Extruder squeaking caused by PTFE tube?

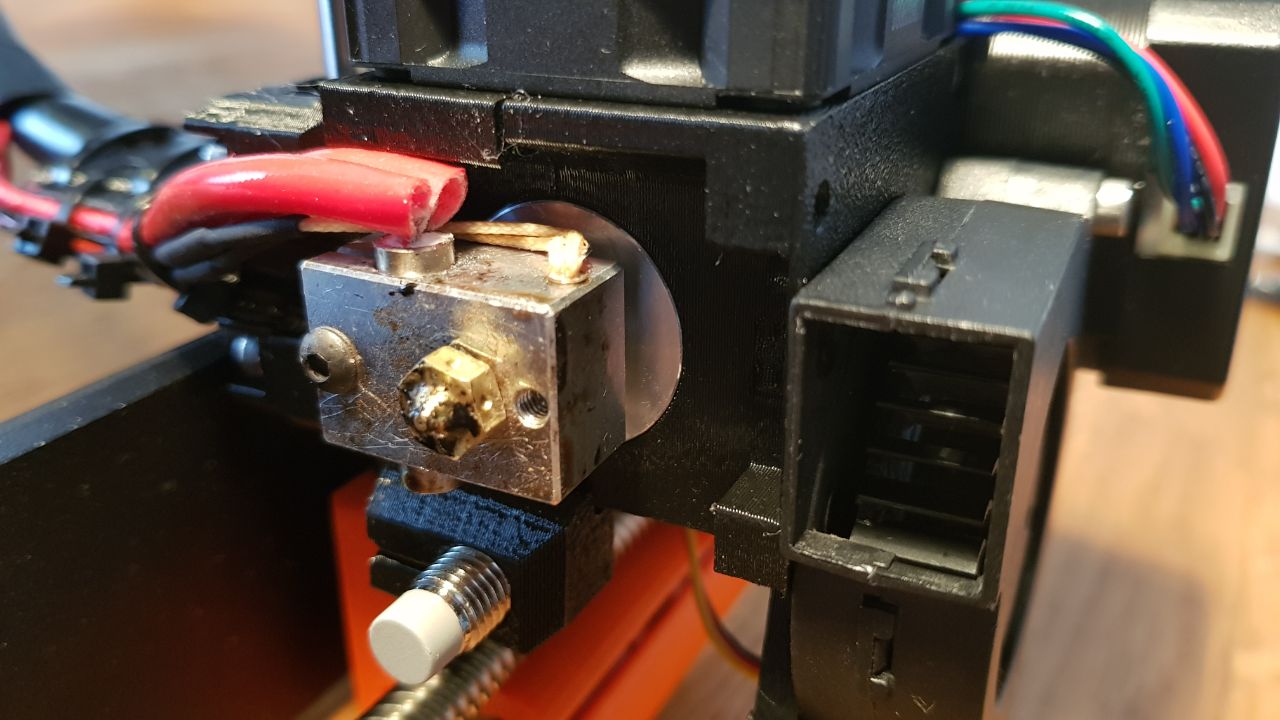

I just, out-of-the-blue, starting to get a squeaking noise coming from my extruder. So, I opened the idler door and noticed that the PTFE tube was touching the Bondtech gear.

I've attached a picture of the aforementioned. Could the proximity of the PTFE tube being too close to the gear cause this squeaking sound? Should I disassemble the E3D v6 hotend and trim the tube slightly? https://manual.prusa3d.com/Guide/How+to+trim+PTFE+tube+-+MK2-S+MK2.5+and+MK3/500#s8094

I also applied some grease to the teeth of the gears just in case that's the cause of the squeaking.

Re: Extruder squeaking caused by PTFE tube?

The PTFE tube is wrongly mounted and is too high up.

The lower section of the tefon tube (45 °) should be sealed to the hotend faced edge, so that molten filament can not penetrate the outside of the teflon tube.

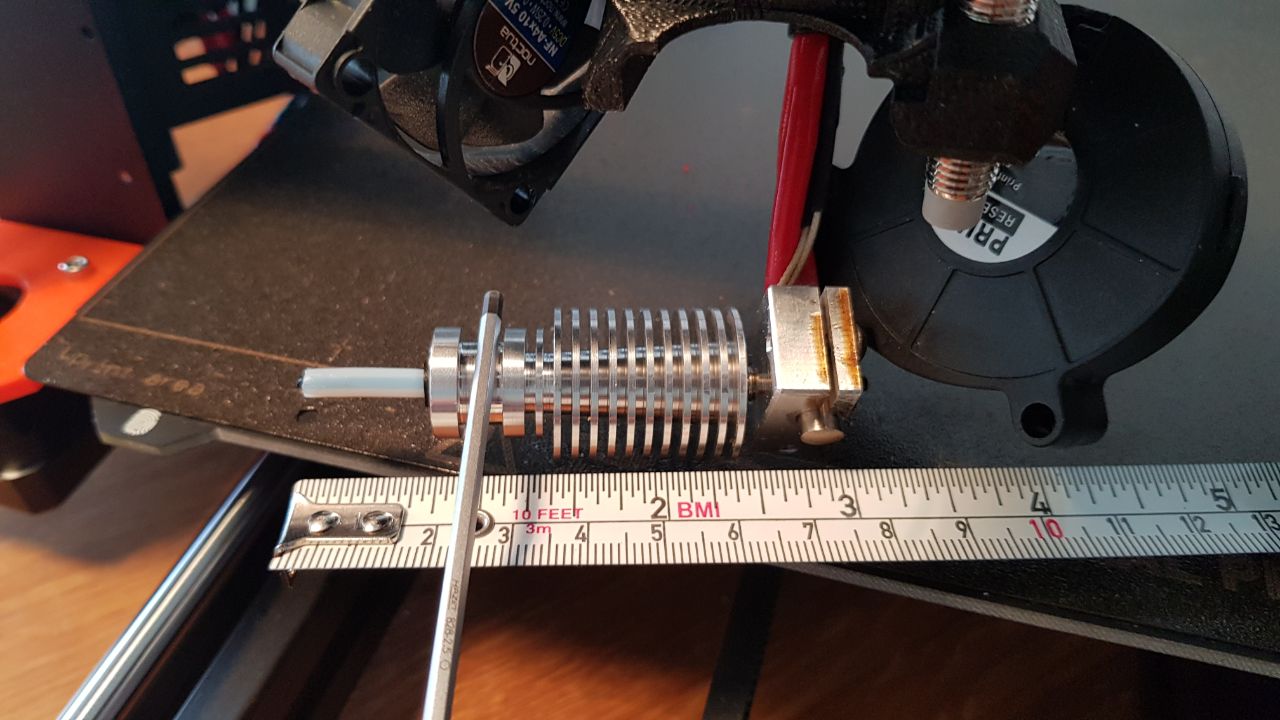

You must fix this and you should definitely not shorten the length of the PTFE tube. It should be exactly 50 mm long.

Bear MK3 with Bondtech extruder

Re: Extruder squeaking caused by PTFE tube?

Thanks for the quick reply. But, I'm not too sure how I'd go about fixing this.

The hotend appears to be mounted properly and is flush:

When I gently pull on the tubing, the black clip wiggles a little bit. But doesn't come out.

Re: Extruder squeaking caused by PTFE tube?

Hi Eric,

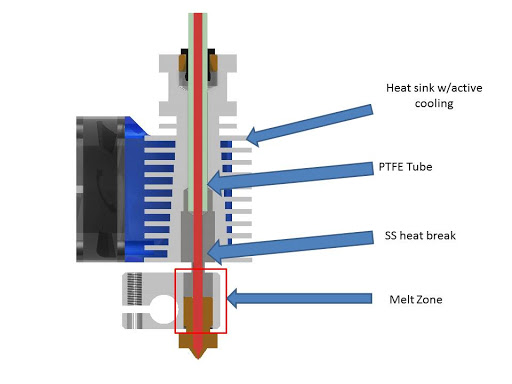

the attached picture is a generic E3D v6 cross section, Ignore the blue fan shroud and black fan

I suggest that you... Carefully, taking care not to damage the heater and particularly, the thermistor wires...

unscrew the heat sink, finned bit, from the heatbreak

the PTFE should stay in the finned bit, at this stage

if all is well, you should be able to press gently on the top of the PTFE Tube, above the black ring, and the PTFE tube should become visible at the bottom of the heatsink. pull the ptfe tube out of the bottom, put the heatsink down, carefully and admire your ptfe tube,

now compare it with the information and diagram here https://help.prusa3d.com/l/en/article/nt3gmt736i-ptfe-tubes-in-original-prusa-i-3-printers

it's now time for Audience Participation...

E3D say the bottom end of the tube should be cut square,

Prusa say the bottom of the tube should be trimmed/ chamfered at an angle of 45 degrees all round!

see what you already have and decide whether you want to follow the recommendations of your printer supplier, who have probably bought the greatest part of the E3D production volume or whether you want to follow the directions of the folk who designed the hot end in the first place...

Your choice...

I use the chamfered method... if you look at the picture above, you can see a small space between the end of the PTFE and the cup of the heatbreak, that the Prusa chamfered tube method fills...!

have a peep into the top of tour heatbreak tube and ensure there is no evidence of rubbish or old filament in the top of the heatbreak.

if there is junk or old plastic I suggest you clear it out!

now it's time to re assemble the parts....

E3d assemble them dry...

I assemble mine with a small amount of CPU heatsink paste on the 7mm heat break threads that screwinto the heatsink...(i'm a bit of a rebel...)

screw the heatsink all of the way onto the heatbreak, then unscrew the heatsink about half a turn

now, push the bottom of the PTFE tube into the black ring at the top of the heatsink, so that it seats firmly in the top of the heatbreak

(if you chose to use the square ended tube varient, you may have to jiggle the tube a bit to make sure it's properly inserted...)

(If you chose the chamfered end tube varient, it will slide smoothly into the top of the heatbreak 🙂 ... (Just sayin!... 😈 ))

at this stage keep one finger pressing on the top of the PTFE whilst lifting the black ring away from the heatsink.... you should be able to cause a small gap under the black ring (some folk put a C clip under the black ring to retain this gap.

now that the ptfe is firmly seated, tighten the heatsink against the heatbreak, taking care not to bend the heatbreak

now try pulling your PTFE, there should not be any slop, or free play...

reassemble your extruder assembly in the printer

Preheat the hot end, put some paper on youd build plate and load your preferred filament...

if you used heatsink paste it is likely that the first squirt of waste filament will flush out a bit of heatsink paste... the paper will stop that, contaminating your buildplate!

now check your live Z height as normal... (Jeff Jordan's "life adjust Z my way" https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html#p99776 version 6.1 files on the first page, are a good way of adjusting Live Z...)

and hopefully everything will be wonderful for you.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Extruder squeaking caused by PTFE tube?

Hi Joan,

Thanks for the detailed instructions!

I ordered some thermal paste, PTFE tubing, and a new black ring. I assume I'll only need the thermal paste, but I suppose it's good to have other parts on hand just in case.

I'll post a followup, with pictures, when the parts arrives and I'm done.

Re: Extruder squeaking caused by PTFE tube?

Thanks Eric.

Good luck

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Extruder squeaking caused by PTFE tube?

it's now time for Audience Participation...

E3D say the bottom end of the tube should be cut square,

Prusa say the bottom of the tube should be trimmed/ chamfered at an angle of 45 degrees all round!

I'm curious about this. I replaced my PTFE when I installed the R3 extruder parts. I noticed that since I've gone with the square end I haven't had anymore jams from letting the filament cool in the hotend. I've also noticed that after the hotend completely cools, I can pull the filament out if I open the extruder gear door (I don't have to heat the extruder at all). Could this be the cause for the change? If I want to do a cold pull I have to heat the extruder and then as it cools, continue pushing filament in by hand until it is too cool to melt. Only then can I get a good pull from the nozzle.