Having some issues printing

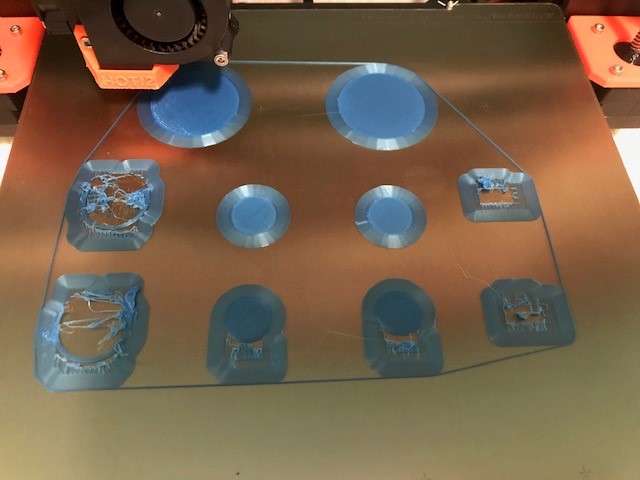

Hello all, Well I seem to be having a problem printing now. I have had the printer for a few months now and have had issues in the past with PLA Sticking to to print bed on first layer. I started out with the powder coated sheet and have never been very successful getting anything to stick to it. I since bought a regular prusa steel sheet and had much better luck printing. For the last two months my printer printed like a charm and almost never messed up anything on a print. Recently, my printer is back to having trouble sticking to the metal sheet, causing almost all prints to fail. I have re-calibrated multiple times, adjusted the first layer, cleaned everything and moved it to different rooms to see if heat or cold was affecting it. So far i have had no luck getting it to print. The other thing I have noticed is the printer is not as quiet as it used to be and seems to make more noise now. I have oiled the rods and checked for any plastic debris. When I do brims now they seem a little rough compared to when I would print them before. Here is a failed print that should be an easy one. feeling a little frustrated about not being able to print after it working so wonderfully before. Any help would be appreciated.

[img]

Re: Having some issues printing

I’d start by cleaning the print bed with dishwashing liquid. Any time I have adhesion problems it does the trick.

Re: Having some issues printing

Did you upgrade firmware? Seems some think the latest firmware has caused them issues on multi-part prints.

I had a similar "everything failed" experience with a new spool of filament; things got better after I used up about 6 meters wasting time on various attempts to print. I suspect the manufacturer had an employee who was using hand cream do the final tie off and wrap of spools. Once the first layer of filament was gone, prints came out fine. My avatar was taken during that learning event.

I know it's cliche, but I've learned that some soaps don't rinse clean, and I now depend on alcohol and acetone to keep the bed sticky clean - and never touch the bed surface with my fingers. I only use tools (pin point tweezers and plastic spatulas, aka spudgers) to remove parts and fragments.

Last suggestion, if anything gets under the bed, it will cause a high spot. Since the middle parts seem to stick, and the edges aren't... any chance there's debris under the middle of the steel sheet? We're talking thousandths of an inch, so most anything will compromise flatness.

Re: Having some issues printing

Yes, I did just upgrade all the firmware. I've managed to print items that do not have support ok, although they still seem a little rough. It seems to be the worst one support lines. I slowed it way down to 50% and managed to get some printed but the lines were still turning up at the edges.

Re: Having some issues printing

What do you mean "turning up at the edges"? When my print bed is dirty, layer 1 will turn up at the edges of support strips or not stick at all.

Soaps and detergents are surfactants and if not entirely rinsed off will cause print problems; and softer water makes adequate rinsing more difficult. That's why an alcohol rinse is recommended as the last step in cleaning a bed. And acetone can remove PLA residue and etches the PEI to a "like new" finish. However, because acetone dissolves PEI you don't want to use too much or use it too often.

A photo would help.

Re: Having some issues printing

1- Clean your hands,

2 - I had the same problem, then after washing 3 x times with dish washing soap(let the dirt get soft), it was ok again,

put steel plate on printer, then clean it again with 98 % alcohol, then print.

(you could also do first clean with disk wash, then clean with acetone, if you print all day long do this 1 of 2 a month.)

3 Let steel plate cool down, then you can take off print, steel plate need te be cool, otherwise you will damage it.

4 Try different filament , pla abs etc, different brand.

(calibrate z layer with the printer hot). And pla and abs there is temperature difference.

I had if i did first layer, there was air under de first layer, then you know it is wrong.

I had after testing that the nozzle was to close to the bed, check this, if it is to low, it wil not get enough filament to the plate, you could try with the nozzle to high, and then lower it with steps, then suddenly you will see it is ok again.

I had also that prints always workt, then suddenly it failed, everything.

After good cleaning, z layer calibration, and then first layer adjusting(with heated bed).

Z-layer adjusting could be different for every roll or different filament, in the beginning of print you could adjust this, a little of course if needed. Do this step slower if needed, or hotter, or make bed hotter.

First layer needs to be a little flatten to the steel plate, otherwise it does not stick, see example on the prusa site.

Also maintenance is needed, search for this.

And 3d printing production manufacturing, so you need to adjust things all the time.

Re: Having some issues printing

Yes, different spools of material, even from the same lot, can have different diameters. And normal diameter variation of 0.05mm sounds small, but allows for a 11% variation in filament volume. Consider that a 1st layer that has even 5% less plastic than the last calibration will not be a good layer.

Also, even spools rated +/- 0.03 can vary more than specified. Seems some manufacturers and retailers will claim much better specs than what is actually being sold. Was that 0.03 spec over the full spool, over 10 meters, etc. Caveat Emptor.

Since I started keeping the bed clean and watching layer 1 go down - I even adjust Z and flow as needed to ensure strand welding - my print failure rate has dropped to nearly zero. And I use the cheapest PLA I can find.