Ghosting / Vibration Artifacts

I posted this an hour ago, but that post seems to have been lost (forum reorganization?). Posting again (this is part of a post called "Rock Bottom" ... which seems to be gone now ...)

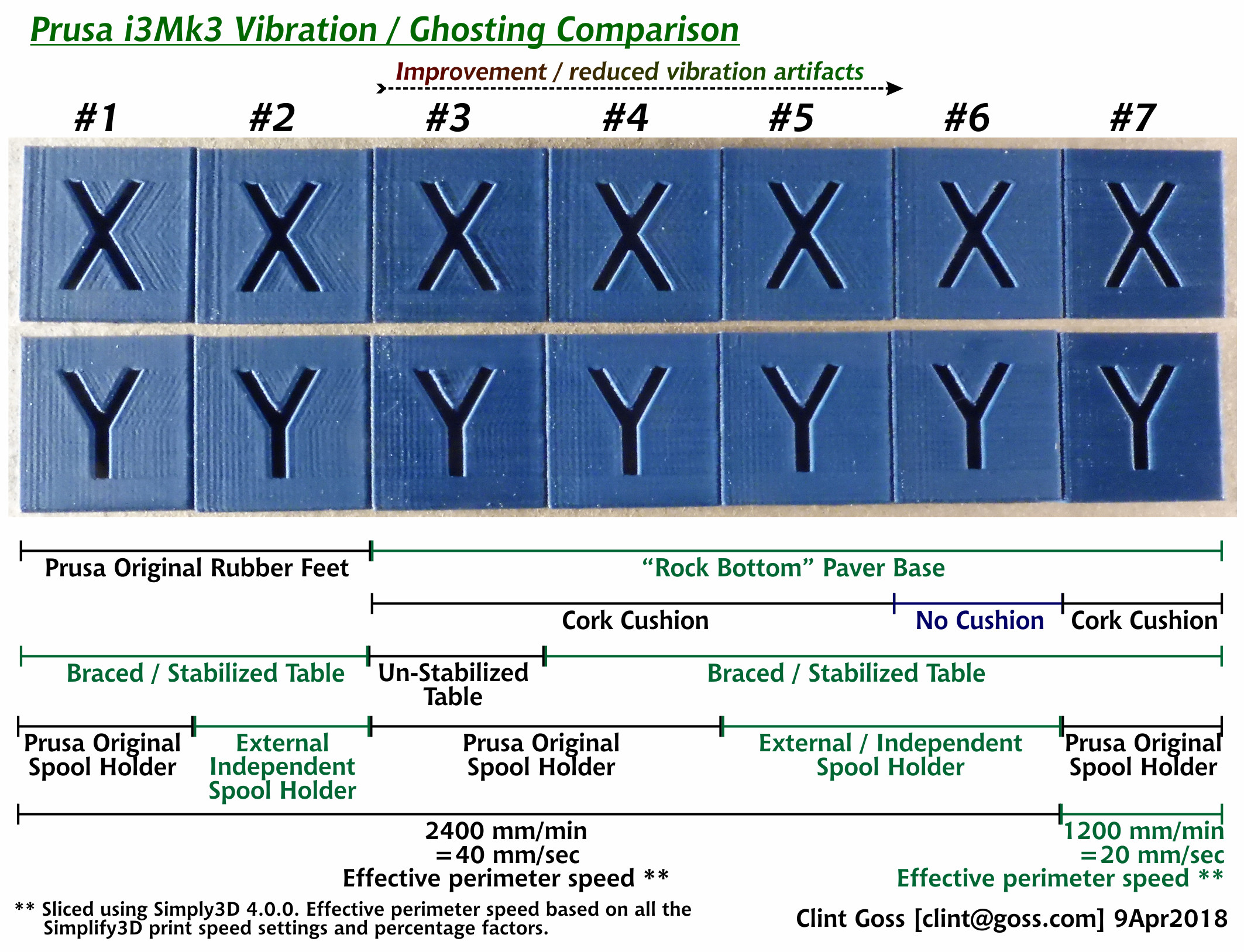

Here’s results of some testing I did over the last 3 days to identify issues causing ghosting / vibration artifacts.

For those who want an “executive summary”, here are my results: If you want to reduce, I believe that you should, from most effective to least effective (but still worthwhile):

(1) Print slower;

(2) Replace Prusa’s original rubber feet with a “Rock Bottom” style foundation;

(3) Brace your table/bench to something as stable as your house (assuming lack of external vibrations such as truck traffic);

(4) Consider an external spool holder,

(5) (least effective) Remove any cushion layer in the “Rock Bottom” setup and go for a more rigid “direct connection”.

For those who want the details …

I printed a set of 20mm XYZ Calibration Cubes ( https://www.thingiverse.com/thing:1278865 ) under different setup conditions. The comparison shows the X and Y faces of the prints, ordered to show improvement from left to right (although this is not the order they were printed). Print conditions were kept as stable as I could, including the same G-code, except for #7 which changed only the perimeter speed. Print details are provided at the end of this description.

On the assumption that multiple issues potentially contribute to ghosting, I tried to think of all the things that might contribute and that I could do something about. I came up with these five questions / things to test:

** How do Prusa’s original rubber feet compare with my “Rock Bottom” Home Depot Paver modification?

Compare tests #1 to #4 and #2 to #5. These two tests have the same conditions except for the rubber feet. There is a very noticeable reduction in artifacts.

** Is the thin Cork cushion that I included in the “Rock Bottom” setup worse than a more rigid “No Cork” setup?

Compare tests #5 to #6. There seems to be a slight, barely noticeable, possibly non-existent improvement. So slight that I’ve decided to use the cork cushion in my setup. I am concerned that a direct connection might wrench the frame rails out-of-true and the cork provides a compensation to this issue.

** The table / workbench I am using originally had wheels, which caused quite a bit of shaking. I removed them as sat the workbench directly on a carpet over the foundation slab. However, you could still feel shaking in the table. Rather than removing the carpet, I braced the table against the walls of the house, using wood blocks. Is that an improvement?

Compare tests #3 to #4. A noticeable improvement. There were many ways to couple the workbench to the house, but I had to come up with a reasonably aesthetic and non-damaging solution. I used blocks of very well-seasoned wood to brace the bench against the wall and between the wall and a very heavy cabinet.

** The stock spool holder from Prusa noticeably wobbles during prints. Is placing the filament spool external to the printer an improvement for ghosting / vibration artifacts?

Compare tests #1 to #2 and #4 to #5. There seems to be a small improvement.

In addition to reducing artifacts, I’m also concerned about frame issues that might be caused in the long-run by *any* frame-mounted spool holder … so I think this mod is a good one.

** What is the effect of print speed?

Compare tests #4 to #7 – the effect of a reduction to 50% print speed for perimeters is massive – I think the most significant contribution to reducing ghosting / vibration artifacts.

----

Details of prints #1 to #6. Print #7 was modified to reduce the speed

Clint Goss, 6Apr2018 to 8Apr2018, xyzCalibration_cube.stl, (thing:1278865, by iDig3Dprinting, 19Jan2016, CC-BY-SA)

Prusa i3Mk3 (SN CZPX1218X004XC53322, EINSY_04a, E3Dv6Full/0.4mm, 26Mar2018, FW 3.1.3-245)

S3D 4.0.0 Parameters (based on S3D-supplied Prusa i3Mk3 profile 23Mar2018):

Extruder: Noz 0.40, ExtMult 1.00, ExtWid Man 0.40, Retr 1.00, ExRestart 0.00, RVertLift 0.00, RSpeed 2400, Coast 0.2, Wipe 2.00

Layer: Ht 0.10, TSolid 4, BSolid 4, Shells 2, In-Out, No PI Seq, No Vase, FHt: 150%, FWid 100%, FSpeed 50%, Yes OptFast

Additions: Yes Skirt, Layers 2, Offset 1.00; Outlines 2 /

Infill: Int Rect, Ext Rect, 30%, OutOver 20%, Wid 100%, MinLen 5.00, Combine 1, No IncSolid, IntAng 45, -45, ExtAng 45, -45

Support: No

Temp: 200°C, 60°C

Cooling: 1:0, 2:100, No Blip, No Incr, No Bridge

G-Code: Yes 5D, No RelDist, Yes AllowZ, No Indep, No M101, Yes Sticky, No Offsets, Offset 0.00, 0.00, 0.00, Yes UpMachDef, Type Cart, Build 250, 210, 210, Orig 0, 0, 0, Home Min, Min, Min, Flip No X, Yes Y, No Z, Offset: X 0, Y 0, Yes UpdFirmConfig, Type RepRap, Baud 115200

Scripts: S3D Std Starting & Ending

Speeds: Default 4800 mm/min (=80mm/sec), Outline 50%, Solid Infill 80%, Supp 80%, X/Y Move 12000, Z Move 1000, No Adjust below 15sec, DownTo 20%

Other: Area 50, ExInflat 0.00, BrExMult 100%, BrSpMult 100%, No FixedAngle, No BrPerim, HCompress 0.00, FilDia 1.75, Price 46, Den 1.25, ChgRetDist 12, ChResDist -0.50, ChRetSp 600

Advanced: No Start, No Stop, ExThinType Perim, InThinType GapFill, Overlap 25%. MinExLen 1.00, MinPWid 50%, MxPWid 200%, EndExtDist 0.20, Yes Open, Yes ForceRet, No MinTRetr 3.00, Yes RetWipe, Yes WipeOuter, No AvoidCross, MaxDetour 3.0, NonManSeg Heal, No Merge.

MatterHackers Blue PRO Series PLA 1.75mm; 200°C / 60°C; Z=-0.725mm.

-- Clint Goss

Re: Ghosting / Vibration Artifacts

https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/rock-bottom-t15431.html

Re: Ghosting / Vibration Artifacts

Newbie here. I have been tinkering with by MK3 since I got it in December.

I had a decent amount of vertical striping in on the X face of the xyz cube and ghosting on the Y face.

I tried a few mounting options (no feet, thin silicone pad...) with little improvement.

What dramatically improved results for both was loosening the X and Y belts to the max reasonable (essentially just before self-test complains the belt is loose or skips a tooth). When I built the MK3 (my first 3D printer), I was thinking that a tight belt was better. However, a tight belt seems to also bring oscillations and ringing.

The easiest way to get rid of perimeter artifacts is still clearly to reduce perimeter speed.

Re: Ghosting / Vibration Artifacts

Newbie here. I have been tinkering with by MK3 since I got it in December.

I had a decent amount of vertical striping in on the X face of the xyz cube and ghosting on the Y face.

I tried a few mounting options (no feet, thin silicone pad...) with little improvement.

What dramatically improved results for both was loosening the X and Y belts to the max reasonable (essentially just before self-test complains the belt is loose or skips a tooth). When I built the MK3 (my first 3D printer), I was thinking that a tight belt was better. However, a tight belt seems to also bring oscillations and ringing.

The easiest way to get rid of perimeter artifacts is still clearly to reduce perimeter speed.

Overtightening the belts is exactly how i slightly damaged my XY motors.

Really tight belts produced awesome results at first, but then the ghosting and the ringing got worse over time. During a disassembly i noticed the X and Y motor shafts were slightly wobbling.

Lesson learned, new MK3's will get loose belts as much as i can get away with. Coupled with a third party toothed idler, this will work much better than the smooth idler the printer comes with.

May i ask what belt values you are getting after a printer calibration from the support submenu?

After power on make a printer calibration, i forgot if its XYZ calibration or selftest (most likely selftest), then go into support submenu and see belt statistics.

Prusa recommends a value of 240 +/-40.

Re: Ghosting / Vibration Artifacts

https://www.youmagine.com/designs/multi-angle-test-tower-for-calibrating-jerk

Just in case you are interested, this is a very nice tower for calibrating Jerk. Messing with Jerk settings can GREATLY improve the shadowing as well. (it will "round" out the corners a touch though, if set too high)

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Ghosting / Vibration Artifacts

After power on make a printer calibration, i forgot if its XYZ calibration or selftest (most likely selftest), then go into support submenu and see belt statistics.

Selftest will update the belt status support screen (though it also checks the hotbed/hotend temperature, so you have to wait a while between tests...grr).

If you do an XYZ calibration it'll wipe the calibration info and force you to go through that long process again (I found that out the hard way :|).

Re: Ghosting / Vibration Artifacts

Here's the original thread

Re: Ghosting / Vibration Artifacts

What kind of kork do you use? Sinple plates? How thick are they?

Re: Ghosting / Vibration Artifacts

Here’s results of some testing I did over the last 3 days to identify issues causing ghosting / vibration artifacts.

Great work Clint. Time to buy some concrete slabs !

Re: Ghosting / Vibration Artifacts

May i ask what belt values you are getting after a printer calibration from the support submenu?

...

Prusa recommends a value of 240 +/-40.

On delivery (a week ago, my first printer), Support => Belt Status reported:

X: 268

Y: 281

Currently:

X: 271

Y: 281

Now I'm a bit concerned ... I'm right at the upper limit of the recommended range ... And I know what *I* feel like with my belt too tight ...

-- Clint Goss

Re: Ghosting / Vibration Artifacts

What kind of kork do you use? Sinple plates? How thick are they?

My "Cork" layer is an optional, thin cushion layer between the top of the riser blocks that sit under the printer rails – for noise abatement and to compensate for any out-of-true situation cause by the paver (which *appears* level). I have Eco Cork Foam – 0.126” thick underlayment for engineered floors. (Home depot Model # 220000503, Internet #204700858, Store SKU #1001235985).

This material is somewhat compressible … one concern was that the cork under some parts of the printer will compress more and the printer will not sit flat.

Full details on my original post, which is now at https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/rock-bottom-t15431.html

-- Clint Goss

Re: Ghosting / Vibration Artifacts

On delivery (a week ago, my first printer), Support => Belt Status reported:

X: 268

Y: 281

Currently:

X: 271

Y: 281

Now I'm a bit concerned ... I'm right at the upper limit of the recommended range ... And I know what *I* feel like with my belt too tight ...

You're at the *lower* Level of the reccommended Range (meaning your belts are looser, not tighter)

From the Handbook:

"The belt status is a unitless number measured as an average load on the stepper motor.

Lower value corresponds to higher tension (higher motor load), higher value means looser

belt (less motor load)."

Re: Ghosting / Vibration Artifacts

It could be that your bearings are too smooth:-) Maybe sand the smooth rods:-)

What I am trying to say: I think these values can be ignored. Better to go by sound and feel...

Re: Ghosting / Vibration Artifacts

What I am trying to say: I think these values can be ignored. Better to go by sound and feel...

I wish I could ... but being my first printer and at this for 8 whole days, I have nothing to compare. However, things sound good to me!

-- Clint Goss

Re: Ghosting / Vibration Artifacts

What I am trying to say: I think these values can be ignored. Better to go by sound and feel...

I wish I could ... but being my first printer and at this for 8 whole days, I have nothing to compare. However, things sound good to me!

If you over tighten things, there will be damage. If you are too loose, there will be shifts in the print. I would advise you to read the build manual again. There is a test proposed to see if the belts "jump". If yours do not, they are not to loose. If they make a low sound like a bass guitar, they are not too loose either. If the tone is higher - I would be alarmed.

I am also no expert - I just think that one should not tune for the support menu belt values. Since good/bad bearings might influence the outcome, good/bad alignment might influence it too. The motors cannot measure the belt tension. They can only guess.

Re: Ghosting / Vibration Artifacts

What I am trying to say: I think these values can be ignored. Better to go by sound and feel...

I wish I could ... but being my first printer and at this for 8 whole days, I have nothing to compare. However, things sound good to me!

I would think you'd be better off following step 36 in the Y-Axis assembly instructions...

http://manual.prusa3d.com/Guide/2.+Y-axis+assembly/507?lang=en

I initially tried to adjust using belt status values and felt the tension was way too high. I believe Prusa is doing owners a disservice by having owners adjust their belts that way. FWIW, my belts read very similar tensions to yours and the tighter belt by feel is listed as being the loosest in my belt status...

Re: Ghosting / Vibration Artifacts

Overtightening the belts is exactly how i slightly damaged my XY motors.

Really tight belts produced awesome results at first, but then the ghosting and the ringing got worse over time. During a disassembly i noticed the X and Y motor shafts were slightly wobbling.

Lesson learned, new MK3's will get loose belts as much as i can get away with. Coupled with a third party toothed idler, this will work much better than the smooth idler the printer comes with.

May i ask what belt values you are getting after a printer calibration from the support submenu?

After power on make a printer calibration, i forgot if its XYZ calibration or selftest (most likely selftest), then go into support submenu and see belt statistics.

Prusa recommends a value of 240 +/-40.

Both X and Y are between 280 and 290 at their loosest functional point (i.e. self-test passes and yo can tell by wiggling the X or Y axis that there is a bit of slack but no dead gap.

I can't say that the belt reading are that accurate through. I have had belts report > 280 with pretty tight belts.

Re: Ghosting / Vibration Artifacts

Both X and Y are between 280 and 290 at their loosest functional point (i.e. self-test passes and yo can tell by wiggling the X or Y axis that there is a bit of slack but no dead gap.

I can't say that the belt reading are that accurate through. I have had belts report > 280 with pretty tight belts.

Hm I do think the same way but I never had an i3 design before. When I assembled it, I crosschecked the tension with my Flashforge Finder and the prusa was way thighter... but the numbers said around 270 😐

I still struggle a bit with the right tension. The description in the Build manual (pressing the belts together with two fingers / not slipping over gears / no slack) and the readouts for 240 +-40 really don't seem to match. I'm afraid I'd just break stuff when I aim for 240... But i really don't know. 😥

Re: Ghosting / Vibration Artifacts

My advice, print this belt tensioner for the Y-Axis and install it instead of the supplied one, https://www.thingiverse.com/thing:2786671 Tension the belt by feel and never look at the belt tension values in the menu again. If you suspect the belt is a little loose or a little tight you can quickly adjust to verify. Keep in mind that moire, ghosting and artifacts are likely due to something other than belt tension and we all experience it to some degree.

Re: Ghosting / Vibration Artifacts

honestly some of these issues may be belts themselves, maybe the supplier swapped types to save money and didn't say anything vs other machines.... there is a difference between a straight off ebay belt and a gates GT2 at the same belt tension.

The vertical artifacts could be more compression of the teeth so they squash when rolling over the idler and unsquish or pop back up when coming off, adding artifacts. lower quality belts could be worse. A toothed idler would help with this probably or just belt-flipping if there is room.

There is some Gates GT2 Belts on ebay too.