new PEI sheets with worse quality?

Hello,

I own 6 x Prusa MK3S+ and do a small batch production of PETG parts.I always print with the same material (from Extrudr), the same settings and smooth PEI sheets.For almost a year now. After I found the right settings, also absolutely no problems.

Recently I bought 3 additional PEI sheets to be a little more flexible.

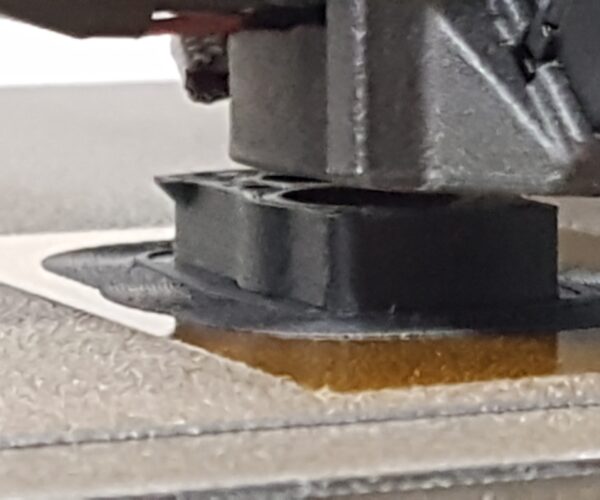

Directly at the 1st print, the surface of 2 sheets has loosened when I wanted to remove the print parts. So not these typical bubbles that disappear again, but small pieces of the surface were torn out!

When I asked PRUSA how this could be, they said:1. PETG and smooth PEI is a bad idea.2. do not clean with ISA, only with glass cleaner (why do ISA cleaning cloths come with every printer?)3. always use glue stick with PETG.4. (the best!) The same PEI sheets you can buy today have a higher adhesive strength than the ones you can buy a year ago.(great, wouldn't it be nice if customers knew that too?)!

So, maybe I am wrong but I wonder why I can print every day min. 12h with 6 printers without any problems if I have done everything wrong so far?

But ok. I no longer used ISA, but only glass cleaner = no change.I used the glue stick and it got worse.I also made a video of this:

I have now gone back to using my old PEI sheets. No more problems!

Of course I can be wrong, but to me it just looks like PRUSA (after the PEI sheets were not available for a long time) might have a new, additional supplier and the quality of the surface is just worse now than before.

RE: new PEI sheets with worse quality?

I had exactly the same problem with my brand new build sheet using PETG. My second print on the new sheet tore out a small chunk. I have never had this happen on previous sheets and I typically do not use gluestick or windex, etc. They told me the same thing, that printing PETG without gluestick or windex is a no-no. I was very careful removing my part too...

I think you may be correct and perhaps something about the product has changed or else maybe a bad batch. I have not tried using the gluestick or windex but I will. I hope it does not tear off some more! Alas, they would not warranty the sheet, even though it was just purchased.

-Ben

RE: new PEI sheets with worse quality?

Hi Ben, thanks for the reply.

By the way, Windex is just a cleaner (actually window cleaner) but does not form a protective layer on the sheet as far as I know.

I think this has nothing to do with warranty, but the product is actually not O.K. already at delivery.

PS: Unfortunately I can't reply to your PM (no rights) but. I mainly print mounts and cases for certain smarthome products.

Here is my store: shellyparts.de

RE: new PEI sheets with worse quality?

Windex is used to reduce adhesion between petg and the smooth sheet as petg grips it too well. The manual even warns about printing petg on the smooth sheet. Windex acts as a barrier. Its a common technique.

When going back to printing pla on the sheet you need to make sure its absolutely cleaned off.

RE: new PEI sheets with worse quality?

For such cases, I always use Kapton foil to protect the printing plate. It protects effectively and is not expensive.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE:

do i miss something? PETG with 210°c ?

raise the bed to 90°c and print the PETG with 230+

if you cleaned with IPA you will have hard times to get it off.

Using windex helps to pop it off on smooth sheet.

RE: new PEI sheets with worse quality?

This is the ideal temperature for the material I use.

I have tested this extensively. And the bed temperature in the original filament settings of Prusaslicer for Extrudr PETG is even only at 70C!

If I increase the bed temperature, the part will not come off better. The opposite is the case.

Please watch my video. The part goes off excellently from the bed. However, only with the old PEI sheets. Not with the new ones that I got delivered.

RE: new PEI sheets with worse quality?

the chances are that your old sheets are contaminated with finger grease or similar and have reduced adhesion capabilities, whilst your new ones are not contaminated and bond exceptionally well

some people use Windex or talcum powder to reduce adhesion in a controlled manner, when printing with PETG, or TPU, both of which normally bond exceptionally well to clean PEI!

here is a reminder I put on a reel of TPU, when smooth pei was the only option

I sprinkle talcum powder on the PEI, then rub it in with a tissue, and wipe any loose material off, then use the Build plate for either PETG or TPU prints

regards Joan

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: new PEI sheets with worse quality?

Thanks for the answer, but it does not seem very logical to me. Because the old PEI sheets were also new some time ago and the problems did not occur. In addition, I have (until last week) the sheets regularly cleaned with ISA (with the old without Sheets problems) so that I can exclude greasy fingers.

That there could be a quality problem with PRUSA or a supplier can be excluded. Why? Because it is PRUSA to we are all big fans. 🙂

RE: new PEI sheets with worse quality?

I recently ordered a new 'factory second' PEI plate and to be honest, I can't tell the difference between that and a rather new 'factory first' plate.

When I was unfamiliar with the PEI plates, I printed a large ABS object and I got impatient when it did not want to readily release and used a metal kitchen implement to remove it, along with a few pieces of the PEI coating. Yes, those PEI coatings cannot take a joke! A half hour in the refrigerator or so would have most likely released the print.

There seems to be a lot of chatter lately suggesting that the smooth plates and PETg are not a good match.

I've been doing countless PETg prints on the smooth PEI plates for some time now with excellent results.

I almost always use Layerneer for such prints, both as an adhesion booster and release agent.

PETg is a good general-purpose filament. It's not so great for very small pieces or pieces with a lot of fine detail, but for larger objects I've had excellent luck with it.

RE: new PEI sheets with worse quality?

It's the same for me.PETG so far also without problems. What surprises me is that PRUSA support has informed me in writing that the new PEI sheets now have a significantly higher adhesion than those of a year ago.

This may explain why I never had problems before but suddenly the sheet is damaged when I remove the parts.

I think only that would have to be communicated to customers. 🙁

Sorry, I do not read the online manual every time I buy a product that I have been using for a year.

Probably my mistake. At least that's what Prusa says.

I recently ordered a new 'factory second' PEI plate and to be honest, I can't tell the difference between that and a rather new 'factory first' plate.

When I was unfamiliar with the PEI plates, I printed a large ABS object and I got impatient when it did not want to readily release and used a metal kitchen implement to remove it, along with a few pieces of the PEI coating. Yes, those PEI coatings cannot take a joke! A half hour in the refrigerator or so would have most likely released the print.

There seems to be a lot of chatter lately suggesting that the smooth plates and PETg are not a good match.

I've been doing countless PETg prints on the smooth PEI plates for some time now with excellent results.

I almost always use Layerneer for such prints, both as an adhesion booster and release agent.

PETg is a good general-purpose filament. It's not so great for very small pieces or pieces with a lot of fine detail, but for larger objects I've had excellent luck with it.

RE: new PEI sheets with worse quality?

Oh, one thing as a warning, if you buy one of those Fysetc (Fystec?) sheets, it's coated on only one side! Other side is bare metal!

RE: new PEI sheets with worse quality?

I also found that PETG stuck badly to my smooth PEI. I didn’t find the Windex worked as well as the glue stick.. There is also a video by Maker Muse that shows how to use only a few swipes of glue stick and then, with a damp rag of something else (alcohol/windex?), wash the surface to create a really smooth and thin layer. I’ll only use glue stick now on a smooth PEI. But I recently got a rough PEI and it is absolutely super for PETG. Use PETG on it is even more reliable than using PLA on my smooth. However, you need to scrub the rough PEI pretty well for the first few times to get off any manufacturing contamination; and set the correct Z and then remember to change the setting on the display. But I really like the rough PEI.

RE:

I print PETG on my smooth sheets all the time. I clean the sheet with IPA. Then, spritz some windex (glass cleaner on it.) I spread windex around on sheet until it is full covered with a thin coat. Heat up the bed and let the windex evaporate. Once evaporated, start the PETG print. Print pops right off with a flex of the build plate.

Now, when I go back to PLA, I Scrub the build plate/PEI sheets with hot water and soapy dawn dish soap. Thoroughly dry and then wipe down with IPA.