Nozzle-to-PINDA Z-Distance Calibration

After almost a thousand hours of reliable printing, I started getting a poor first layer, pretty much suddenly. Running first layer calibration again cause me to lower the Z re-calibrated the first layer height and wound up lowering the Z-calibration from -0.725 mm to -0.850 mm, then to -0.925 mm, then to -0.950 mm over several prints. In total, I moved the extruder a total of 225 microns lower / closer to the bed.

Not sure why I had to do this, but I suspected that somehow the Z-Distance between the Nozzle and the PINDA had changed.

I had initially measured the Nozzle-to-PINDA Z-Distance to be 0.82 mm when the Mk3 arrived on 4/2/2018. This was done with paper feeler gauges made of 24lb Staples printer paper. On-line sources ( https://printing.ucr.edu/paper_thickness.html ) quoted 24lb / 60lb offset text (uncoated) paper and 80lb gloss text coated paper at 0.004″ = 4 mil = 0.01016 cm = 0.1016 mm per sheet. I separately measured a stack of sheets with a micrometer and came up with 0.1023 mm per sheet of 24lb paper, so it seemed like a reliable thickness.

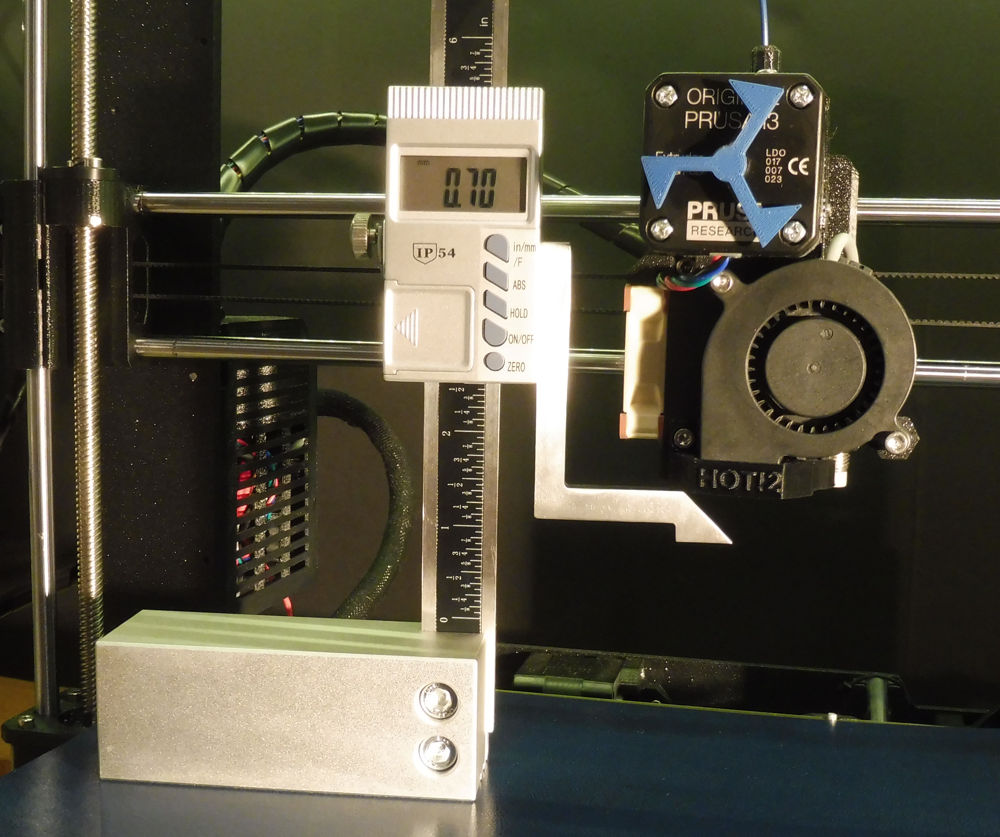

However, using paper feeler gauges to measure nozzle height seemed error-prone, so I started using a digital height gauge – specifically, an iGaging Digital Electronic Height Gauge with Magnetic Base, 6 Inch.

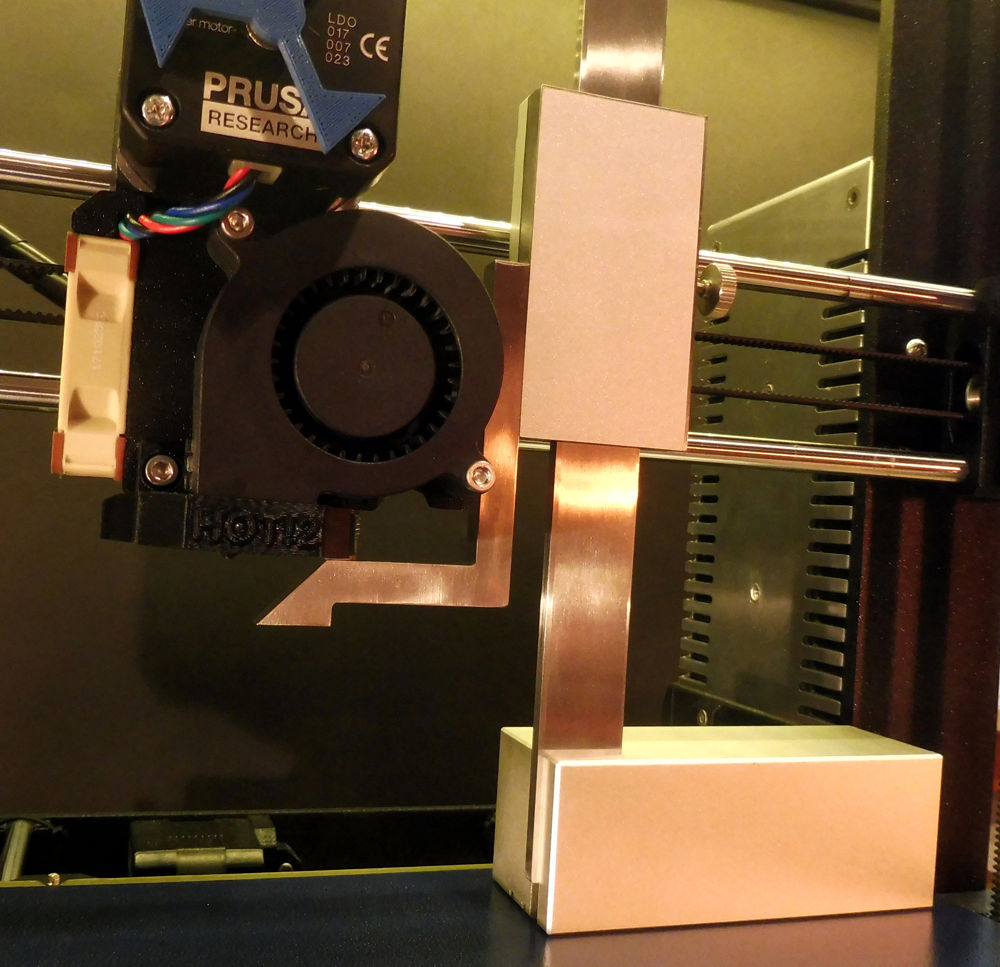

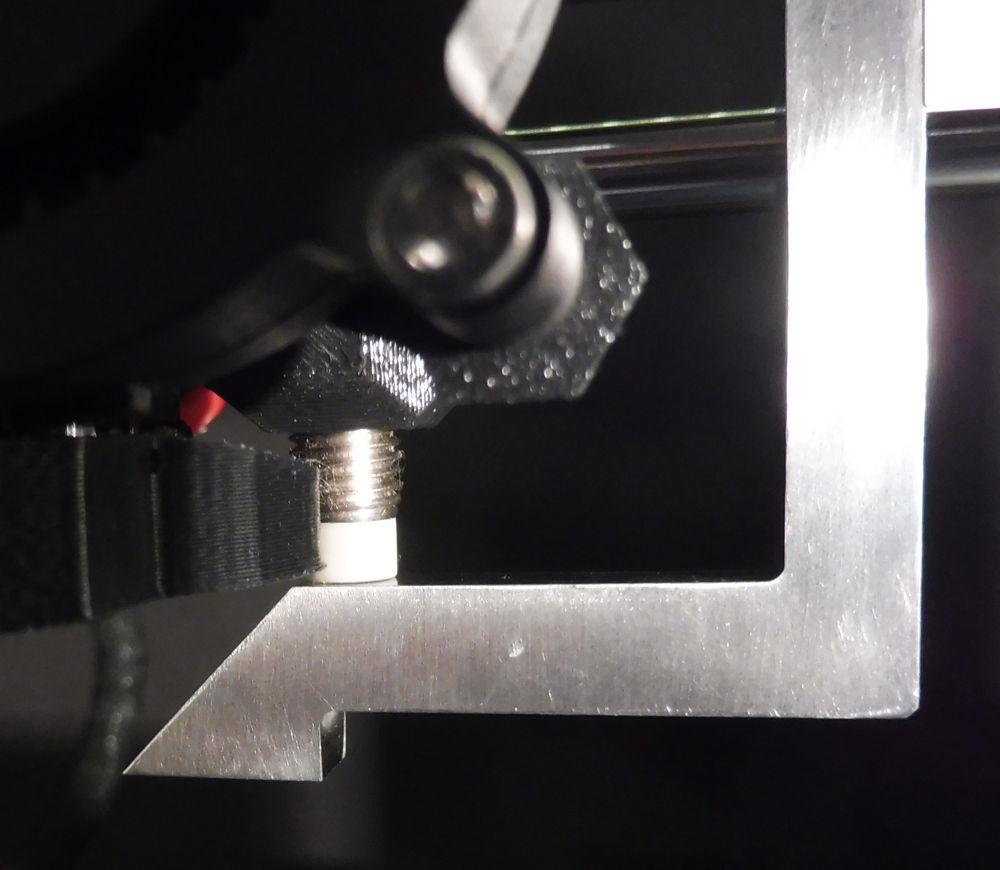

This seems to be an ideal tool for measuring Nozzle-to-PINDA Z-Distance, with some caveats:

Note that I am using the top of the horizontal measuring arm of the height gauge rather than the typical use of the bottom of the arm.

Here is a close-up of the horizontal arm raised to the level of the PINDA probe:

Re-measuring the Nozzle-to-PINDA Z-Distance yesterday gave 0.70 mm – a difference of 120 microns. This would account for the need to lower the nozzle by 120 microns, where I actually needed an adjustment of 225 microns.

How / why the PINDA got lower (or the nozzle got higher) is a mystery.

-- Clint Goss

Re: Nozzle-to-PINDA Z-Distance Calibration

Is it possible that your nozzle has worn enough to cause problems?

What have you been printing? (filament-wise)

That's "MISTER Old Fart" to you!

Re: Nozzle-to-PINDA Z-Distance Calibration

Printing with PLA and nGen (copolyester). Can't imagine anything could produce that much wear ... but I really don't know ...

-- Clint Goss

Re: Nozzle-to-PINDA Z-Distance Calibration

Your PINDA probe might be not fully secured and got loose. Happened to me once. Try to wiggle and turn the PINDA probe in all directions and check if there is any play.

0.2mm is not much but if it happened suddenly then something happened and got loose. If you don't find anything, keep an eye if current Z-height stays stable or not. In most cases you have a mechanical play somewhere.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Nozzle-to-PINDA Z-Distance Calibration

Printing with PLA and nGen (copolyester). Can't imagine anything could produce that much wear ... but I really don't know ...

Anything filled or composite (including luminous)? Filled filaments are the worst culprits, but some composites can be abrasive as well--depends on the particulars.

That's "MISTER Old Fart" to you!

Re: Nozzle-to-PINDA Z-Distance Calibration

You can also make a new "Calibrate Z" if the X-axis is tilted.

Bear MK3 with Bondtech extruder

Re: Nozzle-to-PINDA Z-Distance Calibration

I have a query in to the good folks at ColorFabb about the abrasive index of nGen and nGen Lux ...

-- Clint Goss

Re: Nozzle-to-PINDA Z-Distance Calibration

Clint, thank you for posting. I enjoyed your idea so I ordered the same device that arrived today. I was able to properly measure my first MK3 after reassembling it with the R3 parts.

This will come in handy when changing nozzles and other maintenance in the future.