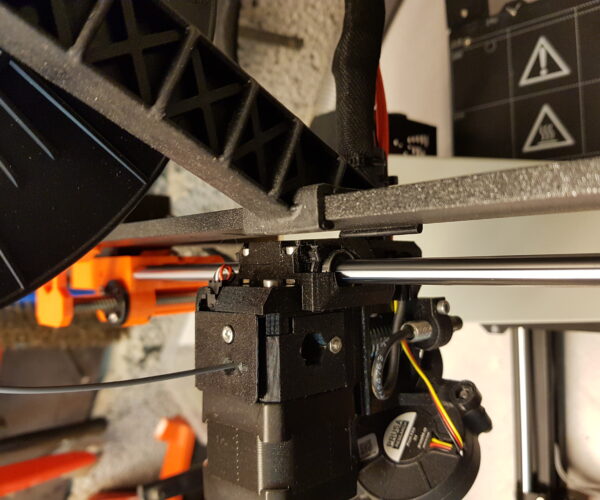

High prints fail, motor bracket hits spool holder.

If you look closely at the pictures you can see that the motor bracket just barely touches the lower grip of the spool holder. This caused two high prints to fail before I realized what was wrong.

Has anyone else seen this? How much air is between theese parts on your printer? (Build height about 200mm)

Did I assemble the printer correctly?

RE: High prints fail, motor bracket hits spool holder.

Is it the black housing that hits the spool holder bracket edges, or is it the Zip Tie that is hitting?

If you install the Zip Tie 90 degrees off from how it should be, the zip tie housing or cut-end can be sticking out too far.

Failing that ... get a big file and file down the thickness of your spool holder and a little file to thin down the extruder housing.

But I bet on the zip ties.

RE: High prints fail, motor bracket hits spool holder.

Your x axis backplate looks like it isn't sitting flush and so is sticking out more than it should. If it was flush it would clear the bracket.

RE: High prints fail, motor bracket hits spool holder.

I agree with Neophyl on this - your print head is not assembled correctly. On my printer, they come close, but they clear by a mm or more. When I designed low profile spool holder arm replacements, this spacing was a critical design element.