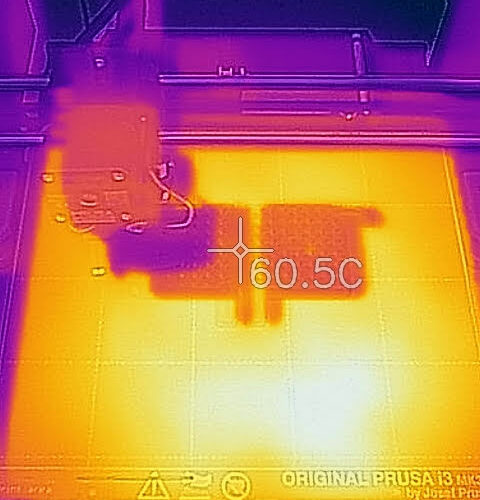

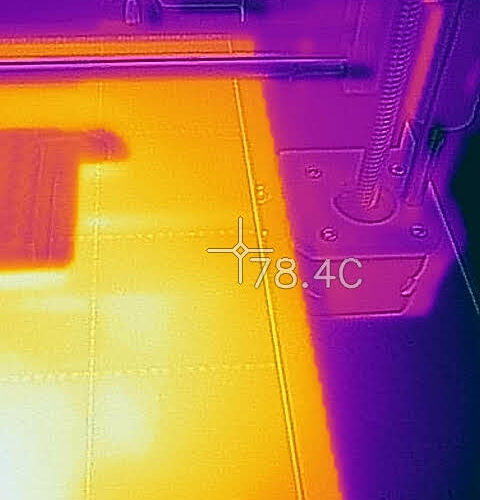

Heatbed consistency of temperature across surface

Maybe this post will help someone else, maybe others will comment and say I'm wrong (and I am very open to learning if so!)

I've just started printing in Prusament PETG onto Prusa Textured Sheet and PEI Sheet, and have encountered a whole new world of difficulties with prints either not sticking to the bed, or sticking too much and slightly damaging the PEI plate upon removal. ("Damage" is the wrong word, just a tiny variation in colour where the corners of a few squares of print were.)

I hear most people talking about the importance of using glue sticks for adhesion, Windolene/Windex to make removal easier, etc. More specifically or PETG they talk about print speed (some say high and give reasons, some say low and give reasons).

Personally I have given up on using glue or windolene like it's going to solve problems, and focused on the temperatures, geometry of the print and position on the heatbed (the outer edges are not as hot), and printer settings such as speed and retraction.

For example I'm printing parts for the Ikea Lack table, the footprint is square with little rectangles coming off the corners. I found that if I placed the corners with protruding rectangles on the side edges of the print bed, they start to lift, presumably because this part of the bed is not as hot as the centre.

- The parts in the centre seem much better.

- Also I have found that you can NOT print in Stealth Mode as it causes too many problems, at least with the PETG parts I am printing.

- Regarding removal, I find it depends on the size of the footprint: if it's large enough the bend in the sheet allows easier removal. No knife, just bending and a bit of pushing.

- Regarding the textured bed, I've had limited success getting the first layer to stick. I think this was closely related to my first layer calibration though.

- Either way, I am trying to print without messing up the nice bed with glue, hairspray, etc. After removing all this gunk with hot soap and water, it rarely needs cleaning or any other surface prep at all.

Here's an example of heatbed temperatures (two parts in the middle, printing very nicely). Bed is set to 90 in the software. Using the smooth sheet.

Anyone else notice this?