Re: MK3 extruder randomly skipping

Hi,

same problem with my MK3 here. I printed for months the same G-Code files with the same filament without any issues. Then I experienced a lot of failed prints when the filament sensor did detect no movement on the filament, but sometimes also just the printer printing in the air.

I tried to put more tension on the extruder gears, which just lead to the problem that the filament was pouring out above the heat block and dripping on my print randomly. I also noticed the Extruder motor getting extremely hot.

And just like all others here described the problem is only with slow prints, the top surface and if you have some details like text on it. So slow and lots of retraction.

I started to replace the nozzle as I printed Nylon and PETG as well and I thought that might be some residue stuck in the nozzle. As this did not help I replaced the heat brake as well. No success either. Next I purchased a complete hot end from Prusa and replaced mine with it. No change.

As I was getting real desperate I ordered a new extruder motor and new bondtech gears and replaced them as well, so everything in the extruder and hot end was basically new, but the issue was still there.

Then I found a post yesterday that described the same problem, and it was solved by applying thermal compound on the heat brake. I got some expensive thermal compound and applied it to the upper part of the heat brake that contact the heat sink. No success either.

I experimented with different temperatures. I printed those objects for months with 210C, even the vendor recommends 215C. I have tried everything from 190C to 225C in 5C steps, not much big of a difference.

But the lead to a temperature problem let me think of putting a Dyson bladeless blower next to the printer and focused it on the hot end. Except that the printer now had to turn on the heaters more often there was not really a big change.

So I tried a hairdryer set to blow cold air and posted it directly to the air intake of the extruder body. And nope, I did not change anything.

So I started a little more research on the issue and found that the nozzle itself is never clogged, but the filament is jammed. Usually I does not take a lot of force to push the filament by hand. But when the problem occurs I cannot push it with all the force I can apply to it.

Then I looked more on the unloaded filament and noticed the distance between the marks from the bod tech gears and the blob is always the same. It is around 65mm, which is exactly at the point in the heat break that is between the heat sink and the heater block.

Also the blob looks always the same, looks like the filament was folded by the retracts and increased in diameter. Then it seems to be to thick to get pushed further.

I have also made a cold pull at 80C and you can see that there is a distance between the blob and the filament end with the nozzle shape. It is stretched from th pull, but it show that the problem is some mm above the nozzle.

My Problem is not solved and already spend 200€ on spare parts that did not fix anything. Not sure what to do. As said in the beginning I printed the same parts with exactly the same G-Code files and the same PLA filament for months without any issue. Besides that it is summer and the temperature is now around 30C nothing really changed. But I have my doubts that the new extruder housing design will suddenly fix it, as my test with a fan and a hairdryer did not improve anything. Also I would assume that there a user in hotel parts of the world that don't operate in a air conditioned environment and might have a temperature of 30C or even above all the time. I guess they would have reported this issue as well.

As I use the MK3 commercially that problem really sucks, no print, no business. I was about to order a new MK3 as I could not fix the issue, but now I am glad I found this post and did not.

Re: MK3 extruder randomly skipping

Print speed is now 70 mm/s(is fast i think), try 50 mm/s or 40 mm/s.(50 mm/s is standard in slicer).

With infill speed of prusa with of 180 or 200 mm/s, i had the same issue

Make this 100 mm/s.

With big flat parts infill, the prusa could not do the job.

To slow is also not good, then it gets to hot, hot weather and a encloser could also be a problem, leave door open with pla prints.

The skipping for me is gone at the moment.

Normally i print the standaard settings of slis3r,

temp filament, pla 220 or 215,

speed infill to 150 or 100(standaard 180 or 200).

top fill i leave at 50 mm/s

This is for 0.2 prints in slic3r.

Higher speeds you can do a test with temps,

print at high speed, turn temps higher, you wil see that it wil not go up, because it goes to fast, try this with 180 or 200 speed, is very strange that this is a standaard speed setting, if you(we) fill in a big part you have problem.

And often lower speeds helps for a lot of problems, especially if you can not find the problem.

And good luck.

Re: MK3 extruder randomly skipping

Printing at 200C to reduce the chance of a heat creep, having the new R3 extruder body installed and a 12cm 12V fan blasting directly into the cold end and the stepper motor, I just finished a 4 hour otherwise flawless print with this .. it's so bloody annoying!

It's clearly not the problem with cooling (the fan blows enough air to keep myself cool 10 feet afar, let alone the radiator and the stepper in 3 inch proximity), it's the problem with how the printer feeds the filament at short layer times !

Re: MK3 extruder randomly skipping

I am with you, the problem sucks. I reactivated one of my cheap $150 Chinese printers and for the first time ever the little Ender 2 from Creality produces better prints than my $1000,- MK3. Same models and same filament, no issues.

I normally use Simplify 3D as slicer, I meanwhile also tried Cura which I used before on my Chinese printers and even Slic3r PE. All produce different G-Code, but all prints have the same issue.

The only thing that came to my mind today was the firmware. I always updated it when a new version was available. Besides the unusual hot wether this is the other thing that changed one my MK3. I might give it a try to downgrade to something like V3.1.3 when I have time.

Re: MK3 extruder randomly skipping

Since I commented on page 1 , I've rebuilt my extruder assembly with a copper E3D heater block, a ruby nozzle, a new PTFE tube and a new heat-break from Prusa. I'm sad to say that I'm currently listening to the familiar "tick, tick, clunk" from my MK3's extruder gears slipping as it tries to print a simple PLA model.

I've printed the R3 extruder parts, but I'm reluctant to take my extruder to bits again until I see more positive feedback about the mod.

My old MK2SMM was an amazing printer, yet this MK3 remains mostly a disappointment to me TBH.

Re: MK3 extruder randomly skipping

Some Update, but no fix for the problem.

last week I was thinking if they use MK3 in the Prusa Factory to produce the printer parts and if they might similar issues when all those printers produce a lot of heat. But then came to my mind that they don't print in PLA, but PETG. And apart that the black and orange was not in stock, there was also a 5% discount on those PETG filament.

So I ordered PETG from Prusa, which arrived today. I can print absolutely flawless with PETG. Fabulous details and no stringing. Seems to be a good PETG that Prusa sells, I got much worse. But the point is that PETG I more heat resistant than PLA, even if you have to print it at higher temp. It works.

That would lead back to treasure, but as dmitrys and my own experiments with a hair dryer have show it is not only the small Noctua 5V Fan and the amount of air. Not sure what to do about the PLA. But at least I am back in business with PETG.

Maybe I have now a Prusa MK "PLA only in Winter" printer 😀

Hopefully Joseph and his team come up with some ideas why the MK2 performs better than the MK3 when the wether is hot and you want to print PLA.

Re: MK3 extruder randomly skipping

Some Update, but no fix for the problem.

last week I was thinking if they use MK3 in the Prusa Factory to produce the printer parts and if they might similar issues when all those printers produce a lot of heat. But then came to my mind that they don't print in PLA, but PETG. And apart that the black and orange was not in stock, there was also a 5% discount on those PETG filament.

So I ordered PETG from Prusa, which arrived today. I can print absolutely flawless with PETG. Fabulous details and no stringing. Seems to be a good PETG that Prusa sells, I got much worse. But the point is that PETG I more heat resistant than PLA, even if you have to print it at higher temp. It works.

That would lead back to treasure, but as dmitrys and my own experiments with a hair dryer have show it is not only the small Noctua 5V Fan and the amount of air. Not sure what to do about the PLA. But at least I am back in business with PETG.

Maybe I have now a Prusa MK "PLA only in Winter" printer 😀

Hopefully Joseph and his team come up with some ideas why the MK2 performs better than the MK3 when the wether is hot and you want to print PLA.

This issue is already addressed and fixed. Try the new R3 extruder parts.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: MK3 extruder randomly skipping

This issue is already addressed and fixed. Try the new R3 extruder parts.

Really? Because I see zero difference as backed up with photos in my previous post.

Re: MK3 extruder randomly skipping

This issue is already addressed and fixed. Try the new R3 extruder parts.

Really? Because I see zero difference as backed up with photos in my previous post.

No need to be sarcastic.

It worked for me. Parts which tend to fail with R2 are now working fine with R3. Sasha have not tried R3 yet. If you don't see any difference it doesn't mean nobody see it.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: MK3 extruder randomly skipping

Are you using Slic3rPE? If so, take a look at Filament Settings->Advanced->Print speed override->Max volumetric speed setting. For PLA, the Prusa profile is set to 15, which is actually a bit over the capacity of the E3D V6 of ~11.5mm^3/s. For PLA, it's set to 8, which is well below. Just for laughs, try setting it to 8 for PLA and try your problem part again. Does that help?

[...] I can print absolutely flawless with PETG. Fabulous details and no stringing. Seems to be a good PETG that Prusa sells, I got much worse. But the point is that PETG I more heat resistant than PLA, even if you have to print it at higher temp. It works.

If you're not using Slic3rPE, it might be worth firing it up for this little experiment. Whenever I've had extruder clicks, kicks or skips, I tweak this way back for the filament, then increase it until I hit the problem again. Knock it back below that and I'm golden. I'm always annoyed when I switch slicers and have to reverse-engineer speeds to do the same thing, particularly Simplify 3D. I'm not updating my extruder until I'm convinced I need to and that the new design is as quiet. So far, no issues even with the (somewhat) elevated ambient temps (~76F/24.5C).

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

Prusa Support told me they might start to produce the R3 parts in 2 weeks or more. I guess I am going to order them as the black PET is not in stock.

And I don't want to experiment with other filament vendors as the PET that Prusa sells is the best I ever got and I don't ant to spend 50€ or more for a spool. So as soon as either the R3 parts or the black PETG is in stock I will give it a try.

But as we get the suggestion very often to slow down the speed, that does not make sense to me. As we experience the problem when printing slow. I think if the filament is longer in the hot end it has more time to get soft and this would increase the problem.

As long as I am printing fast, even huge objects with no details and plan surfaces it seems to work, until it comes to the top layer which is printed at lower speed. Even a solid(100% infill) seems to be fine as long as the filament is pushed quickly thru the hot end.

Re: MK3 extruder randomly skipping

One thing to the recommendation to tighten the extruder gears. I did that and the filament was during out above the hot end. Despite what the manual says, but there is a video in this Joseph explains to tighten the pully just to the moment it grabs on the filament. It did this and it works for me on PLA and PET. I have not tested anything else for far, but I don't expect a difference with TPU or Nylon. If the temperature is right ans everything set up correctly it does not take a lot of force to push the filament to the hot end.

But it did not change anything on the problem discussed here.

Re: MK3 extruder randomly skipping

I've been trying to print a simple stack-able tray. Nothing fancy. Three failed attempts with PLA. Printed in PETG perfectly first time.

I'll fit the R3 extruder bits this weekend and repeat the PLA tray print and see if it makes any difference.

Re: MK3 extruder randomly skipping

The frustrating part about this problem is that it might have multiple causes. Most of the recent discussion lately has been focused on heat issues, which are becoming apparent in the hot summer months. However, skipping can be caused by other sources, particularly if you're pushing filament faster than it can be processed by the E3D V6 extruder. I had this problem even in the winter months.

I've been trying to print a simple stack-able tray. Nothing fancy. Three failed attempts with PLA. Printed in PETG perfectly first time.

If your problem is limited to PLA and you can print just fine with PETG, it's worth taking a look at what settings are different between the two. If you're using SLic3r, take a look at Filament Settings->Advanced->Print speed override->Max volumetric speed. For PLA, the Prusa presets have it at 15. For PETG, it's 8. That setting throttles how fast filament is fed through the extruder based on volume. The E3D V6 can handle about 11mm^3/s. 15 is obviously over this. Since you're waiting for parts, it might be worth trying PLA with this setting cranked down to 8 to see if that fixes things. It may be a bit slower overall, but your printer will still be able to hit your speed settings provided it is processing filament at a speed the extruder can handle. It will back off until it can.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

The skipping issue can have (at least) 2 causes: Heat creep, particularly in the summer months, and feeding filament through at a rate the E3D V6 extruder can't handle. I've had skipping in cold winter months, and was able to adjust it by limiting max volumetric speed. Not exactly the same thing as overall slowing down, but it does have the effect at limiting speeds to what the E3D V6 can actually handle.

[...] But as we get the suggestion very often to slow down the speed, that does not make sense to me. As we experience the problem when printing slow. I think if the filament is longer in the hot end it has more time to get soft and this would increase the problem.

As long as I am printing fast, even huge objects with no details and plan surfaces it seems to work, until it comes to the top layer which is printed at lower speed. Even a solid(100% infill) seems to be fine as long as the filament is pushed quickly thru the hot end.

The more recent spike in extruder issues seems to relate more to cooling during the hot summer months. You're right that faster printing may allow the filament to flow more smoothly, but it's worth looking at what contributes to the extruder motor heating up enough to cause heat creep in the 1st place. Excessive retractions can be part of this. I generally recommend trying a slower speed as an initial test because it will both reduce the rate of retractions (artificially) and reduce filament being pushed through the E3D V6 extruder. It's just a test though. If slowing down works, you can try adjusting max. volumetric speeds or retraction rates without any hardware mods. If not, you know you need the hardware mods.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

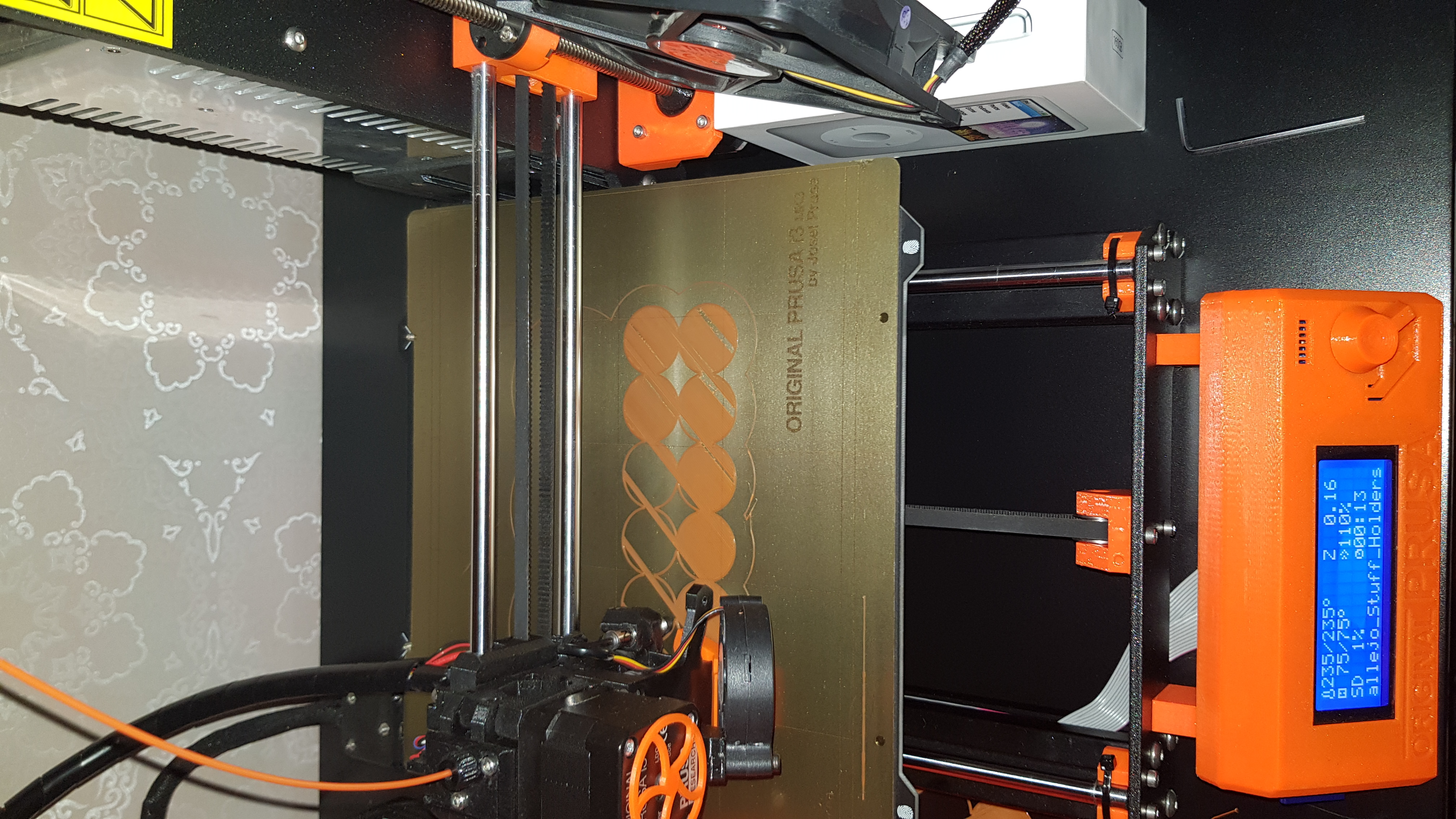

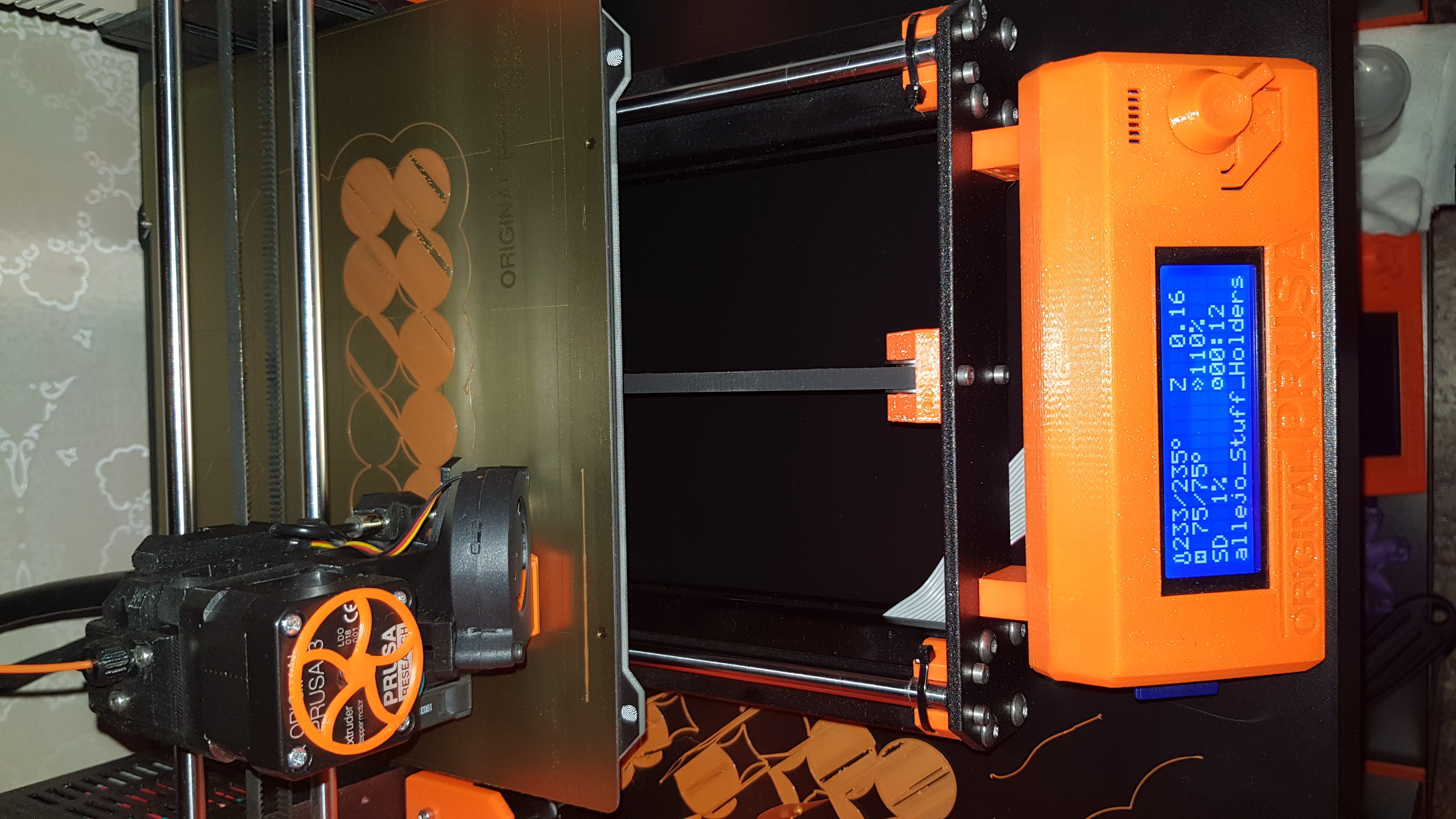

I've been trying to print a simple 3 bottom layer 2 perimeter dropper bottle holders 7 times now in PETG slicing with Cura, S3D, Slic3r and every single time I get random skips in the infill. Trying to print this in PLA was an even worse nightmare..

Started to get very frustrating as for the past 2-3 weeks I've done nothing but wasted filament and electricity.

Re: MK3 extruder randomly skipping

Those 1st layers don't look good at all. Can you get a clear picture of just the 1st layer prints that's a bit better focused? If you're worried about parts not being filled in on each circle, let the layer finish. The slicer will often complete long lines, then come back and fill in shorter lines on the same layer before going to the next.

I've been trying to print a simple 3 bottom layer 2 perimeter dropper bottle holders 7 times now in PETG slicing with Cura, S3D, Slic3r and every single time I get random skips in the infill. Trying to print this in PLA was an even worse nightmare..

Hard to say for sure without a clearer pic, but even your purge line looks distorted. I suspect your Z is too low. There's absolutely no sense in trying ambitious prints if you don't have your 1st layer working well. I'd suggest going through the "life adjust" thread and using those files to work on the 1st layer. When you think you've got that set properly, try a more ambitious 1st layer test. Only once you can print through that without issue should you bother with anything larger. (Apologies if you've done so, just going by your last pics.)

Edit: I've re-read your prior posts, and your other prints seem to have made it further along. Those 1st layers aren't what I would expect to see, but you need to fix that before anything else can have a chance of working. Clearer pics may show something else, but it really looks like your nozzle is dragging and you need to back off on your Live-Z (use a less negative) number.

Another edit: Your extruder and heated bed wires look to be mashed up against the wall when the Y axis is fully retracted in your 2nd pic. That's not a good idea and can cause problems. Suggest moving the printer out or moving it somewhere where they are not obstructed.

Yet another edit: Vallejo paint holders? Are you doing miniatures? Is that an old school iPod box?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

It's all the same nissue, really. You can right click the photos and open them in new tab for full res images. That should give you better clarity of what's not been filled yet and what has been skipped with residue.

This is a result of having first layer on PETG prints slowed down to 35mm/s. If I bump it to at least 50-60, the layer fills absolutely fine yet it will tend to fail to stick properly or will lift in spots due to faster movement as PETG likes it slow... subsequent layers after the first layer will start to deposit without gaps like these.

Re: MK3 extruder randomly skipping

Yes, I've done that. There appear to be places on the 1st layer where the nozzle has snagged the surface. At least from what I can make out when zoomed in.

It's all the same nissue, really. You can right click the photos and open them in new tab for full res images. That should give you better clarity of what's not been filled yet and what has been skipped with residue.

This is a result of having first layer on PETG prints slowed down to 35mm/s.

The front panel is showing 110% ?

If I bump it to at least 50-60, the layer fills absolutely fine yet it will tend to fail to stick properly or will lift in spots due to faster movement as PETG likes it slow... subsequent layers after the first layer will start to deposit without gaps like these.

PETG in good condition should have no issues adhering. At this point, something is clearly wrong with the 1st layer, either due to Live-Z or bed conditions. However, if you're not interested in trying things, I won't bother you any more.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: MK3 extruder randomly skipping

❗

Yes, I've done that. There appear to be places on the 1st layer where the nozzle has snagged the surface. At least from what I can make out when zoomed in.

It's all the same nissue, really. You can right click the photos and open them in new tab for full res images. That should give you better clarity of what's not been filled yet and what has been skipped with residue.

This is a result of having first layer on PETG prints slowed down to 35mm/s.

The front panel is showing 110% ?

If I bump it to at least 50-60, the layer fills absolutely fine yet it will tend to fail to stick properly or will lift in spots due to faster movement as PETG likes it slow... subsequent layers after the first layer will start to deposit without gaps like these.

PETG in good condition should have no issues adhering. At this point, something is clearly wrong with the 1st layer, either due to Live-Z or bed conditions. However, if you're not interested in trying things, I won't bother you any more.

Those are places where the nozzle stopped extending as can be seen from the little beads left behind, a tell tale sign of underextrusion. A nozzle dragging on the solid infill looks entirely different.

110% from default 30mm/s speed in Slic3r is 33mm/s. Perhaps "slowed down" wasn't the term to use...

Believe it or not, I've tried dozens of things for the past 2-3 week and every thing points to the printer not coping with pushing the filament through at the lower speed. I'm well aware about how a good first layer looks like and how to achieve it, the whole point of this thread it to showcase an imminent problem that doesn't go away with firmware updates, extruder body replacements nor blasting cold air at the hotend and extruder motor.

Another edit: Your extruder and heated bed wires look to be mashed up against the wall when the Y axis is fully retracted in your 2nd pic. That's not a good idea and can cause problems. Suggest moving the printer out or moving it somewhere where they are not obstructed.

Yet another edit: Vallejo paint holders? Are you doing miniatures? Is that an old school iPod box?

That's camera perception, there's at least 15cm clearance between the wires and the wall.

Not miniatures, just regular print and paint shenanigans. And that would be a "yes" for the iPod box.