MK3 vs MK2s profile speeds

First off I want to mention that this is not a gripe, but rather an observation and somewhat of a question. I have been observing the Slic3r MK3 profiles slowing down revision over revision while the MK2 profiles have remained consistently fast since the last firmware and introduction of linear advance. So I was slicing the identical object with slic3r 140.1 and noticed that under identical profiles, the MK2 estimated a time of about 20-30% less time to complete. This did prove out in the print job as well. I find this a bit confusing due to the addition of the rigid frame, enhanced drivers, and extruder bits. One would think that the speeds would be the other way around. I will state that they both print just fine for my purposes and I am hopeful that the team continues to drive any of the remaining extrusion gremlins out of the system. Perhaps this is the reason for the change, however, I would think that someone new to PRUSA or 3d printing would be a bit baffled watching the MK2S fly along while the MK3 tends to meander a bit.

Again I want to point out that I merely am interested in understanding the logic, and not complaining. I love all of my Prusa printers which now is a total of seven. 3 MK2Ss and 4 MK3s. One additional thought came to mind in this process regarding the MK2.5. Will it operate on the MK3 profile or more similar to the MK2s? If anyone has an idea, please let m know.

Re: MK3 vs MK2s profile speeds

Note: This question has gone for more than a month without an answer.

I have been observing the Slic3r MK3 profiles slowing down revision over revision while the MK2 profiles have remained consistently fast since the last firmware and introduction of linear advance. So I was slicing the identical object with slic3r 140.1 and noticed that under identical profiles, the MK2 estimated a time of about 20-30% less time to complete. This did prove out in the print job as well. I find this a bit confusing due to the addition of the rigid frame, enhanced drivers, and extruder bits. One would think that the speeds would be the other way around.

I want to second these observations. I have a Mk2.5 (built from kit January 2017, fully upgraded as of July 2018) and a Mk3 (built from Kit in January 2018). I've been running them fairly hard since early July (250 hours for the Mk2.5, 300 hours for the Mk3) and typically printing the same objects on each printer, with the same materials (PETG). I'm using the latest released versions of firmware (3.3.1) and Slic3rPE (1.40.1) on both printers. I've been slicing my prints at 0.200mm using the standard profiles, with exactly the same tweaks for each printer (fewer horizontal layers, 5% rectilinear infill, output filename format). For the Mk2.5, I'm inheriting from the 0.20mm 100mms Linear Advance profile; for the Mk3, I'm inheriting from the 0.20mm FAST MK3 profile.

With these settings, the Mk2.5 is as much as 20% faster than the Mk3 for my prints (example models here: https://www.thingiverse.com/thing:3050081 ). I would have expected the Mk3 to be faster than the Mk2.

The difference in the profiles would be:

0.20mm 100mms Linear Advance; estimated printing time = 52m 28s

; start_gcode = M115 U3.1.0 ; tell printer latest fw version\nM201 X9000 Y9000 Z500 E10000 ; sets maximum accelerations, mm/sec^2\nM203 X500 Y500 Z12 E120 ; sets maximum feedrates, mm/sec\nM204 S1500 T1500 ; sets acceleration (S) and retract acceleration (T)\nM205 X10 Y10 Z0.2 E2.5 ; sets the jerk limits, mm/sec\nM205 S0 T0 ; sets the minimum extruding and travel feed rate, mm/sec\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG1 Y-3.0 F1000.0 ; go outside print area\nG92 E0.0\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line\nG92 E0.0

; end_gcode = G4 ; wait\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG1 X0 Y200; home X axis\nM84 ; disable motors

; infill_acceleration = 2000

; max_print_height = 200

; max_print_speed = 150

; retract_lift_below = 199

; support_material_speed = 60

; bridge_speed = 20

; external_perimeter_speed = 50

; infill_speed = 100

; perimeter_speed = 60

; small_perimeter_speed = 30

; solid_infill_speed = 100

; top_solid_infill_speed = 70

0.20mm FAST MK3; estimated printing time = 1h 3m 6s

; start_gcode = M115 U3.1.1-RC5 ; tell printer latest fw version\nM201 X1000 Y1000 Z200 E5000 ; sets maximum accelerations, mm/sec^2\nM203 X200 Y200 Z12 E120 ; sets maximum feedrates, mm/sec\nM204 S1250 T1250 ; sets acceleration (S) and retract acceleration (T)\nM205 X10 Y10 Z0.4 E2.5 ; sets the jerk limits, mm/sec\nM205 S0 T0 ; sets the minimum extruding and travel feed rate, mm/sec\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG81 ; output bed leveling results\nG1 Y-3.0 F1000.0 ; go outside print area\nG92 E0.0\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line\nG92 E0.0\nM221 S{if layer_height==0.05}100{else}95{endif}

; end_gcode = G4 ; wait\nM221 S100\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG1 X0 Y200; home X axis\nM84 ; disable motors

; infill_acceleration = 1500

; max_print_height = 210

; max_print_speed = 170

; retract_lift_below = 209

; support_material_speed = 50

; bridge_speed = 30

; external_perimeter_speed = 35

; infill_speed = 170

; perimeter_speed = 45

; small_perimeter_speed = 25

; solid_infill_speed = 170

; top_solid_infill_speed = 50

Obviously, the MK3 profile is focused on infill speed not perimeter speed, and the models I'm printing all heavily weighted towards perimeters, not infill due to using lots of thin walls. What I want to know is why the Mk3 profiles are set so much slower than the Mk2.5 when the Mk3 has better hardware than the Mk2.5?

- Craig -

I solve problems, usually with computers ...

Re: MK3 vs MK2s profile speeds

I assume the reason is the "extrusion issue". Because so many people started to complain about not so good looking prints (with default settings) PR adjusted those.

The MK3 hardware itself is not really better in terms of print quality. It just allows you to print faster. Because everything else is still the same (heavy direct extruder head, same rods, same moving concept), the print speed decrease the print quality.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: MK3 vs MK2s profile speeds

I assume the reason is the "extrusion issue". Because so many people started to complain about not so good looking prints (with default settings) PR adjusted those.

The MK3 hardware itself is not really better in terms of print quality. It just allows you to print faster. Because everything else is still the same (heavy direct extruder head, same rods, same moving concept), the print speed decrease the print quality.

Well, given that for my purposes the print quality from my Mk2.5 is as good as the print quality from my Mk3, I'd like some profiles for the Mk3 that are at least as fast as the Mk 2.5 with linear advance. Again, right now, the Mk3 is 20% slower than the Mk2.5 for the same parts.

For reference, my definition of a high quality print:

The Mk2.5 does that, and the Mk3 used used to do that faster than the Mk2.5.

I realize that there are some people loudly freaking out about the perceived imperfections of their prints, but that doesn't mean that the rest of us should be given short shrift on speed.

Hint: it's OK to release more than one profile per layer height, since it's done for the Mk2 / Mk2.5 anyways.

- Craig -

I solve problems, usually with computers ...

Re: MK3 vs MK2s profile speeds

I realize that there are some people loudly freaking out about the perceived imperfections of their prints, but that doesn't mean that the rest of us should be given short shrift on speed.

Just update the configuration to your needs and print faster especially you already know why it's slower. Nobody holds you down on that.

The default PR profile is not a holy grail for everybody. Actually I'm adjusting it all the time depending on the model I print (yes, speed as-well).

I only gave you an idea why the default profile was changed in this direction. The "extrusion issue" got pretty famous. Almost every 3D printing Youtuber mentioned that. Maybe I'm wrong and it was completely different reason.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: MK3 vs MK2s profile speeds

I've slowly realized that speeds relative to 3D printing are largely illusive. Linear speed is important if you are printing single, long features. The equivalent of the 1/4 mile drag strip. Otherwise, a lot of other factors come into play. What really matters is how much filament you can lay down in a given period of time. Layer height, extrusion width, speed, acceleration and jerk all figure into the actual time required to print a given amount of material. I get a lot more benefit out of printing using "slower" linear speeds with a larger nozzle that eliminates the need for an extra perimeter or two. My extruder may move slower, but my print will finish sooner. Before I'd worry too much about "advertised" 20% difference in speeds, try a timed benchmark and see what the differences really are. For smaller parts, it may not matter at all.

[...] I'd like some profiles for the Mk3 that are at least as fast as the Mk 2.5 with linear advance. Again, right now, the Mk3 is 20% slower than the Mk2.5 for the same parts.

I look at it this way: If I'm printing detail parts, I'm likely to be using a 0.25mm nozzle and be more concerned about details, so expect to print slower. If I'm printing big functional parts, I'll reduce times significantly by using thicker, wider extrusions with a larger nozzle, and going slower is going to provide better layer adhesion. Factor in many filaments actually printing poorly at "high" speeds (most are < 70mm/s, higher speeds up to 200mm/s are advertised as speciality materials) and linear speed really isn't as important as it might sound.

Given all that, with higher acceleration and jerk settings, a Mk2.5 may well print faster if using the same materials and the same nozzle to print the same model, but it might not be all that much faster. I think it takes 15mm to come up to full speed using typical acceleration rates, so any length shorter than that will never hit your set speed. The extruder will spend typical spans accelerating and decelerating. In any case, you're using the E3D V6 extruder. You're only going to print as quickly as it can process material. With small nozzle sizes, you may get higher speeds. With a 0.40mm nozzle and 0.20mm layer heights, you're already pushing the limits at 120mm/s. The figurative speedometer on your Mk2.5 may read 140MPH, but you might have problems well before hitting that speed. (Replace with the volume knob being labeled 11 if you prefer.)

I think Prusa has had to decide on a limited number of supported configurations that they'll work with. If you are having problems, but can print using a conservative profile, they know it's likely slicer settings to blame, not hardware. They certainly don't stop you from adjusting settings to your heart's desire. You're also free to use other slicer software if it provides other features you're after. The presets just give you a known-good starting point. You can always increase those same settings for the Mk3 -- no reason not to have "fast draft" and "slow quality" settings -- and compare the difference in finish. If you're happy with the results, all is well.

Every car I've driven had a manual that provided all sorts of guidance on how to use turn signals, brake, accelerate and maintain it. That never stopped me from ignoring it when I felt the urge to go a bit faster. Guidelines are just that. They're changeable for a reason.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: MK3 vs MK2s profile speeds

[...] I'd like some profiles for the Mk3 that are at least as fast as the Mk 2.5 with linear advance. Again, right now, the Mk3 is 20% slower than the Mk2.5 for the same parts.

I think Prusa has had to decide on a limited number of supported configurations that they'll work with. If you are having problems, but can print using a conservative profile, they know it's likely slicer settings to blame, not hardware. They certainly don't stop you from adjusting settings to your heart's desire. You're also free to use other slicer software if it provides other features you're after. The presets just give you a known-good starting point. You can always increase those same settings for the Mk3 -- no reason not to have "fast draft" and "slow quality" settings -- and compare the difference in finish. If you're happy with the results, all is well.

Yes, the settings are changeable, if you're of a mind to change them and have the experience to do so without breaking, er, exceeding the capabilities of the printer.

Prusa Research has two types of customers now: hobbyists who want to tune their printer (eg: kit buyers) and users who want to print things without having to worry about the details of slicing profiles (eg: assembled printer buyers). I bought the kit(s), and am largely OK with tuning profiles. My comments are really reflective of the other type of user -- the one who isn't interested in tuning their printer; they just want it to run acceptably out of the box. That type of user is going to be disappointed if they are comparing the Mk2 with the Mk3, because their perception is going to be that for the same model, sliced with similar profiles, the Mk2 is much faster than the Mk3.

Me, I'm just disappointed that the stock profiles that Prusa Research ships for their flagship printer have become increasingly slower from one release to another.

I solve problems, usually with computers ...

Re: MK3 vs MK2s profile speeds

[...]Me, I'm just disappointed that the stock profiles that Prusa Research ships for their flagship printer have become increasingly slower from one release to another.

Well, it's interesting to be sure. I'm not actually disappointed. Prusa has gone all-in on Slic3r and it gets more powerful every day. They were heading in the direction of the "idiot light" style interface with PrusaControl, but instead seem to have shifted towards improving the "power user" tool both in terms of usability (the PC GUI being ported) and increased hardware settings and profile options.

A lot of the settings that were hidden away in Slic3r (and still are in many slicers) are now "1st class citizens". Acceleration and jerk settings are now directly configurable instead in the user interface instead of set in often-unseen gcode. I don't have to remember to edit custom gcode for every profile now. At some point, we may wind up with the ability to tweak settings per-model or per-layer. Adaptive layers heights are interesting. What might happen if the slicer can make tweaks to acceleration and jerk on-the-fly under control of configurable parameters?

I think that providing accurate parameters is more important than "better" parameters. Slic3r's time estimates are improving largely because they are at least loosely linked to reality, and that includes realistic settings. I know it was way off in earlier releases. I'd be curious to know how the Mk3 estimates compare to the Mk2 estimates in relation to actual print times. Are the "faster" presets meaningful, or just racing stripes? I recall earlier presets showing 9000mm/s acceleration. Was that an actual capability, or just a Marlin default?

I also am excited that Prusa has gone all-in on the volumetric approach to slicing, rather than dumbing things down to "speeds". I'm more confident that the presets the slicer provides are accurate and take everything (linear speed, extrusion width, layer height, acceleration and jerk) into account. If my changes in the interface actually relate to the slicing calcs and time estimates relate to reality, I'll be happy. I don't view it as the printer somehow getting slower (it didn't) so much as the software tuned to the actual hardware. I think the business has suffered overall with slicers and hardware too often not being more closely linked. I see a lot of knob-twiddling tips and posts that don't reflect reality, or don't actually do what the poster seems to think. Adjusting acceleration that starts at 9000mm/s is going to take a while before it makes any sort of difference in a print.

If they focus now on refining presets that work well for 90% of the cases, they'll be able to work on separate performance and quality presets in the future. Without that step, they'd be sure to disappoint one group or the other. Prusa's initial presets were way too aggressive for many users. Better to issue a stable set that works for most, then provide meaningful tweaks tuned to the hardware.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: MK3 vs MK2s profile speeds

... My comments are really reflective of the other type of user -- the one who isn't interested in tuning their printer; they just want it to run acceptably out of the box. That type of user is going to be disappointed if they are comparing the Mk2 with the Mk3, because their perception is going to be that for the same model, sliced with similar profiles, the Mk2 is much faster than the Mk3...

It's not about tuning a printer. Setting the slicer settings right now is still a must. You can be lucky and succeed printing only simple models without any special requirements on the parts. Maybe we will get there in the future where the algorithms will determine (near) perfect settings for the printing model. But at the moment we are far away from there. Current printing profiles are just a starting point, so you will get most likely something printed.

I'm pretty sure it will change. PR is going already that route to make the "out-of-box" user more comfortable in Sli3er. The default configurations will change over time and it will get more easier to use. Currently they still building a base for everything and trying to make it stable. Pushing and changing official profiles will happen afterwards. It's kind of refining step.

BTW: I don't believe there is such a user out there who owns MK2S plus MK3, only rely on the default Sli3er settings and only comparing the speed difference instead. ;-). Such a user is usually happy about the successful print which looks decent.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: MK3 vs MK2s profile speeds

I have been 3D printing for many years and can setup/tweak profiles, but it takes time and effort...

But there should be an easier way to adjust the slicing parameters between fast rough and fine finish setup.

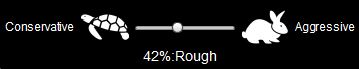

Instead of a bunch of profiles for each layer height, I would suggest only two profiles, a fine finish and a fast rough profile and a GUI slider like this:

The slider will, on the fly, generate a profile in between the the two extremes by interpolating the parameters.

This way I only have to adjust/tune the two extreme profiles and have an easy way to change the setting for a model or when experimenting.

The extreme profiles will be more stable and easier to manage as they depend mostly on the printers mechanical capabilities.

For beginners this is also way easier to understand than fast/normal/optimum/adaptive...

Have a look at my models on Printables.com 😉

RE: MK3 vs MK2s profile speeds

I know I am years late to this chat but wanted to thank every contributor for their useful inputs, esp. big thanks to DevDoc and Area51.

Recently I revamped an old MK2 as I needed extra printing capacity and this was the cheapest/fastest/easiest way to achieve that. I am also running MK3S+ alongside the MK2 and observed EXACTLY the same speed phenomenon - and I also got confused, assuming MK3S+ had to be faster than MK2 :-)))

The reason I am contributing to this thread is that I wanted to dust off the brilliant idea of Area51 about the two profiles, slow and fast, and a slider in between those two extreme settings.

I know I can always insert custom gcodes, etc... to get faster speeds but this would make the whole process so much easier and intuitive to general public/users. And for more advanced users the print speed up process would become a way lot faster procedure.

There are many articles and blogs out there about setting higher print speeds with all the theories of volumetric speeds, nozzle diameters, accelerations, etc., etc., etc. but the truth is that setting a well balanced speed print profile is no easy task at all. Esp. if you really want get most out of your printer. And there are situations when simple cranking up the dial wheel on the printer or adding a custom gcode line is not sufficiently good solution.

That is why I do not want the "slider idea"get forgotten. It deserves developer's attention!