Re: MK3 extruder randomly skipping

When did you switch over to PETG? I've re-read through this entire thread, and you've described using PLA until now. PETG is going to have very different requirements in terms of cooling, among other things. For PETG, you might back off the Live-Z adjustment a bit (0.02mm or so) and reduce cooling for better layer adhesion, at least on the lower layers. PETG generally likes heat. Your nozzle doesn't seem to be blocked. If you're using the Slic3rPE Prusa PETG profile, it should slow down the volumetric rate. If you're cooling PETG the same way you'd blast PLA, that could definitely be an issue. Extruder skips are usually accompanied by kicks and clicks. Are you getting those with both PLA and PETG, or one or the other?

[...] the whole point of this thread it to showcase an imminent problem that doesn't go away with firmware updates, extruder body replacements nor blasting cold air at the hotend and extruder motor.

I hope you're not getting frustrated at suggestions. You've had Prusa printers before, so you're obviously not new to all this. Looking at most of the extruder problem reports, issues tend to be with PLA and not PETG. I am surprised you're getting issues with both. Have you tried the same prints with the upgrade Mk2s?

If you'd care to share an STL or gcode sample that's causing problems, we can try them out to see if we get similar issues on different printers in different weather conditions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

When did you switch over to PETG? I've re-read through this entire thread, and you've described using PLA until now. PETG is going to have very different requirements in terms of cooling, among other things. For PETG, you might back off the Live-Z adjustment a bit (0.02mm or so) and reduce cooling for better layer adhesion, at least on the lower layers. PETG generally likes heat. Your nozzle doesn't seem to be blocked. If you're using the Slic3rPE Prusa PETG profile, it should slow down the volumetric rate. If you're cooling PETG the same way you'd blast PLA, that could definitely be an issue. Extruder skips are usually accompanied by kicks and clicks. Are you getting those with both PLA and PETG, or one or the other?

I've been printing with PETG on and off, not just PLA exclusively. Full Spannerhands' MK6 spool system and the R3 body were reprinted in PETG just a week ago. I've gone back to PETG after swapping the R3 extruder body because people keep saying they have success with it whereas PLA softens up and clogs. From the results I'm getting with PETG now, either R3 is no good for PETG or something else is at play here... frankly, I'm very annoyed with the whole situation having spent 800 EUR and having to go back to my MK2S for nearly everything else.

I hope you're not getting frustrated at suggestions. You've had Prusa printers before, so you're obviously not new to all this. Looking at most of the extruder problem reports, issues tend to be with PLA and not PETG. I am surprised you're getting issues with both. Have you tried the same prints with the upgrade Mk2s?

No no, I do appreciate the input and the intention to help, rest assured. I did print the same things (from the same gcode in fact) on my MK2S in exactly the same conditions and using the same filament. The result is below. It's not the cleanest print, but it's expected when you throw at it a gcode that was meant for MK3.

If you'd care to share an STL or gcode sample that's causing problems, we can try them out to see if we get similar issues on different printers in different weather conditions.

I gave the gcode another try just now and .. it didn't go well. You can find it attached, see how it prints for you or anyone else who is willing to give it a shot.

Re: MK3 extruder randomly skipping

[...] I gave the gcode another try just now and .. it didn't go well. You can find it attached, see how it prints for you or anyone else who is willing to give it a shot.

I just downloaded the gcode. I'm afraid I only have data points to add, no helpful revelations. I prepared as follows:

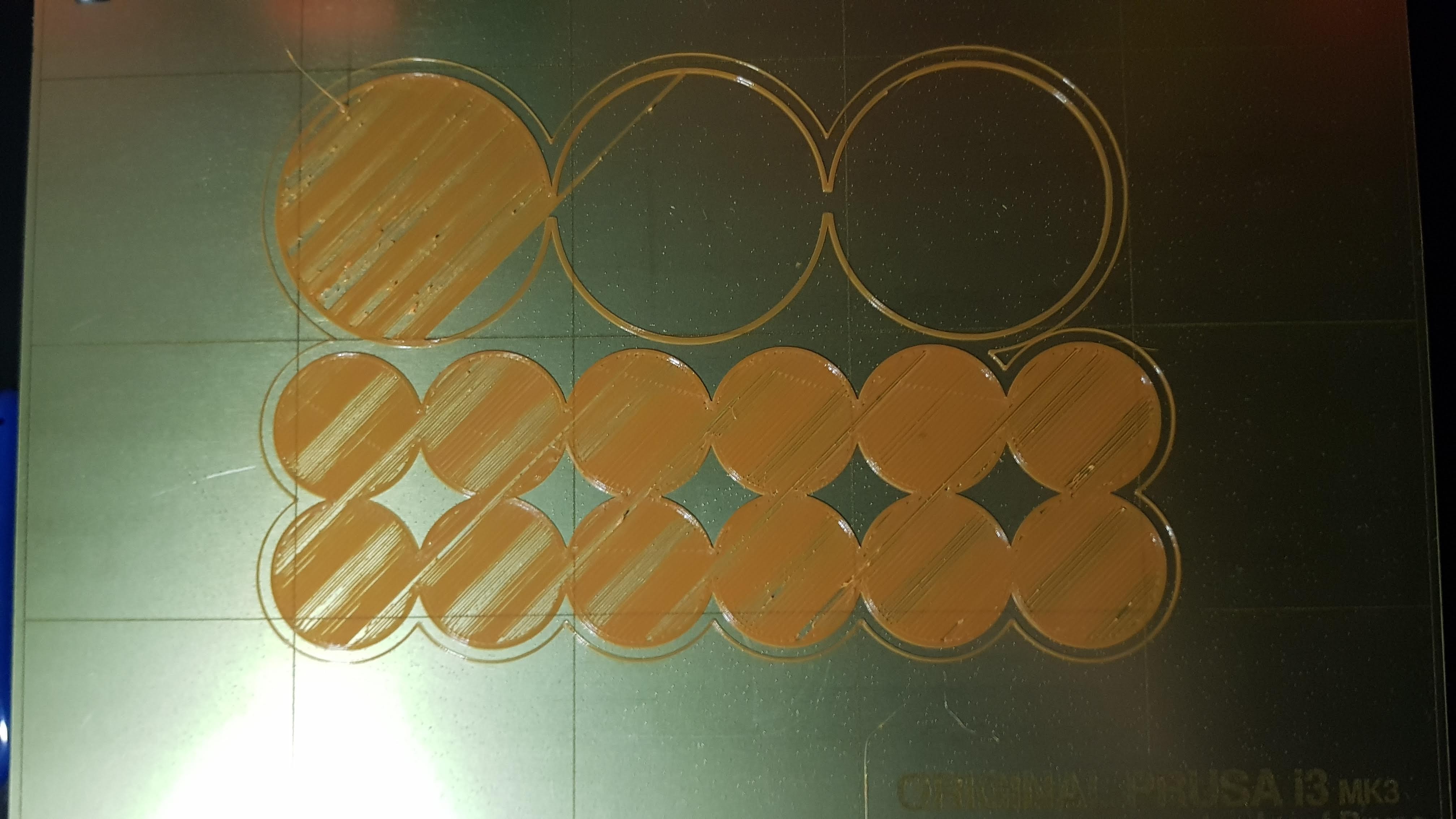

I'm printing with an ambient room temp of 74F/23.5C. I then just selected your gcode from SD card an let it print. The skirt went down without issue:

The 1st layer looks good with maybe just a bit of over-extrusion:

I did back my Live-Z 0.018mm (0.585-0.567) as I usually do for PETG, but nothing more hardware-wise. I'm letting a couple of layers finish, but it looks clean so far. There's a bit of marring that might be fixable by tweaking Z-Hop, but nothing wrong with the gcode that would cause what you're seeing in your last pics:

I did not get any extruder bucks or clicks through 2 layers.

This does confirm it's hardware or environmental. I'll re-read this thread, but it sounds like you can push filament through without issue. You seem comfortable with your 1st layer. You've tested the filament feed.

A bit basic, but can you complete a complex 1st layer like this one successfully?

I'd focus on:

Your last PETG pics do seem to show something different than your earlier PLA pics. That same PETG printed OK on your Mk2, so it must be in decent shape. I don't recall seeing any details on your nozzle in this discussion. Is it a standard E3D brass 0.40mm nozzle?

A bit of head-scratching at this point. I'd stick to either chasing the PETG or PLA issues. Can you print any older print gcode OK at this point? I'd expect not.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

I just downloaded the gcode. I'm afraid I only have data points to add, no helpful revelations.

...

I'm printing with an ambient room temp of 74F/23.5C.

...

I did back my Live-Z 0.018mm (0.585-0.567) as I usually do for PETG, but nothing more hardware-wise. I'm letting a couple of layers finish, but it looks clean so far. There's a bit of marring that might be fixable by tweaking Z-Hop, but nothing wrong with the gcode that would cause what you're seeing in your last pics. I did not get any extruder bucks or clicks through 2 layers.

This does confirm it's hardware or environmental.

I appreciate you having gone in-depth with this one!

These first couple layers look grand, the extrusion width is indeed a smidge too much though. The ambient temp here is 32C, so that's quite a difference, although not a drastic one for PETG, which really softens up at some 65-70C. I generally despise Z-hop for PET if the model is mostly comprised of perimeters. And given the scarring is inside the holders here, that's not really a concern.

A bit basic, but can you complete a complex 1st layer like this one successfully?

I'd focus on:

Your last PETG pics do seem to show something different than your earlier PLA pics. That same PETG printed OK on your Mk2, so it must be in decent shape. I don't recall seeing any details on your nozzle in this discussion. Is it a standard E3D brass 0.40mm nozzle?

This was a great hint. After fitting the R3, I'd watched the latest video from Prusa Research which ended up deceiving me by saying to tighten the idler screws just enough for the gears to start grabbing on the filament. Being completely oblivious to the fact PETG is far more slippery than PLA or ABS, I've had mine barely grabbing and hence resulting in failure to feed through after initial retract on the part of the filament that was getting barely chipped by bondetch gears.

After fiddling with the tension, the test pattern printed fine on the first try. And yes, I'm just using a standard 0.4mm nozzle on the MK3.

A bit of head-scratching at this point. I'd stick to either chasing the PETG or PLA issues. Can you print any older print gcode OK at this point? I'd expect not.

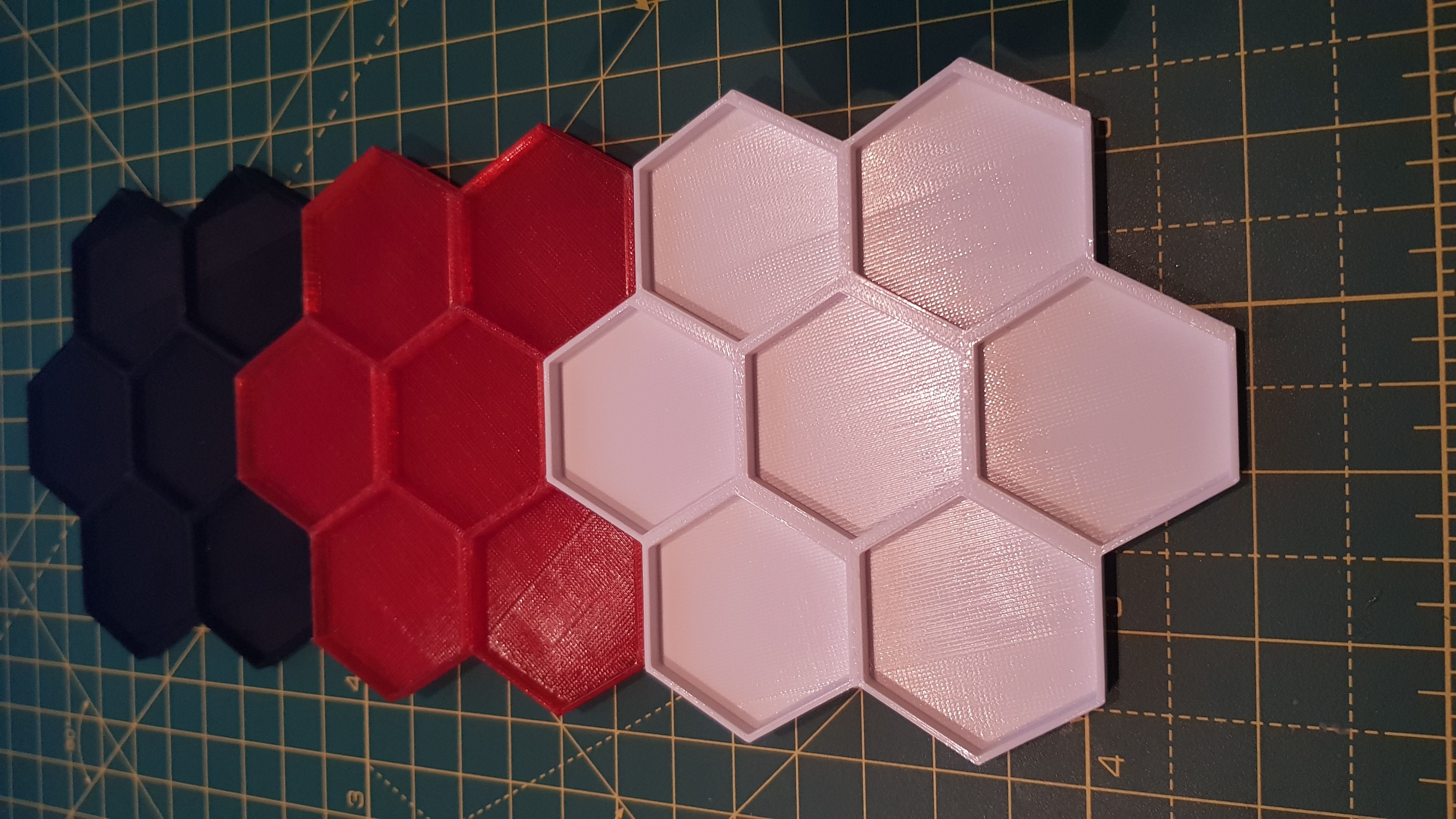

I went back to a nesspresso cup holders that I'd printed a week ago and 3 of them printed just fine in 3 different brands of PETG. So all is well for now and I have the Vallejo holders printing without any hiccups as I type this *touches wood*

Appreciate the help with getting the PETG back in business, I shall try and revisit PLA so! ❗

Re: MK3 extruder randomly skipping

[...] Appreciate the help with getting the PETG back in business, I shall try and revisit PLA so! ❗

Glad you're back in business. The great news is that it looks like your hardware is functional, so everything else should be adjustments.

Good point about those scars being on the inside. I do enable Only retract when crossing perimeters. Retraction seems to be a major cause of heat, and I'm trying to minimize it where I can without causing finish issues. PJR brought up a good point about Linear Advance supposed to reduce a lot of the retraction concerns. I'm going to play around with that approach some.

Have fun with it!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

I did print the R3 Parts in PETG after I got my spool of black PETG from Prusa. Then I changed the parts on my printer and started the calibration wizard.

After 3 attempts I gave up on the first Layer calibration with PLA. I just did not come out the way I was used to it. Even the ambient temperature here dropped meanwhile from nearly 40C to 28-30C, the PLA seems to be too soft when printing it.

So I switched back to PETG and did a live z adjustment. Now I seem to have a problem with my z height over the build plate. While on one corner the first layer is much to thin, on the other corner the distance from the nozzle to the build plate is too much so that the prints to stick to the build plate(when printing multiple parts, one by one). I would assume that the leveling should compensate for that.

Just by eye and calibrating the z axis several times I could not find the problem. Even checked that the heatbed and the back surface of the build plate is clean.

I am not sure what that problem with the z axis is now. But until this is fixed I cannot really say if the R3 did improve anything for my yet.

Re: MK3 extruder randomly skipping

I'm experiencing this problem a ton and can't seem to make any headway as documented in a separate thread ( https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/clicking-extruder-followed-by-a-jam-across-differe-t22770.html#p97231 ) .

I installed the R3 parts over the weekend and have found that the issue persists so it's not a panacea for this heat creep issue.

Re: MK3 extruder randomly skipping

After days of printing with PETG I tried PLA agin. I used an old large model just 15% infill and it came out perfectly. I printed it again as the first print was at might and temperature dropped below 20C, so I tried at daytime with around 24C. Also worked well and looked very good.

Then I tried an old gcode file with small objects and after the 3rd object the filament was stuck again. 🙁

So the new R3 parts did not change anything and as the ambient temperature dropped from the unusual 40C back to 24C at daytime this could not be the root cause as well.

The root cause seems to be the retraction and the filament shows the bellows front he pull and lush form the retractions. What annoys me is that those gcode files worked in the past with the same filament. Only thing that changed is the firmware of the MK3.

Re: MK3 extruder randomly skipping

After days of printing with PETG I tried PLA agin. I used an old large model just 15% infill and it came out perfectly. I printed it again as the first print was at might and temperature dropped below 20C, so I tried at daytime with around 24C. Also worked well and looked very good.

Then I tried an old gcode file with small objects and after the 3rd object the filament was stuck again. 🙁

If you care to share the gcode that fails, I can take a look at it. Provide some notes on where it fails. A snapshot of your slicer settings would also be helpful.

[...] The root cause seems to be the retraction and the filament shows the bellows front he pull and lush form the retractions. What annoys me is that those gcode files worked in the past with the same filament. Only thing that changed is the firmware of the MK3.

Did you do a reset after the firmware update? Settings can definitely be a bit different after an update. I'd suggest re-slicing that same part using recent Slic3rPE updates and trying it again. Rapid retractions can definitely cause problems.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

I did some more testing and now I figured out some settings that work. But I can only print in 0.2mm layer height and fast, on th edge to the point where it is so fast that the Layers do not bond together and I get a rought surface.

But printing in 0.15mm Layer height always blocks the heatbrake, even with retraction disabled.

RE: MK3 extruder randomly skipping

The most common cause of under extrusion is printing at temperatures that are either too high or too low for your material. If a material is being printed at too low a temperature, it does not melt evenly upsers