— so it's refreshing to read a no-nonsense report.

RE:

[snip]

- It's bloody loud. Not just the motors, the fans are too. Don't think you are going to have an X1 in the same room with you. Don't think you are going to have it in an adjacent room and not here it. Now, I will be the first to admit, I'm spoiled by the noise level of the Mk3. I lives in a Lack enclosure, behind me in my home office. I work from home and spend plenty of time on conference calls. I have no problem with the Mk3 running while I'm working. Absolutely no way I could do that with the X1. Yes, I had watched various reviews and knew the X1 was going to be louder, but until you hear it in person...

- It's fast. It's very fast. In normal speed, it's about 2.5x faster than my Mk3. I'm currently printing a bracket. On the Mk3, in with a 0.4mm nozzle and 0.2mm "speed" settings in Prusaslicer, the Mk3 would take approx 3hrs. The X1 is 1hr 17m. That is printing time. Others have noted that the X1 has a pretty lengthy pre-print routine. This is true. It adds 8m 18s to the total time on the X1. I run my Mk3 with full 7x7 leveling and a nozzle pre-heat to 170 prior to leveling. It doesn't add eight and a half minutes, but it does add a significant amount of prep time to my Mk3 runs. I ordered the AMS with the X1 and the prep time is pretty much identical whether it has to switch filaments or not, to start the print. If I had to switch filaments on my Mk3 to start a print, the X1 would be several minutes faster.

- Print quality. This is currently a mixed bag. I have not had time to really tinker with the X1 settings at all. I've run some PLA prints with the slicer using the "strength" settings. It resulted in the prettiest first layer I've ever seen. Beats anything I've gotten from the Mk3 in terms of consistency and smoothness, and my Mk3 generates really nice first layers, compared to a lot of what I seen posted. Top layer, on the other hand, leaves a good bit to be desired. Now, I don't know if this is because of "strength" mode, or something else. Reviews and comments I've seen have said that the Bambu slicer does seem to have problems generating pretty top layers. Other than the top layer, the print quality appears to be excellent. Layers are very nice and consistent. No signs of extrusion variation. For those that have a very well tuned Mk3 -- no VFAs.

[snip]

Thanks for sharing your thoughts, they are pretty similar to my own experience. A couple of pointers: The long initial print startup can be somewhat reduced once you've used it a couple of times. Turning off flow calibration and leveling is fine as long as its had at least 1 calibration on the same surface - this knocks off about 4 minutes (sometimes slightly more or less).

I also found swapping over to using the SoftFeaver fork gave me better top layers. I dont know what it does differently but I assume its just settings that could likely be tweaked in bambu studio, likely the number of top layers. I did give ironing a try but theres still some work to be done in bambu studio as it was pretty hit and miss. I'm not to worried though, the updates have been coming thick and fast, some of their updates even look to have made it back into PrusaSlicer so the whole opensource side of things is working pretty well now.

A couple of months in the noise level is the only major gotcha in the chain for me now. I've been able to reduce it a fair bit by placing it on a solid oak table (i.e no hollow areas to amplify sound like we get with the lack enclosures). I've also recently placed a thick and very heavy washing machine mat under it (basically a very chunky rubber mat) under it with a paver on top of that and that made a huge difference. Most of the noise is now from the fans, but if you print PLA you dont need the aux fan running at all - turning that off alone feels like it makes a big difference. I'd say I've managed to half the sound on it, it's still loud but nothing like it was out of the box. I do wonder if having it in a larger enclosure around it which is padded with noise dampening foam might help but wont have the space to try this until later this year.

Proud owner of an original Prusa Mendel i2, original wooden frame i3 and now a mini+

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

For the record, I will almost certainly end up with a PrusaXL. The biggest draw for me there, is the ability to swap nozzles without haven't to do all the work involved on a Mk3 (or the X1 for that matter) and the ability to combine materials with different print temps. Had the XL been deliverable in a 2-4 week timeframe, it would have been a real toss up between the XL and the X1.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

Nice review. I agree. As for ironing, make sure to switch from the default crosshatch to cubic or gyroid. Some people have also suggested setting 5 top layers. The issue seems to be getting the top very flat prior to ironing.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

Quite at the beginning of the thread I posted an image of my first PETG print with artefacts. This was some weeks ago, but I still struggle with the same thing.

The printer prints the benchy flawless in PLA. But I do not manage to get PETG prints without artefacts. I tried almost everything:

Different profiles, much slower speed, increased temperature, different settings for retraction, different orientation, flow calibration with room lights turned off, I set the belt tension and cleaned the carbon rods, I set the printer back to factory defaults and recalibrated everything... It does not work. You can see in the image attached how poor the PETG prints look like.

I'm in contact with Bambulab support now, but so far without success...

Something must be wrong with my machine. No way Bambulab would have released the X1 Carbon with those artefacts.

I knew I could end up trouble shooting, and that is exactly what happened. But since I don't need the printer commercially, I can deal with that.

Other than my issues, there are a few things which are annoying:

- The machine is EXTREMELY loud. I came from an ancient ultimaker, but the X1 tops it! No way you can print over night without a mod. I do not know what they smoked, but in the regular PETG profile the chamber fan is set to 100%. It sounds as a starting airplane. The motors are loud as well, but ok, you can use silent mode or turn acceleration down and then noise level improves. --> They need to fix that. As soon as there is a reasonnable fan mod available, I will do it.

- The printer is fast but is wasting too much time for preparation. I did not use a stop watch, but the printer is doing all kinds of unuseful axis movement and calibration procedure. If you do a short print you loose way to much time. For a long print it obviously does not matter too much. --> I hope they will improve this by software update.

- The printer is wasting too much area for flow calibration. You can disable that, but because there is only 1 calibration stored (at least this is what I read), you do not have a proper calibration when changing material. --> They need to upgrade software. There must be a possibility to store a calibration for a specific type of material which can be chosen.

- The printer is always printing a line near two borders of the build palte. I don't know why, but I do not like it. Because it always prints at the exact same place, wear of the build plate is quite uneven. Why not just print a line around the object, the same way Cura does it?

- In Bambulab studio you can only change the printing temperature via profile. I would like to be able to change temperature without creating (or updating) a new profile.

- When using the AMS filament is unloaded after every print. I don't see why this is done because when the action takes place, the printer does not know yet which filament will be printed next. The result is a waste of time and a waste of material. -> I hope they add a checkbox so you can choose if the AMS automatically unloads the filament after each print or if the current material stays loaded until you change the material.

Other than that I think the Bambulab X1 is a fantastic machine with huge potential for improvements by SW update. Despite the current issues I have, I would buy it again without hesitation.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I am just adding my 2 cents into this. I personally don't have either printers and can only go off what I have seen with the two but i have a little over a year 3d printing and have gained a pleathera of knowledge over that time. I also have a small background in cad, cnc, design and fabrication. I am very skeptical for a couple of reasons. The first being that these are DJI engineers and staff and anyone that has owned anything DJI has seen first hand how fast they will drop support or have you update to only to realize that they just put intentionally bugged it to fail so you'll buy more products (DJI goggles v2 also sold a bunch of caddx vistas' to say after less than a year that they will not be supported.) This company could literally stop selling replacement parts or stop selling the important once's and your out of gas like they have already stopped selling the lidar sensor and a fair amount of parts are sold out or not available. Also I don't think they anticipated for this amount of units being sold and are still only able to make so many of them without quality going to crap fast.

Another issue I have is the printer is using carbon fiber rails which are showing to wear out rather fast and could contribute to toxic dust build up inside the printer, I have also heard about people printing with abs filament and having residue all inside the machine with no way of getting it off so after a few hundred hours of printing it will be completely covered in gunk PERMANATELY. I dont see any of these machines being around in 5 years and i see a lot of prusa's still hammering out prints.

In my opinion its like buying a Awesome Muscle Car that is sure to impress and is tough as nails vs buying a new car that also seems nicer is a 2 stop lights away from going to the crusher if they even crush them probably all plastic so no valuable contents.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

JUST WANTED TO ADD THAT THE DATE FOR ALL OF THESE POST SEEMS VERY ODD LOOKS LIKE THERE POSTING IN DECEMBER 2 2023

WHEN IN REALITY ITS FEBRUARY 12 2023

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

Don't forget that the dates in this forum are European format so 12/2 is not 2nd of December but 12 of February.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

That is just pure speculation .. it might happen.. but it also may not..

I think you look at historical data.. In the past 3 years, they've started from ground zero and developed a core XY printer, with enclosure (not sure if it vents as well as it should) with camera, network communication interface, all metal hot end, with innovative Lidar for auto-configuring the first layer and print speeds twice those of existing core xz. All in the severe stock shortage that everyone has dealt with. I expect them to have more maintenance simply because it is a first release.. and no product.. (including the XL) will be great until rev 3.. and they've price their product much lower than existing offerings. I just can't see them packing it in after 6 mo. To me, it is not a huge cost so the risk is minimal, but still there. I see some problems with some faulty wiring .. but some have hundreds of hours of printing by now.. By no means am I overly enamored with it.. but I don't see all that functionality available in anything else in that price range. So it might be a good deal for a local maker space that wants a few, high performance printers at a reasonable price. And have you ever driven a manual in those awesome muscle cars.. they were crap.. give me a shiny Japanese manual transmission any day.. 🙂

I think if you are doing a ton of ABS, you really need a different beast .. full ventilation.. commercial grade.

In my opinion its like buying a Awesome Muscle Car that is sure to impress and is tough as nails vs buying a new car that also seems nicer is a 2 stop lights away from going to the crusher if they even crush them probably all plastic so no valuable contents.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

The printer prints the benchy flawless in PLA. But I do not manage to get PETG prints without artefacts. I tried almost everything:

I only print with PETG and have no artefacts on any of my prints. I'm using Easy PETG from Fiberlogy which I have found to be best even on my MK3+ machines.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

I have done one print with PETG and it turned out well. I used Matterhackers translucent blue Build series.

I have had several drones. They constantly went into trees and buildings until I got a DJI. DJI dominates the drone market and it is easy to see why. They offer advanced technology with great software at a good, if not cheap, price. The DJI connection is why I backed the Bambu Lab Kickstarter.

I had a Z-axis fail this morning. I secured the fan to the side again and moved the build plate a little. It then worked. I will try to fully secure the fan this weekend. Also, there is a Wiki article about moving the bed slightly forward to prevent a bump causing a Z-axis fail. I will check the spacing. This is why I say this printer isn't plug and play. Then again, it isn't like what I see Ender owners going through.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

What temperature and speed settings do you use? I increased temperature to 280° and reduced outer wall speed to 50mm and still get artefacts!

RE:

Quite at the beginning of the thread I posted an image of my first PETG print with artefacts. This was some weeks ago, but I still struggle with the same thing.

The printer prints the benchy flawless in PLA. But I do not manage to get PETG prints without artefacts. I tried almost everything:

That sure looks like a model related issue as the failure is duplicated in every model. I might try to redo the model in fusion 360 and reprint and see what it is doing.. Or get some similar models from other sources and print in PETG and see if you have similar failures.. maybe look at the slicer as those failed areas occur.. There is something wonky there.. Not sure that would be a printer issue. You shouldn't need to print hotter than 225/85 at what would be a normal speed for a prusa.. (maybe zip up the model and others can look at it) Now printer settings can affect output.. so not sure how we'd capture that..

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

What temperature and speed settings do you use? I increased temperature to 280° and reduced outer wall speed to 50mm and still get artefacts!

I use the default settings for Generic PETG supplied by Bambu and it all looks great.

Try slicing and printing a different model. If that doesn't work then I'd start looking at the filament.

RE:

I create the models with a commercial software. I have tried various models with similar issues. But why should it be a slicer issue if the same models turn out perfectly fine with PLA, even in ludicrous mode?

I will not use this thread for trouble shooting. I documented everything in the Bambulab forum: https://forum.bambulab.com/t/bad-quality-when-printing-petg/4671

I don't expect anyone to read the whole thread but people interested could scroll through the images.

At the moment I don't know yet if my issues are related to my printer, the X1 in general or the slicer.

If I have to bet right now I will say it's a software bug. In certain situations the flow rate seems to be missaligned to the movement of the printing head.

I don't think it is the filament for two reasons: 1) it is a very common filament, 2) the two opposite faces with mirrored geometry differ quite heavily. If it were the filament, you should get either random artefacts or artefacts which always occur with the same geometry of the print.

So it would be interesting for me if someone got good results with the X1 and PETG from prusa. If somone would provide me a 3mf file I would print it!

RE:

I read the entire forum post for bambulab as I'm hoping to get some of these printers for a local College. I really feel for what you are going through.. and my career in electronics/computer design always confirms the same thing.. they are great when they work.. but...

After only a year of printing.. and not really having had to delve into 'pressure advance' vs temp vs speed .. I am woefully inadequate even to offer suggestions after those who have helped you on the Bambu forum.

I can see that many can print PETG fine, so I don't think it is a printer problem, when the printer has everything in it working properly .. it does not seem related to filament at all.. the errors are very repeatable, which points to a computer related issue.. maybe a setting.. but doesn't even look like that.. I almost wonder if a bug/corruption in either your slicer software or firmware in X1C.

I think I might be tempted to reflash the entire firmware, if that's possible.. and delete the slicer and reinstall from the 'net'. Maybe even better.. get a different computer to install the slicer, slice and send.. then at least you can rule out that.. When computers attempt to do everything for you automatically, there is a double-edged sword.. where.. when it doesn't work, it is twice as complex to fix as one, like the voron, where you've set up everything yourself..

The fact that others can't easily reproduce the severity of your artefacts leads me to believe that it would be difficult to help, since the issue doesn't seem to occur on most printer. I'm very interested if you get it fixed, but I suspect you'd need to be a bambu lab tech to figure it out. Best of luck.

I will not use this thread for trouble shooting. I documented everything in the Bambulab forum: https://forum.bambulab.com/t/bad-quality-when-printing-petg/4671

I don't expect anyone to read the whole thread but people interested could scroll through the images.

RE:

Just as an addendum.. (timeout on editing last post).. I have come to prefer printing PETG over PLA because my prints tend to come out better. I have used 3 or 4 different brands, many, many different colors over several hundred hours.. I've bumped up the print speed up to 200% in places.. and in all that I've had my share of failures.. but always related to something I've done or not done in a setting. I've never seen artefacts like what you have. No PRUSA PETG as the cost in Canada is much too high.

RE: Prusa MK3S+ vs Bambu Lab X1 carbon

Another issue I have is the printer is using carbon fiber rails which are showing to wear out rather fast and could contribute to toxic dust build up inside the printer, I have also heard about people printing with abs filament and having residue all inside the machine with no way of getting it off so after a few hundred hours of printing it will be completely covered in gunk PERMANATELY. I dont see any of these machines being around in 5 years and i see a lot of prusa's still hammering out prints.

I do not consider to buy this printer at all.

In Germany i can buy nearly 2 MK3S+ as kit for the price of one Bambulab X1c.

Regarding the carbon rods, somewhere i read they should not be greased? How should this work? Are there ball bearings rolling on the rods surface?

These carbon rods are not available as spare parts. Also no electronics / boards available as spare parts...