RE: Drying Times and Temps in Dehydrator

It could be that as PETG is just stringier than PLA in general, so it may be more sensitive to moisture content levels Vs. PLA before print defects appear? I still have no idea the ideal moisture content level should be... <0.1%, 0.2% etc.? Anyway, I think this test is going to turn out to be pretty dull. From the observations I've seen mucking around on my other samples, I expect it is going to be pretty quick and easy to (store &) knock down the moisture level of PETG and PLA to a "good enough" moisture level for printing.... the exception looks like ePA-CF (that one I expect will be harder).

RE: Drying Times and Temps in Dehydrator

Snagged a really sweet Cabelas 12 tray Dehydrator that was in the clearance section for $55. Dry filament here we come!!! Now I just need to print some supports for the inside!

No problem can withstand the constant assault of persistent thinking - Voltaire

RE: Drying Times and Temps in Dehydrator

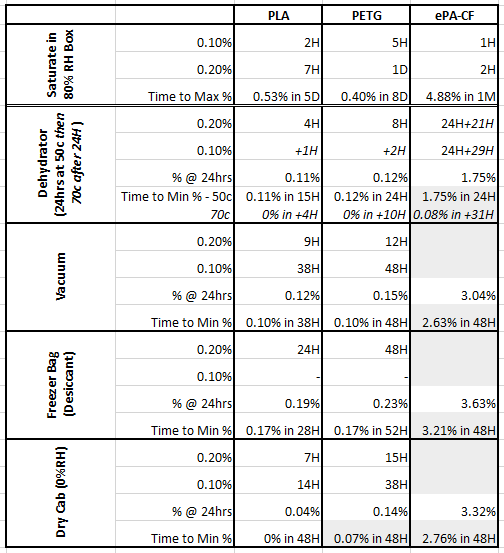

After 6 weeks in the 80% Humidity Box, I've started the Drying Tests on my filament samples. I'm only 24hrs in so the items greyed out are not yet recorded.

- Row 1: This shows how many Hours / Days / Months it took for the samples to gain 0.1% / 0.2% / and then to reach it Max %

- Other Rows: This shows how many Hours / Days / Months it takes for the sample to get back to 0.2% / 0.1% / and then to reach it's Min %.

I'll add some more commentary after more time running the tests.

Thanks

Nathan

RE: Drying Times and Temps in Dehydrator

Next set of results. As I'm running out of time before I have to travel for work, I increased the temp in the Dehumidifier from 50 to 70c. I will get one more post in prior to leaving with some commentary, but for now here is some Notes I've been taking of my observations so far:

- PLA is quick and easy to dry but will get "damp" in as little as 7 Hours

- PETG takes longer to dry but will get "damp" in as little as a 1 Day

- ePA-CF is much harder to dry (takes days) and gets "damp" in as little as 2 hours

- Food Dehydrator at 50c will dry down to around 10%

- Food Dehydrator at 70c will dry down to 0% and is much quicker (but this temp is deemed too high for PLA and PETG as it is above their Glass Transition Temp)

- Vacuum will dry down to around 0.10%

- Freezer Bag will dry down to around 0.17%

- Dry Cab (0%RH) will dry down to 0%

- Store and Print filaments in as low a RH environment as possible (eg Dry Box for storage and print from a Dehydrator)

- Filament moisture content goes up and down with RH

RE: Drying Times and Temps in Dehydrator

Sorry - the numbers are meaningless until the actual weights involved are shown. I still do not trust the "dry first to establish moisture baseline" and the resulting math to calculate percentages remaining are just massive assumption errors waiting to happen.

You, as a consumer, can't know what the moisture content of a material is. You can guess, but you can't measure. Even plastic manufacturers have issues measuring moisture content, and they spend lots of money trying to determine the number.

Think of the issue this way: At what temperature does water (in any form) completely dissipate? Yes, there is H2O in the sun.

RE: Drying Times and Temps in Dehydrator

C'mon, I spent a bunch of time and effort on this and even got the professional OHAUS 0.001g scale 🙁 . + you have always had access to the raw data if you want to look at the numbers and so here is the link to the spreadsheet again https://jmone.org/jmonenextcloud/index.php/s/GKoJEmayEaBCRNG .

Anyway, I was interested to see:

1) How long and by how much the filaments would gain weight (thanks for how to make a simple 80%RH box for this)

2) How long and by how much the filaments would lose weight using various methods and how close they would get back to the starting point (or if they would even make them "drier")

I then expressed these as a % but the weights are in the spreadsheet.

Of course, I have no idea what the actual moisture content of the filaments are when I started but all the filaments had been stored for an extended time in my 0%RH Cabinet and even the Dehyrator running at 70% only brought the PLA and PETG back to around the same starting value and that was after days. So for practical purposes this is as dry as we can get filament in a domestic setup. I guess if you purchased a Moisture Analyser with the same resolution you could test what % they still had 🙂

To me the "real" question that has still gone unanswered is what is the target moisture level before we start to see printing issues. It's all well and good to know how much a filament gains, or how much and how long to it takes before it gets no drier, but what is "good enough" for our purposes.

Thanks

Nathan

PS - I'm still to write this up (including the method) but is there any of the "observations" made in my prior post that you have an issue with?

RE: Drying Times and Temps in Dehydrator

Snagged a really sweet Cabelas 12 tray Dehydrator that was in the clearance section for $55. Dry filament here we come!!! Now I just need to print some supports for the inside!

Looks like that unit normally goes for something like $170. Good find. Was it a Black Friday sale?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying Times and Temps in Dehydrator

[...] To me the "real" question that has still gone unanswered is what is the target moisture level before we start to see printing issues. It's all well and good to know how much a filament gains, or how much and how long to it takes before it gets no drier, but what is "good enough" for our purposes.

Even if the results don't yield the results you expect, I'm enjoying looking over your data & graphs. If nothing else, you've put more together in one place than I've seen elsewhere, at least in terms useful to the hobbyist. The PETG results are a surprise, and I'd like to see other testing.

Drying filament became the rage last year and the flow of information on basic storage and handling has definitely been a net positive. For some filament types, "moisture absorption" is definitely a concern. I'm increasingly convinced, though, that there are other issues related to moisture and relative humidity, and that absorption is only one of them. I base this on my experience with PLA over the holidays in which the stringiness of PLA varied significantly day-by-day with the extreme variations we experienced in December. Those pics show a significant swing with Paramount PLA when things got wet towards the end of the month. Whether it be due to moisture in the air, moisture on the filament or perhaps some other environment factor that is being overlooked, drying fixes common problems with stringing. While PLA certainly doesn't appear to absorb a significant amount of moisture, variations in RH certainly seem to do something to the FFF printed result.

This is going to be a challenge simply because of the varying conditions we print in. My experience in Phoenix will be different than Houston or Boston, and those will vary day-by-day. If nothing else, your data may help eliminate some considerations. Now if only you could spit out a test print with each sample when measuring...

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying Times and Temps in Dehydrator

@Bobstro - thanks!

FWIW - We know that the filaments will both gain and drop weight in line with changes in RH. PLA can pick up significant moisture in just a few hours (sits between PETG and PA for how quickly it hydrates). So if you are printing during a higher that normal humidity period, you filament will gain moisture and at some point it could be "damp" enough where you start to see print issues (like stringing). When the humidity lowers, the filament will become drier. To your point, it would be interesting to print a string test model (they are quick and use little filament) at various moisture levels..... but I think I'm almost done!

RE: Drying Times and Temps in Dehydrator

....except I'll let the ePA-CF samples in the Dry Cab and the Freezer Bag go for a few weeks to see where they stabize at. The rest of the samples I'm leaving in covered by exposed to the atmosphere in rear my printer to see where they all end up in a "normal" home environment.

RE: Drying Times and Temps in Dehydrator

I can buy into PLA filament absorbing moisture over 24-48 hours (though your data seems to indicate not a lot), but losing that absorbed moisture in the same period in otherwise unchanged conditions is hard to accept, at least based on my understanding of the issue.

RH almost certainly has to be a factor since my temps and printer were otherwise unchanged. I would expect any moisture on the surface to cook off in the hotend almost immediately.

Your data has certainly got me looking at this differently, even if from an unscientific angle.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying Times and Temps in Dehydrator

Final thought: Would love to seal up an enclosure and print samples at various levels of RH in controlled circumstances. Alas, work makes that impossible for me.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying Times and Temps in Dehydrator

Nathan, there is definitely lots of effort in your work. And no - I had not seen you raw data link before this. My main concern is that subtle mistakes in measurements, or how results are interpreted. Many great experiments have been ruined by assumptions made in the data reduction phase. Years of experience looking at data that leads some to one place based on prior perception has trained me to be cautious. The raw data is there in the spreadsheets, but just how it is being normalized is a question I have, and a few things look odd.

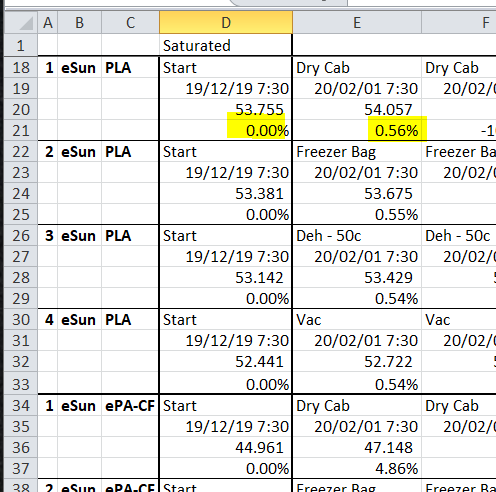

Here's an example that might be clear to you, but confuses the heck out of me. If the test in D20 started with saturated PLA, then why is the sample E20 heavier after a few days when you start drying? I can guess you meant the D20 value is the dry unsaturated value... but that isn't what you wrote.

RE: Drying Times and Temps in Dehydrator

I've removed the D1 Comment, but FYI it was a comment for me that info in that Col was copied from the "Saturate" (the 2nd) tab and the Values are the "Start" on that tab (eg the "dry" values). Feel free to ask any Q's you have as it will help when doing the final write up. I'm sure there may be actual data errors as well (I've found a few from poor data entry on my part entering the data from my handwritten data sheets) so if you see something that looks bad I can go back to the notes.

RE: Drying Times and Temps in Dehydrator

....and the dates are all yy/mm/dd HH:MM so the D col is some 6 weeks before the start of the drying. You want to look at the two tabs, "Filament Test (Saturate)" is the samples gaining weight in the Humidity Box, and "Filament Test (Dry)" is how they dry out.

RE: Drying Times and Temps in Dehydrator

Just to be clear, the first column is the wet weight, taken from the Saturated worksheet?

Call me triple confused ...

RE: Drying Times and Temps in Dehydrator

I finally figured out your logic ...

Still absorbing the results. Initial thought for PLA is e-Sun doesn't absorb as much water as all of the brands I've tested.

Kudos for all of the effort in making the experiments - great information to ponder.

RE: Drying Times and Temps in Dehydrator

Did some data reduction and came up with this: I think it asks more questions that it answers ...

RE: Drying Times and Temps in Dehydrator

The things I'm interested in:

- How much moisture various types of filament absorb?

- How long do various drying methods take to restore filament to the original weight (level)?

As long as the various samples start with some baseline (e.g. dried at recommended temp and duration using X criteria) I'm plenty happy. I'm also very interested to see if "drying in a freezer bag with desiccant" is effective. I always assumed it would not be, but it does sound like it can help more than I expected.

I may pull the spreadsheet down to play with next time I'm stuck on a long flight. Good stuff to have available.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying Times and Temps in Dehydrator

What I found for my filament was moisture removal in PLA was much faster: and I started with a heavier saturation of 0.752% by weight. Time axis is in hours.

I do have another test on-going, but was rather surprise soaking in water appears to double or even triple the water absorption. I am trying to normalize the test to see if that is true - samples are now both in an 80% chamber for a week, and if the wet sample starts drying then I can almost accept soaking increases depth of saturation over air at 100% RH (my saturation phase was started Dec 06, 2019, so the two parts had plenty of time to soak up water). There's also a chance my printed test parts have crannies that held liquid water... the soak at 80% should dry those spots out.

ps: Science is fun ... good science, not so much.