Preventative Maintenance Schedule

All,

My company has been running a print farm for several years. We are retiring our Lulzbot Taz printers. They have been very labor intensive and unreliable for 24/7 printing. Side note: never use Lulzbot printers for industrial scale printing. You will have a bad (and expensive) time.

We have been directed to Prusa for the quality, support, and reliability of its printers.

Does anyone have a preventative maintenance schedule for this printer?

Use: 24/7 intricate parts using PLA exclusively

I am creating a list for our operators to replace parts on a scheduled basis and to check for failure.

For example:

How often to check for bed leveling?

Are there fasteners prone to loosening?

How often should the nozzle and heat brake be replaced (using PLA ~210-220C)?

Do any sensors wear?

Anything else I am missing? What are common things to look for on a monthly basis?

RE: Preventative Maintenance Schedule

How often to check for bed leveling?

I have not checked it in 3 years. It pretty much checks itself.

Are there fasteners prone to loosening?

I check the terminals once a month on the power source. I check the other screws every 2-3 months. They rarely loosen.

How often should the nozzle and heat brake be replaced (using PLA ~210-220C)?

Unless I print abrasives, they last up to a year (or more). I have never replaced a heartbreak.

Do any sensors wear?

Thermistors will need replaced sometimes. I have had to replace them about one a year or so but I have some that are 3 years old. I clean the bed one to two times a week.

Anything else I am missing? What are common things to look for on a monthly basis?

Once every 1-3 months, I add a little lubrication to the bearings if it seems like it needs it. It increases with age.

All,

My company has been running a print farm for several years. We are retiring our Lulzbot Taz printers. They have been very labor intensive and unreliable for 24/7 printing. Side note: never use Lulzbot printers for industrial scale printing. You will have a bad (and expensive) time.

We have been directed to Prusa for the quality, support, and reliability of its printers.

Does anyone have a preventative maintenance schedule for this printer?

Use: 24/7 intricate parts using PLA exclusively

I am creating a list for our operators to replace parts on a scheduled basis and to check for failure.

For example:

How often to check for bed leveling?

Are there fasteners prone to loosening?

How often should the nozzle and heat brake be replaced (using PLA ~210-220C)?

Do any sensors wear?

Anything else I am missing? What are common things to look for on a monthly basis?

How often to check for bed leveling?

Are there fasteners prone to loosening?

How often should the nozzle and heat brake be replaced (using PLA ~210-220C)?

Do any sensors wear?

Anything else I am missing? What are common things to look for on a monthly basis?

--------------------

Chuck H

3D Printer Review Blog

RE: Preventative Maintenance Schedule

- Lubricate the smooth rods in shorter intervals, but with very little amount of grease

- DO NOT lubricate the thread of the Z-axis, as the nut is made of a self-lubricating polymer

- Lubricate the Bondtech gears with very little grease (not the groove for the filament)

- Clean the blades of the fans from dust and stringing (if you print PETG). Block the rotation of the fan if you use a vacuum cleaner, so that it does not spin with 100000 RPM 😉

RE: Preventative Maintenance Schedule

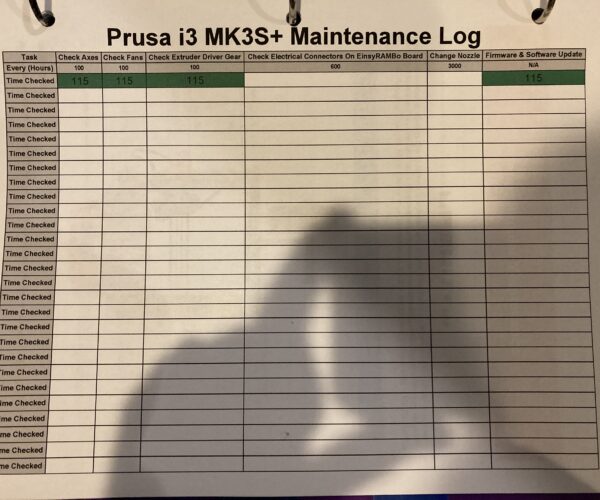

This is how we do it and it worked very well :