Extruder clicking; very finicky idler screw adjustment

I have a MK3S (upgraded from a MK3), and lately the extruder has started clicking a lot. I've rebuilt and then completely replaced the hotend, made a new idler door and greased the bearings and gears, changed the nozzle, replaced the PTFE tube, recalibrated many times, replaced the Bondtech gears, and probably some other things I can't remember at the moment. It's incredibly frustrating.

Now I've been adjusting the screw for the idler door. I'm trying to find the most reliable number of turns to have the screw screwed in. I found a spot that worked ok, but wanted to keep testing. One turn out... clicking. One turn in... clicking. Half turn out... clicking. Half turn in... seems ok, but not sure yet (printing now).

RE: Extruder clicking; very finicky idler screw adjustment

This is absolutely maddening. I'm printing the same print over and over, and it will make it through it fine (no clicking) one time, then the next time it won't even finish the starter nozzle-clearing line without CLICK-CLICK-CLICK-CLICK. I don't understand what's changing.

I had another theory, that it might be temperature related (e.g. bad thermistor, bad heater, bad connections, bad thermal conductivity) and that unmelted filament was clogging, causing the gears to chew the filament, and then click. So I tried temp up, that didn't work.

If it starts clicking, I can unload/load the filament and keep printing. It will go some arbitrary time, and then click again. It always clicks once halfway through the starter nozzle-clearing line (where it suddenly jumps to a bigger width), and then as it picks up to start the perimeter line. Then, on these parts I'm making, if it clicks, it seems to almost always start clicking when filling in a wide flat area.

What am I missing? Nothing seems to have any lasting effect, or repeatable effect. Since it's started clicking, practically everything has been changed out... new hot end, nozzle, Bondtech gears, thermistor, idler door.

RE: Extruder clicking; very finicky idler screw adjustment

Hi Guido,

Could you try reducing your retractions to say 0.4mm

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Extruder clicking; very finicky idler screw adjustment

@joantabb

It didn't change anything. It made it 1/2 way through the first layer, then started clicking. I cleaned it and restarted, to double check, and it started clicking immediately (while making the nozzle clearing line in the bottom left).

RE: Extruder clicking; very finicky idler screw adjustment

Some progress, and potential progress...

I took apart the extruder, for the ump-teenth time, and discovered the Bondtech gear's set screw was a little loose. This would allow it to turn back and forth a little, on the motor shaft's flat. Interestingly, it would move to one side, then kind of get stuck, with the set screw wedged against the flat. The gear could be driven back and forth some, and it would stay fixed to the shaft because of the way the screw was wedged. Then, a more violent force would break it loose and it would wedge on the other side of the flat. This was very hard to detect.

Second, I was thinking more about problems that could cause the hotend to not have enough heat/energy to melt the filament, which would then cause temporary blockages. These possibilities could include loose connections, a partially damaged heat cartridge, etc. (It could also have been a 24V heat cartridge running on a 12V system, but I checked and this is a 24V system, so I ruled that one out.) Then I thought about how when I replaced the heatblock, which came in a full hotend kit, we broke one of the wires off the heat cartridge and had to use the new heat cartridge.

It turns out the heat cartridge that we installed was 30W, and the original is 40W. So that's a 25% reduction in available energy input.

I looked up the specific heat (energy required to raise a set amount of material by 1°), and it's 2137.108 J/kg °C for PLA, and 1470-1530 J/kg °C for PETG (we'll average that to 1500 J/kg °C). So PLA requires 40% more energy (per °C) than PETG. But PETG needs to be a little hotter to melt, so we need to correct for that.

Room temperature (of the spool) is about 22°C.

PLA:

215°C - 22°C = 193°C change

193°C change * 2137.108 J/kg °C = 412461.844 J/kg

PETG:

230°C - 22°C = 208°C change

208°C change * 1500 J/kg °C = 312000 J/kg

PETG / PLA: 312000 / 412461.44 = 75.64% ... a 25% reduction in energy input needed.

So I'm short 25% energy input, and haven't been having many problems with PETG because it needs 25% less energy. But as soon as I started trying to print PLA (which I never use, but someone gave me lately), which I foolishly assumed would require less energy because it runs at a lower temperature, it started clogging a lot, revealing my incorrect heater cartridge!

New 40W heater cartridge on order. We'll see if it fixes it. In the meantime, PETG is printing well again.

RE: Extruder clicking; very finicky idler screw adjustment

@guido-k

I noticed after my MK3S upgrade that the printer is much more touchy about the filament quality. I get no clicks whatsoever with Prusa and Prusament, a few here and there with Fillamentum and lots of problems with cheap filament (PLA). I relate it to the tolerances of the filament. Also have a look at the max. volumetric flowrate that your extruder can handle. You might just be pushing too much filament through. The standard 15mm^3/s for PLA is overly optimistic. I would set it to 11.5 and see how it goes. Last but not least, try to increase nozzle temp a bit. My sweet spot between stringing and too low a temp for Prusa filaments is around 208 ºC.

Regards

--

MK3

RE: Extruder clicking; very finicky idler screw adjustment

It will be a few days before the new heat cartridge shows up, so I am continue to research my hypothesis.

I tried slowing the print speed to 80%, still clicked.

Sped up to 110%, clicked.

Upped the head 10°C, clicked.

Tried printing at 0.30mm layer height... clicked.

0.20mm layer height... clicked.

Closing up the "photo studio tent" enclosure, to keep the filament warmer... clicked.

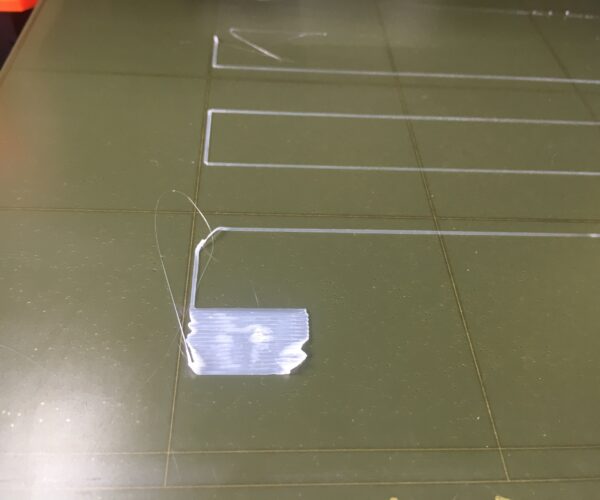

I started looking closely at the filament after unloading it. You can see in this picture that the last 5/16" toward the nozzle is always bulged out thicker (green arrow). I checked some older spools of filament I have around, that were unloaded long before I was having these problems, and they do not have this bulged area.

I also looked carefully at the kinked area where the gears are engaging the filament when this clicking happens (blue arrow), and it actually doesn't look like the gears have chewed off the side of the filament. There are very clean teeth marks on both sides of the filament, but no cutting.

So could the 30W heat cartridge be causing this? It seems like the filament is getting hot/soft higher up, and not being able to go through as fast as it's being pushed, so it gets bulged up, and then is really stuck. Once it's really stuck, the gears can't drive it through, and click. With some of those thing I tried (e.g. slower, less layer height, higher temp, etc.), if it was just the heat cartridge not keeping up before, shouldn't it have been able to now?

I wish Prusa just sold a $200 whole new extruder, and I'd be done screwing with it and back to printing. This damn problem has now takes dozens of hours of time, and a couple hundred dollars in parts, and is not any further along.

RE: Extruder clicking; very finicky idler screw adjustment

Hi Guido-k

Sorry cannot advise much but my story resembles yours a lot (but I have not yet replaced half of the hot end 🙂 )

RE: Extruder clicking; very finicky idler screw adjustment

Judging from your middle picture it looks like your first layer calibration is way too close to the bed so you get that rippling effect in your calibration square, i suggest you redo your first layer calibration.

And remember, any time you take apart the extruder or adjust the pinda probe, the calibration will be wrong and you need to redo it and the values you get may not be the same or similar as you had last time.

Also remember to clean your bed with IPA to remove any grease and fingerprints.

RE: Extruder clicking; very finicky idler screw adjustment

Not sure if this help, but I'll suggest it anyway, just in case.

Could you maybe try printing at an even higher temperature? The MK3S heatbreak has a 2.2mm inner diameter (to help with the MMU2 upgrade) as opposed to the usual 2mm, and that can cause some extrusion issues with some filaments when they solidify in the area of that 0.2mm lip. According to protopasta it help to either slightly oil the filament or print their PLA at 240°C.

One other thing you could try, if the budget allows: Investing in a bmg extruder with a 3:1 gear ratio. that should greatly increase torque.

RE: Extruder clicking; very finicky idler screw adjustment

Surely The BMG torque is only useful if the current extruder is not chewing up the filament, at the bondech gears, the filament is the limiting factor. both extruders use the same drive gears

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Extruder clicking; very finicky idler screw adjustment

@joantabb

Very true, but with more torque more spring tension is an option.

RE: Extruder clicking; very finicky idler screw adjustment

@alex-s24

Wash bed with dish soap (after this it sticks the best), every few prints, and with filament change.

Do the live z-calibration, you need to go higher, a little.

RE: Extruder clicking; very finicky idler screw adjustment

@torbjorn-j3

Thank you for your reply

Will play with calibration again. I have never taken apart the extruder (yet) but aware of the need for calibration.

Yes I do clean with IPA though may be less lately

RE: Extruder clicking; very finicky idler screw adjustment

@chaos-the-5th

Thank you Chaos for your reply

Yes I actually managed to achieve better adherence on 240-250 C for PLA but felt it is quite inconvenient to wait till end of calibration, then increase the temp and reduce the speed to 85-90% just to come back in 3-5 min again to check the adhesion. I know we are at the dawn of 3d printing and have to check the newly discovered wheel very often but still.

I feel Bondtech gears are ok, the autopsy of the cold pulled filament showed good traction (by toothed corrugations). I am still not sure how much to torque the screws in the idler.

RE: Extruder clicking; very finicky idler screw adjustment

@peter-m26

Thank you mate, did not think of dish washing liquid. Will definitely try.

RE: Extruder clicking; very finicky idler screw adjustment

I have similar problems.

This helped me: https://help.prusa3d.com/en/article/extrusion-problems-prevention_2027

I have changed the E3d heatbreak and added heatsink to extruder motor but not much help.

Recent two changes did help:

1. When re-tighten the heatsink and the nozzle to the heatblock (at 280C), make sure there is a gap (about 0.5mm) between the nozzle and the heatblock. (before that my nozzle touched the heatblock completely). Technically speaking, I did a cold pull to clean the nozzle first, then I turn loose the nozzle next, then tighten the heatbreak, then tighten the nozzle finally. There should be a gap. Be careful, all things are very hot.

2. Tighten (yes, tighten, not loosen) the idle screw as described above in the troubleshooting guide."...The head of the idler screw should be aligned with the Extruder Body (see the photos above), when filament is loaded." Previously mine was too loose because I wanted to prevent extruder motor overheat. Now my extruder motor is still overheat, but there is no more jam when printing PLA.

Not sure what help me can help you, but I think there is no harm trying. Good luck.

RE: Extruder clicking; very finicky idler screw adjustment

I'm on the Powder Coated sheet and I have been pouring over these threads for the last week or so as I'm having bed adhesion AND extruder clicking issues printing simple flat ear savers for face masks. About half the time the extruder would start clicking on the first layer or the part would curl up from the bed later on in the print or come completely detached. But I think I made progress today after pretty much checking everything else I could find in these forums .

I changed the mesh setting to 7x7 and 5X per spot.

I have multiples of these parts across the bed so I think what was happening was two fold: 1. The powder coated sheets requires a much more "squished" first layer to maintain adhesion and uniform look 2. More squished = closer to bed therefore less room for error in bed levelness. So as the nozzle moves across the bed it's getting "clogged" against the bed in some areas (clicking issue) and too far from the sheet in others (adhesion issue).

Once I upped the setting to 7x7 I was surprised how much the z-axis moved as it traversed the bed for the first layer. It's not a lot (motor maybe spins 5 to 10 degrees) but definitely visible to the naked eye. The first few prints with the new settings have started and they look MUCH better on the first layer and no more clicking or adhesion problems... yet.

I thought I'd share as I'm not seeing anyone else any where mention trying this.