Extruder harness knocked tall parts off the bed

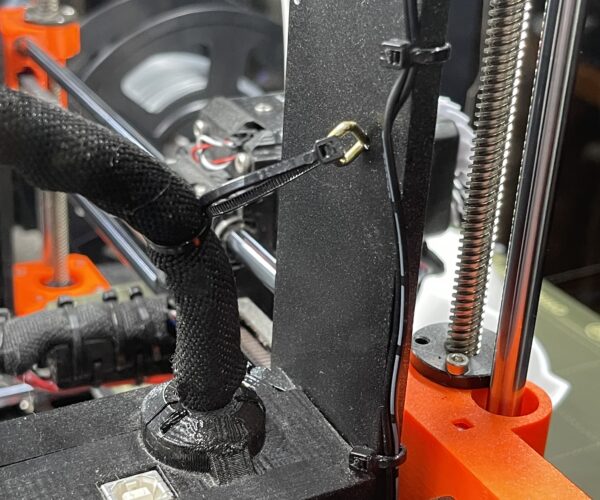

So I have two MK3S for over a year and never encountered this before. I print rocket models non stop. I recently made a Falcon Heavy model and that had the build plate quite full. The first print came out ok but had some unexplained layer shift about ¾ the way up on one part only. The next print was complete failure and had parts fall of the bed. The third print I happened to be right next to the printer when I heard the print start to get seperated from the bed. I noticed that the extruder cable droops below the parts in that corner and made contact with my model. This only happens when the parts are quite tall, the bad thing is that's 24 hours print time wasted. I took some pics of my "mod" and I hope this helps someone else in the future.

The eye hook is simply superglued into one of the factory holes in the gantry, and I used two tie wraps to keep the harness more vertical.

RE: Extruder harness knocked tall parts off the bed

Nice fix! I live your idea.

It looks like your Nylon Guide Filament has come loose, probably at the electronics box end.

See step 60 on:

https://help.prusa3d.com/guide/5-e-axis-assembly_169235

And steps 30, 32 on:

https://help.prusa3d.com/guide/8-electronics-assembly_174100

Cheerio,

RE: Extruder harness knocked tall parts off the bed

Nah, looked there first more likely my enclosure caused it to droop because of gravity and heat.

RE: Extruder harness knocked tall parts off the bed

I have the Mk3s now in an enclosure for more than 2 years and not seen any such drooping. What I have seen was the extruder cable drooping as the screw fixing the cable outrigger at the back of the extruder having come loose. Have you checked if that outrigger is sill firmly attached to the extruder?

What are your enclosure temperatures?

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Extruder harness knocked tall parts off the bed

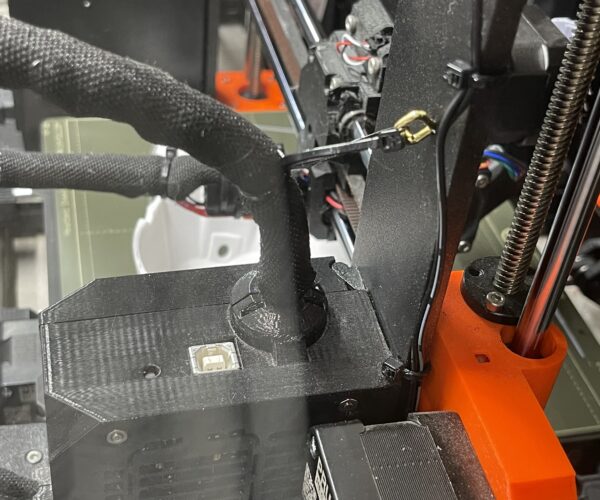

You appear to be missing a linear bearing on the Z axis.

RE: Extruder harness knocked tall parts off the bed

Really? How do you know?

RE: Extruder harness knocked tall parts off the bed

Really? How do you know?

Gaping hole in your X-end where the Z rod goes through it vertically. There should be two linear bearings in that hole and they should pretty much take up all the space there. Looks like you are either short a bearing, or maybe somebody substituted a single one of the longer version of the 8mm linear bearings, which are not as long as the 2 bearings end to end (the 2 bearings is the standard setup).

RE: Extruder harness knocked tall parts off the bed

I agree, my Z axis top bearing is flush with the top of the plastic.