Re: Many new printed parts on GitHub

Just join the dark side and print the upgrades in black. I will only have two orange parts left when I get more m3 screws Wednesday, looks so much more sophisticated. 🙂

Haha, I will thinking about it. 😀 The Black PETG from PM Filament is in the stock (only 2 kg option), but I want to wait for powder steel sheet anyway.

Re: Many new printed parts on GitHub

I really like the orange 😡

Has anyone got to any conclusion on what brand the Orange filament is??

I have some Blue Prusa PETG (transparent).... i might give that a try except for the Extruder body which will be the default black :p

EDIT: In other post talking to some users someone said it's from ColorFABB....

And you can see this on their video:

That Label is from one of the PETG spools on the farm.... any detectives out there?

Re: Many new printed parts on GitHub

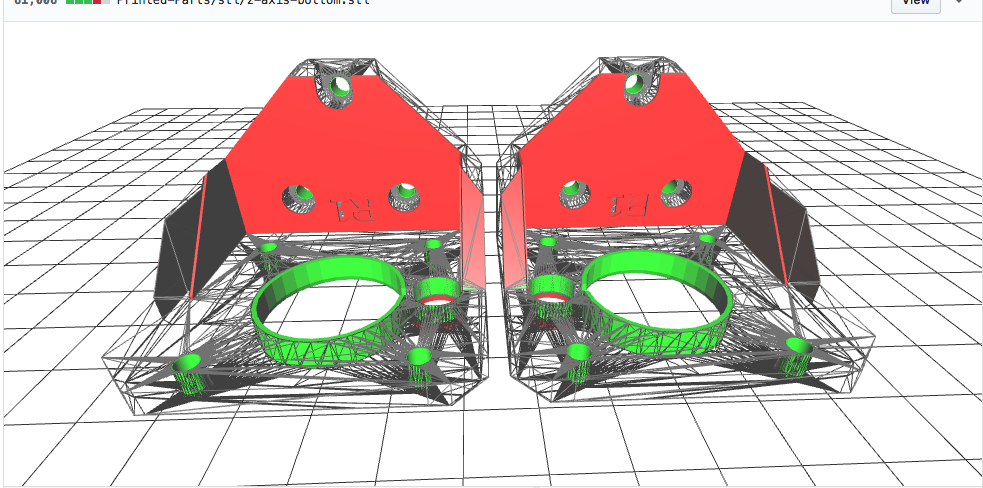

From what I can see, they haven't' correctly the misalignment on the Z-Axis between the rods and threaded shafts, as documented by RHDreambox.

Does this mean they don't accept his findings? Or don't think it warrants a change?

Why do you say that? They widened the box and tighten the motor, rod, and screw holes.

Re: Many new printed parts on GitHub

I really like the orange 😡

Has anyone got to any conclusion on what brand the Orange filament is??

I have some Blue Prusa PETG (transparent).... i might give that a try except for the Extruder body which will be the default black :p

EDIT: In other post talking to some users someone said it's from ColorFABB....

And you can see this on their video:

That Label is from one of the PETG spools on the farm.... any detectives out there?

I will try to find out because I have ordered thier orange PETG and UPS shoul deliver it tomorrow. Before I made my order I've ask support if orange PETG from e-shop is in the same colour as orange printed parts in MK3. They said no and if I want the same colour I should leave a note in my order to get the correct one.

Re: Many new printed parts on GitHub

I really like the orange 😡

Has anyone got to any conclusion on what brand the Orange filament is??

I have some Blue Prusa PETG (transparent).... i might give that a try except for the Extruder body which will be the default black :p

EDIT: In other post talking to some users someone said it's from ColorFABB....

And you can see this on their video:

That Label is from one of the PETG spools on the farm.... any detectives out there?

I will try to find out because I have ordered thier orange PETG and UPS shoul deliver it tomorrow. Before I made my order I've ask support if orange PETG from e-shop is in the same colour as orange printed parts in MK3. They said no and if I want the same colour I should leave a note in my order to get the correct one.

That’s different to what they told me on the chat, I said is the PETG Orange the same and what the mk3 is printed in and they said yes it’s the same pigment, so who knows lol. It should be here soon but I don’t have my mk3 yet 🙁

Re: Many new printed parts on GitHub

it says Prusa Ngen

its upside down in the picture

Re: Many new printed parts on GitHub

Sure it doesn't say "PRUSA NEON"

Re: Many new printed parts on GitHub

If you were going to reprint the x axis parts right now would you go with the prusa parts or the zaribo parts?

Re: Many new printed parts on GitHub

Sure it doesn't say "PRUSA NEON"

It does say Prusa Neon. Not ngen. Most likely a custom roll possibly made by Prusa themselves.

Re: Many new printed parts on GitHub

If you were going to reprint the x axis parts right now would you go with the prusa parts or the zaribo parts?

I think I'm going to go with Prusa R2 for X ends. Zaribo is fine, but I prefer the tensioning solution of Prusa (same way I was going to solve it). Either should work. I also wonder why Prusa reinforced the trap nut area. Anyone know? I'll go with that for now.

X carriage is another story. I don't like either. I don't like the captive wires in the X back (even with my belt access change). The Zaribo MK2 style is better but I need to mod it to work with MK3.

Re: Many new printed parts on GitHub

If you were going to reprint the x axis parts right now would you go with the prusa parts or the zaribo parts?

I would have printed the zaribo x end, i think their tensionning solution is better than the one from prusa.

If i understood correctly, Prusa do it by rotating the motor around a fixing screw, so the belt would not be perfectly alligned with x end idler and x-carriage.

On the zaribo, you adjust the x end idler by translate it on the x axis so it would alway be in the same line as the x-end motor and x-carriage.

what do you think ?

x-end-idler and X-end-motor R2_Brass Lead Screw Nut

Hi, sorry for my english, I'm french..

Anyone has make the x-end-idler and X-end-motor R2 who can receive the 8mm Brass Lead Screw Nut ?

Thank you

Re: x-end-idler and X-end-motor R2_Brass Lead Screw Nut

Hi, sorry for my english, I'm french..

Anyone has make the x-end-idler and X-end-motor R2 who can receive the 8mm Brass Lead Screw Nut ?

Thank you

Pourquoi ?

Je reçois ma commande demain, d’après le chat j'aurais la dernière révision des pièces donc au moins R2.

---------------------------------------------------------------------------------------

Why ?

I receive my order tomorrow, according to the chat I will have the last revision of the parts so at least R2.

Re: Many new printed parts on GitHub

If you were going to reprint the x axis parts right now would you go with the prusa parts or the zaribo parts?

I would have printed the zaribo x end, i think their tensionning solution is better than the one from prusa.

If i understood correctly, Prusa do it by rotating the motor around a fixing screw, so the belt would not be perfectly alligned with x end idler and x-carriage.

On the zaribo, you adjust the x end idler by translate it on the x axis so it would alway be in the same line as the x-end motor and x-carriage.

what do you think ?

The maximum deflection on the belt is about 0.5 mm which is less than the height of 1 tooth, i.e. less than half the thickness of the whole belt. This is inconsequential.

Re: Many new printed parts on GitHub

WARNING !!

There is a flaw in this design from Zaribo: https://www.thingiverse.com/thing:2786603/#files

One of the most critical dimensions on your printer is the Z reference, which should be obvious from all the pain to mesh level and Live Z, etc. The first step is leveling the X gantry against a known reference. This reference is the screw heads (on the pre-drilled Z frame) against the top edge of the X ends. The reason the X end are printed on the narrow edge instead of the more obvious large flat back side, is to make this top edge a perfectly flat reference. Unfortunately, Zaribo, in their over-enthusiastic filleting, went and filleted this edge. So it is curved, so accuracy is lost, but worse will not print clean (don't fillet against the bed - this is FDM not CNC!). So your actual critical dimension is lost. You might get lucky but I would not use these.

Re: Many new printed parts on GitHub

If you were going to reprint the x axis parts right now would you go with the prusa parts or the zaribo parts?

I would have printed the zaribo x end, i think their tensionning solution is better than the one from prusa.

If i understood correctly, Prusa do it by rotating the motor around a fixing screw, so the belt would not be perfectly alligned with x end idler and x-carriage.

On the zaribo, you adjust the x end idler by translate it on the x axis so it would alway be in the same line as the x-end motor and x-carriage.

what do you think ?

The maximum deflection on the belt is about 0.5 mm which is less than the height of 1 tooth, i.e. less than half the thickness of the whole belt. This is inconsequential.

And don't you think it's better to do the setting on the lightest part ? (x-end idler)

I'm concerned that with time, vibrations and motor weight, the setting will move more easily

However, I think i will receive it with R2 revision and it will stay like this if it work well 😀

EDIT : Well seen, i don't think about this, but I still prefer the setting system

Re: Many new printed parts on GitHub

I would have printed the zaribo x end, i think their tensionning solution is better than the one from prusa.

If i understood correctly, Prusa do it by rotating the motor around a fixing screw, so the belt would not be perfectly alligned with x end idler and x-carriage.

On the zaribo, you adjust the x end idler by translate it on the x axis so it would alway be in the same line as the x-end motor and x-carriage.

what do you think ?

The maximum deflection on the belt is about 0.5 mm which is less than the height of 1 tooth, i.e. less than half the thickness of the whole belt. This is inconsequential.

And don't you think it's better to do the setting on the lightest part ? (x-end idler)

I'm concerned that with time, vibrations and motor weight, the setting will move more easily

However, I think i will receive it with R2 revision and it will stay like this if it work well 😀

EDIT : Well seen, i don't think about this, but I still prefer the setting system

I’d be concerned if it was just held by friction of screws on front plate, but the tension screw holds it as well to lock it in. I’ll find out soon as I’m printing the replacements now.

Re: Many new printed parts on GitHub

Just for your info. I received my MK3 kit yesterday (ordered 22.11.2017) and still the "old parts", but who cares..........I have bigger problem. My Einsy was f...n death. Now I have to wait for replacement. 😳 Prusa support are just amazing. I spent over 2 hours on chat trying to fix the problems unfortunately no success.

Re: Many new printed parts on GitHub

WARNING !!

There is a flaw in this design from Zaribo: https://www.thingiverse.com/thing:2786603/#files

One of the most critical dimensions on your printer is the Z reference, which should be obvious from all the pain to mesh level and Live Z, etc. The first step is leveling the X gantry against a known reference. This reference is the screw heads (on the pre-drilled Z frame) against the top edge of the X ends. The reason the X end are printed on the narrow edge instead of the more obvious large flat back side, is to make this top edge a perfectly flat reference. Unfortunately, Zaribo, in their over-enthusiastic filleting, went and filleted this edge. So it is curved, so accuracy is lost, but worse will not print clean (don't fillet against the bed - this is FDM not CNC!). So your actual critical dimension is lost. You might get lucky but I would not use these.

Whew, dodged that one. I almost went that route. 🙂

This makes me wonder, has anyone printing the R2 parts been checking height from the X rods to the top of the plastic piece? I printed mine off the other day and have a .01mm difference between left and right sides that I figured would play into a slightly off Z calibration. I am going to wet sand the offending part down until they both match.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Many new printed parts on GitHub

Just wanted to let everyone know that I converted the new R2 files to STEP format and posted them on my GitHub fork (as well as GrabCAD and Thingiverse).

They are available for download here:

https://github.com/jzkmath/Original-Prusa-i3/tree/MK3/Printed-Parts

I will post the SolidWorks model if/when I have time to do so, as my course-load is really picking up!

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis