New printer, 100% failure rate with silk PLA

Hello, I recently got an assembled MK3S+ with a smooth print plate after selling my End3-Pro.

I am having no success with a Polychromatic 3 colour silk PLA , and very little luck with a marble PLA. I now have countless hours of print time and every silk PLA print fails with the print breaking free. With the marble I have had a bit of success, but not much. My first print experience with the Prusa was not good as after not even an hour into my first print I learned what "heat creep" was as the silk PLA became completely stuck in the PTFE tube and I had pull my new printer apart and replace the tube.

With all different adjustments I am attempting, the print breaks free. I have noticed at times some form of warping so the nozzle is likely bumping it.

I have attempted altering the temperature for the bed, and tried running without the fan for several layers to prevent warping. Also tried slicing with and without a brim.

My default settings are 215 nozzle and 60 bed which I learned worked great for the End3-Pro, so used these as the starting point for the Prusa.

The print I have been attemping is an articulated lizard from thingyverse, trying to print this with the polychromatic as I have friends asking for them for their kids. There are times the failure happens soon after starting, and other times could be an hour into the print. I had very few failures with my previous printer using no brim.

Any suggestions are very appreciated, I am becoming beyond frustrated at this point and running out of ideas and could really use some help diagnosing.

Thanks,

Craig

RE: New printer, 100% failure rate with silk PLA

I print silk at about 10 degrees hotter than usual. However, the print breaking loose sounds more like bad adhesion, which is usually either a sheet issue (wash throughly with hot water and fragrant free dishwashing soap) or incorrect live z calibration.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: New printer, 100% failure rate with silk PLA

Thanks for the suggestions @fuchsr. I had made some z adjustments, wondering if that would help. With your suggestions I'll look at it closer and keep going to get this sorted out.

Will keep you posted.

Thanks

Craig

RE: New printer, 100% failure rate with silk PLA

Thorough bed cleaning and spot on first layer calibration should secure bed adhesion. If you still have issues, you can use build plate adhesive. Shouldn't be necessary for PLA prints but can be a solution nonetheless.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: New printer, 100% failure rate with silk PLA

Thanks for the suggestions.

After a few more prints failing I have noticed a pattern that is repeating.

There is a clicking/cracking sound that I hear at the time the print fails. Looking at what has happened it is caused when the portion of the print moves. The click/cracking sound is the print part being peeled from the bed by the nozzle, the print is not just being brushed aside it is being forced.

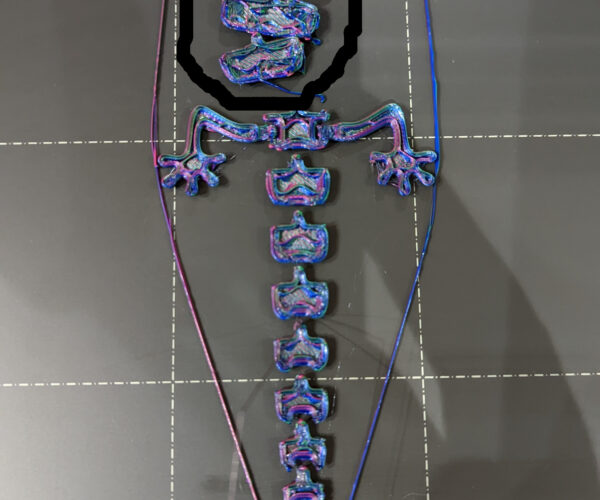

In the photo attached here, this occured at about 17% completion layer 10 of 62. You can see two peices of the print have been dislogged and aren't lined up with the rest of the print

This doesn't seem like poor adhesion? When I clean the rest of the parts from the plate they are nicely adhered to it and take a bit of force to break free.

I have also sliced this with a brim and when printing, the brim lifts in multiple spots.

Thanks

Craig

RE: New printer, 100% failure rate with silk PLA

This may sound crazy, but make sure you only have one instance of the object one the printer bed in the slicer. I’ve accidentally had two instances in the past and it did exactly what you are describing.

Look at the object viewer on the right hand side of PrusaSlicer, you can tell if there are two instances. It’s one of those dumb things I’ve done in the past, and hopefully you didn’t repeat my mistake. 😉

Mini+MK3S+XL 5 Tool

RE: New printer, 100% failure rate with silk PLA

The live z on that model isn't squished enough. You can tell just from the skirt alone. That is going to make bed adhesion low and then the parts are probably lifting/curling up as the layers contract as it moves upwards. This causes the nozzle collisions and the part detaches as again it doesn't take much force to detach as the adhesion is low.

RE: New printer, 100% failure rate with silk PLA

Update: I had some time today and have been making more tweeks to the setup.

A more aggresive z adjustment did the trick and I finally completed my first print! Thanks for everyones help, now I have a better idea of how the filament should look on the first layer and will continue to tune more.

Thanks again,

Craig