RE: Drying Times and Temps in Dehydrator

I also have some data for gain and loss of ePA-CF, again don't take much notice as this is using some 3D Printed Spanners I was doing torque testing on and again using my old balance. But you can see that after almost 3 weeks in Atmo, the ePA-CF gained 3% and the best method was a combination of Heat and Vac rather than just Vac (I only had two samples so no Heat Only). I gave up before either got back to the initial print weight.

RE: Drying Times and Temps in Dehydrator

So my 1.8% (ish) looks to be in line with the NIST?

RE: Drying Times and Temps in Dehydrator

Eh, not really. NIST reached maybe 1.5% while the PLA was disintegrating at 60c ... but who knows which compounds were being used. And color. It's known dyes make a difference.

I have a couple samples of European Banana Yellow filament I'm going to immerse and put into 100% ... but one sample keeps changing it's weight on me by 10 grams. I suspect electrostatic cling is affecting my measurements since the weight changes that 10 grams if I simply invert the piece... lol. Need to get my anti-stat gun out. lol. Measurements are never easy.

RE: Drying Times and Temps in Dehydrator

Coloured filaments will usually contain Titanium Dioxide which itself can absorb moisture and depending on the manufacturing environment and how it was stored, bring moisture into the filament during manufacture.

If you really want to create unadulterated baseline absorption / drying tables, then maybe you should consider natural uncoloured filament since the deeper and or brighter the colour, the more TiO2 it is likely to have in it.

Whether it has any affect being bound in a polymer on absorbency of water I have no idea, but just something to consider.

I suspect European Banana Yellow may have a fair amount of TiO2 in it.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Drying Times and Temps in Dehydrator

Coloured filaments will usually contain Titanium Dioxide which ...

Um - yeah, but Titanium Dioxide is the primary pigment in White -- because TiO2 is white. Lol. And this material is not hygroscopic. While an opaquing factor is some colors, white will generally have the highest concentration. Other chemistry of PLA is likely responsible for the differences in absorption rates. What one article said was surprising: that blue pigment was the worst. But that article was also a bit shaky by not saying if the blue was the same composition or even from the same manufacturer as the white and black it was tested against.

Titanium dioxide, commonly known as titanium white, is in normal conditions a colourless crystalline solid. It is non-toxic, non-hygroscopic, inflammable and non-volatile. ... Titanium dioxide occurs in nature in three polymorphous varieties: tetragonal rutile, anatase and rhombic brookite.Jul 26, 2017

As for my Banana Yellow - it is a European color purchased from Prusa. The same as the other highly pigmented filaments I've received from them. So yes, I agree with @chocki it has plenty of TiO2 - though it doesn't pile up quite like the Beige color of that brand.

I should also test my Filacube PLA2 -- which btw prints amazingly well for inexpensive filament. I've seen it resists thermal warping quite well compared to other PLA like my Prusa Orange look-a-like.

...

On the testing side, seems like every time I touch my newest test parts they gain 5 milligrams... lol. My fingers must really be putting out the oils.

RE: Drying Times and Temps in Dehydrator

Most likely drift on that scale as apparently fingerprints are in the Microgram not Milligram range.

http://stateoftheunit.com/blog/2018-04-10_MassFingerprint.shtml

Dispelling the myth," Forensic Science International 266 (2016) p. 134–138. http://dx.doi.org/10.1016/j.forsciint.2016.05.016

The paper's author Terry Kent says it's hard to get precise numbers because of so many factors, but the estimates from other experiments average about 4 micrograms of stuff, including fats, salts, and at most 20% water. And according to author's own experiments, fingerprints could be 10 times the average, which would be about 40 micrograms.

I'm liking the my new scale! Nice and stable, zero it, plonk down a sample and it is repeatable with variation of 0.001g at most, which on the 25-30g samples is fine. Only downside is a scales like these are expensive.

RE: Drying Times and Temps in Dehydrator

FWIW, quick interim measurement this morning on the samples to see how they are gaining: Atmo / Humidity Chamber / Water

PLA: 0.10% / 0.44% / 1.23%

ePA-CF: 0.68% / 2.03% / 12.85%

--------------------

The ePA-CF is a sponge! The RH overnight in my room was between 47-58% and even the ePA-CF in Atmo for 8hours gained enough moisture to start to be a problem as it is already 0.68% (Dupont recommend <=0.2% for their PA66). I'll be interested to see how the all go when I'm back in 5 days.

RE: Drying Times and Temps in Dehydrator

Deep dives and over-application of technology is good fun, but unless you plan to test every filament you use, won't it be nearly impossible to develop much more than general guidelines? I'd expect the spool design, even the amount of filament remaining to throw a lot of fuzz into the numbers. Is neatly coiled filament going to take longer than the same stuff wound more loosely?

I'm wondering if it will be possible to get much more accurate than "toast it for a few hours".

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying Times and Temps in Dehydrator

That I do not trust the immersion method is a known (or should be known) factor. No way to verify all the attached water has been removed, and the water that is adhering rather than absorbed is going to be a huge fraction of the number: like 12% huge. Nylon 6 immersed takes 30 days to absorb 10% it's weight in water. I simply do not believe 12% in 24 hours: and toss it aside as a measurement error. Water is trapped in the print crevices and some is still wetting the outside surface.

@bobstro -- yes - my tests were to confirm or invalidate using a simple vacuum pump and air dryer to keep PLA moisture levels constrained. Air drying won my tests hands down over vacuum: with 4 hours of heat adequate to remove 80% of the moisture; and 8 hours sufficient to remove 95% from one brand of PLA. Vacuum only achieved 65% removal in 8 hours.

RE: Drying Times and Temps in Dehydrator

This is starting to remind me of Douglas Adams.

"What about this wheel thingy? It sounds a terribly interesting project."

"Ah," said the marketing girl, "Well, we're having a little difficulty there."

"Difficulty?" exclaimed Ford.

"Difficulty? What do you mean, difficulty? It's the single simplest machine in the entire Universe!"The marketing girl soured him with a look.

"Alright, Mr. Wiseguy," she said, "if you're so clever, you tell us what colour it should be."

RE: Drying Times and Temps in Dehydrator

"It is a ferocious beast, fangs as long as your arms, hideous, and ..."

"But it's just a furry little bunny rabbit."

RE: Drying Times and Temps in Dehydrator

FWIW, another interim measurement this morning on the samples to see how they are gaining after 5 days: Atmo / Humidity Chamber / Water (note: I took them out of the water last night and dried these samples multiple times with a lint free cloth and left them in Atmo for 12 hours so they are dry to the touch & My Atmo as been on average 25c / 50-60%RH over the last week).

PLA: 0.22% / 0.71% / 0.66%

ePA-CF: 2.66% / 7.42% / 10.75%

It looking at some of my other spot measurements, it seems the PLA is stabilising around a max gain of about 0.7% (it has stopped gaining weight in the high RH box and the soaked sample left overnight in Atmo has pulled back to a similar % gain). The ePA-CF is still absorbing moisture in both Atmo and the high RH box, but again the soaked sample left overnight has pulled back and if I was to guess they will end up around 10% ish.

It is interesting (but I guess not surprising), that it looks like ePA-CF absorbed as much water in 8hrs (in Atmo) as PLA does all up.

RE: Drying Times and Temps in Dehydrator

Thanks everyone for your time and dedication to finding out just how much of an issue moisture absorption can be.

Whilst I'm not doing much (any recently!) printing ATM (SWMBO wants the house done up), your findings make me think that filament really does need drying before use, especially if you have had a hiatus from printing, and zip lock bags are just not good enough.

I keep my opened filaments in a clip lock box with bags of silica gel, which helps keep the moisture down, but even this will only extend the time between drying, and some filaments ePA-CF look like they would benefit from being kept in a dry enclosure even during printing.

I have never actually used ePA-CF yet, so maybe someone whom has and has done some long prints >12 Hrs, is there any noticeable difference between start and end of printing which could warrant keeping this filament in a dry enclosure during printing?.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Drying Times and Temps in Dehydrator

I just wanted to chime in and say I appreciate y’all taking a dive in to this. Great to see some amateur sleuthing going on

Ive been printing for a little over a year now and have had moisture issues living in the Midwest. I have a cheap food dehydrator that I toast my filament with. I’ve used pla, petg, wood filled, metal filled, and Taulman bridge. Nylon seems to be the thirstiest, especially self dyed nylon.

Keep up the sciencing. I appreciate it.

RE: Drying Times and Temps in Dehydrator

Another 24 hours on, and samples in water that are now in Atmo (still 50-60%RH) continue to dry out and are now lower than those still in the 100% humidity box. Atmo / Humidity Chamber / Water (now Atmo)

PLA: 0.22% (no change for 60 hours) / 0.71% (no change for 60 hours) / 0.50% (still dropping)

ePA-CF: 2.66% (no change for 24 hours) / 7.60% (still gaining slowly) / 7.04% (still dropping)

If it keeps going that way, it would appear that:

- PLA will gain between 0.2% (in 50% RH) and 0.7% (in 100% RH).

- ePA-CF will gain between 2.5% (in 50% RH) and 7.5%? (in 100% RH)

If it stabilises at these figures then it would suggest that moisture absorption in PLA (eSun PLA+ White) is only going to be an issue if you are in a Humid Environment, and that ePA-CF (eSun) will always need to be kept dry. I've now also added PETG (eSun White) to the sample set being tested.

I have never actually used ePA-CF yet, so maybe someone whom has and has done some long prints >12 Hrs, is there any noticeable difference between start and end of printing which could warrant keeping this filament in a dry enclosure during printing?

I've done a 18h ePA-CF prints but I did print direct from my dehydrator running at 70c. In this setup I had no issues.

RE: Drying Times and Temps in Dehydrator

I'm now starting the drying part on the first of the PLA and ePA-CF samples (the ones that have stabilised in Atmo @ PLA = 0.21% and ePA-CF = 2.64%). These two I've now placed in my Ultra Low Cabinet (reads 0% RH). Lets see how these dry out (I expect it will take some time).

I've also moved my PLA and ePA-CF samples from the 100% Humidity Box to Atmo as these too have stopped gaining weight at PLA = 0.71% and ePA-CF = 7.66%. In line with the samples in water moved to Atmo, I expect both to fall in Atmo and will then will test these in both the Dehydrator and in Vacuum once stabilised.

I've also now added samples using ePC (and prior to that PETG).

RE: Drying Times and Temps in Dehydrator

I'm also going to start drying a PLA sample in the Dehydrator (the one in water, then in Atmo) as it has stabilised at 0.49%. I'm going to warm the dehydrator up to 50c (print dry recommendation) for 30min then put the sample in a measure how it goes.

RE: Drying Times and Temps in Dehydrator

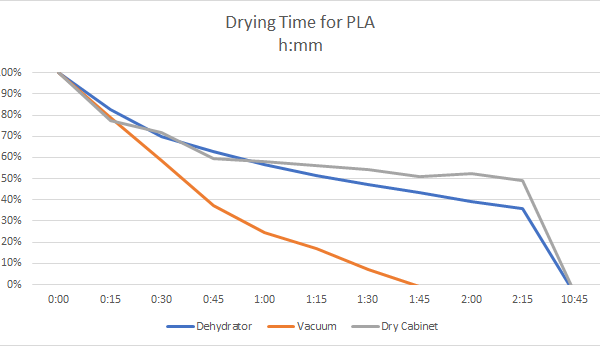

PLA (eSun White) results are in. This shows how quickly each sample regained it's printed weight using various drying methods:

- Sample 1: Dehydrator was at 50c: Sample used had gained 0.37% since printed (soaked in water for 5 days then left in Atmo for 36 hours before drying)

- Sample 2: Vacuum was strong enough to boil water and the vacuum chamber was on a heated plate keeping the samples inside around 35-40c: Sample used had gained 0.42% since printed (left in a 100% RH box for a week then left in Atmo for 12 hours before drying)

- Sample 3: Dry Cabinet reads 0%RH: Sample used had gained 0.21% since printed (left in Atmo @ 50-60% RH for a week before drying)

My (unscientific) thoughts so far are:

- Any method will dry out PLA successfully,

- PLA really does not absorb that much moisture to start with, so drying it out is relatively quick and easy (if even needed),

- All three methods work by creating a lower RH environment than the sample allowing migration of moisture to the Air, and

- The warmer the sample, the quicker the transfer seems to be.

Thanks

Nathan

PS - the ePA-CF tests are running now.

RE: Drying Times and Temps in Dehydrator

The data is very misleading; almost like you had a specific outcome planned - that vacuum works best - by conflating vacuum with heat. Plus, in earlier posts you claimed PLA immersed in water had gained 1.2%, then later reported only 0.66%, and then used the driest sample for vacuum, and the wettest sample for the dehydrator. And you have no control.

You've proven again that poorly designed experiments yield dubious results.