RE: Drying Times and Temps in Dehydrator

Would I be right in saying that I think we can also safely say that the best filament drying method for a reasonable cost is a food dehydrator ?, I'm sure with enough vacuum you could also get the moisture level down further, but at how much expense?. the dehydrator also appears to be quickest initially, but I am surprised that a drying cabinet with no additional heat can be as effective!.

Which then leads me to ask, what if the air for the dehydrator is first passed through a desiccant filter to remove moisture before heating, how much quicker would this dry the filament?, probably not worth the extra cost and energy to dry the desiccant first.

Or we all just move to Death Valley!. No issues with humidity there! - Heat creep could be an issue though 🙂

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Drying Times and Temps in Dehydrator

For anyone reading this thread and wondering about storage, I keep my filaments in a Lock & Lock 12 L box with a few bags of desiccant inside.

I Kg rolls fit side by side 4 or 5 depending on width of reels leaving room to put some bags of desiccant in as well. The boxes have a top handle to make it easy to lift, and stack nicely.

I have not been able to use my printer for nearly 2 months due to building work at home (UK damp winter!) and finally did a print last night, just grabbed a part reel of PET-G from one of my L&L boxes, cleaned and lubricated the printer, loaded the filament and printed perfectly without any signs of moisture absorption by the filament.

This filament had been dried previously in a cheap £27 OYPLA brand dehydrator which I also use for drying the desiccant. Well worth the cost, this particular dryer has removeable trays which means you can stack 2 or 3 rolls of filament inside.

https://www.amazon.co.uk/s?k=dehydrator+oypla&ref=nb_sb_noss_2

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Drying Times and Temps in Dehydrator

New chart: shows dehydrator vs vacuum. After 8 hours, I swapped samples: dehydrator went to vacuum, vacuum to dehydrator. Continued drying for 8 more hours and recorded weights. Then moved samples to oven for another higher temp dry, recorded weights. Dehydrator is much better than vacuum for my generic PLA samples. Expand the view to see everything.

RE: Drying Times and Temps in Dehydrator

I'm back from my work trip so I can continue the discussion. One point worth bringing out is "How Quickly" does filament absorb moisture in the environment and how quickly does it lose. Here is a chart of PLA over 8hrs:

- in the 80% RH box: it gained 64% of all the weight it would ever gain in just 8 hours

- In the Deh and Vac: It lost 69% of all the weight it had gained in just 8 hours

- The Deh is much quicker than Vac in driving out the weight gain (it got rid of 30% in just one hour vs 20% for the Vac)

The point I see, is that filament will gain a surprising amount of moisture content in a relatively short amount of time. If you are printing in a humid environment, it really is best to not only store the filament in a dry box but to also print from a modified dehydrator to keep the filament dry while printing.

RE: Drying Times and Temps in Dehydrator

Notes on how I Saturated / Dried the Samples (this will be mostly for Tim to tell me I've stuffed it up 🙂 ):

Saturation: Used a plastic airtight container to hold 4 x eSun PLA+, PETG, ePA-CF 50gram (ish) raw filament samples wound tightly and bound by 2 x metal tie wires. The humidity was created by a smaller container with water & salt that kept the RH between 70-80%RH and was left for 6 weeks. Measurements were taken at the times as per the spreadsheet so the box was opened at these times. Variations in the RH was caused by opening the box to take the measurements. If the RH was at the low end I would add more warm water and salt (this causes the RH to change quickly however). As an afterthought, I also added at the 4week mark before I went on Holidays, 4 x 10g(ish) Silica Gel packets so I had fully saturated desiccant to also add to the could drying phase.

Drying: After the 6 weeks I took the final "wet" measurements and placed one of each sample with 4 x dry Silica Gel packets into

- Food Dehydrator: Sunbeam DT6000 https://www.sunbeam.com.au/Food-Lab-Electronic-Dehydrator-1.aspx : Contained 1 x saturated PLA, PETG, ePA-CF, Silica Gel Packet & 4 x dry silica Gel Packets. At the time intervals for measurement, I would open the door weight each of the samples, the replace the door. Total time the door would be open would be a few minutes. The Deyhdrator and Vac Chamber was next to each other in my "shed" so had a more varied environmental RH and Temp than the Dry Cab and Freeser bag that were in my house.

- Vac Chamber: Generic 2Stage Vacuum Pump (strong enough to boil water): Contained 1 x saturated PLA, PETG, ePA-CF, Silica Gel Packet & 4 x dry silica Gel Packets. At the time intervals for measurement, I would release the vacuum, weight each of the samples. Total time not under vacuum would also be a few minutes. I'd then run the pump for a few minutes and turn it back off when at max vacuum. To me this is could be the most variable piece of equipment between us. It is also important to note that water stops boiling when the vacuum is OFF but my cheap pump would NOT survive days of running flat out. It was only run for a few minutes each measurement cycle and hence the influx of new air and pumping it back out was based on when the measurement tool place. I know that some people have a better pump that they leave running. Also of note was that the dry Silica Gell was absorbing moisture during this time.

- Dry Cabinet: eDry Ultra Low Humidity 250L Dry Cabinet Model SL-206CA : https://www.photoequipmentstore.com.au/edry-ultra-low-humidity-250l-dry-cabinet-sl-206ca-100-made-in-taiwan/ These puppies are expensive! Contained 1 x saturated PLA, PETG, ePA-CF, Silica Gel Packet (note: this cabinet also held at the time many spools of filament as it is my storage container). At the time intervals for measurement, I would release open the door, put the sample in the bag and go to the shed where I had setup the Dehydrator, Vacuum, and scale to weight each of the samples. Total time not in the Dry Cabinet could be 10 minutes. This and the fact that their is a recovery time for the dry chamber is the reason I did not take hourly measurements. The cabinet is located in my House (lower RH and more stable temp than the Vac and Dehydrator).

- Freezer Bag: Ziplock 1g Freezer Bag. Contained 1 x saturated PLA, PETG, ePA-CF, Silica Gel Packet & 4 x dry silica Gel Packets + temp/humidity sensor. At the time intervals for measurement, I would open the bag, take the measurements, put the samples back in the bag and squeeze out most of the air. Total time the exposed to the air would be a few minutes. The RH on cheap temp/humidity monitor was a max of 25% but normally just read "LL" so I have no idea what the RH was in the back. Sometimes it would read up to 25%. I kept it in the same room as my Dry Cabinet.

RE: Drying Times and Temps in Dehydrator

Summary of my Recommendations (FWIW) - balancing the costs and effectiveness of each of the methods, I'd generically recommend that most people would be fine with:

1) Storage: Plastic Tubs / Bags with Desiccant to keep filament "dry-ish" so that when:

2) Printing: Print from a modified Food Dehydrator which will both prevent the filament become moist when printing and will also further "dry" it out during the print. Just set the Temp of the Dehydrator as follows (recommended by printdry).

- Wet Spools: If you filament spool is already "wet" then it would be worth drying using the above table... but the times listed seem to be very, very optimistic to me. None of the samples I tested (and they were only 50g) where fully dry in these time frames, and I would expect 1kg spools to take much longer. So, the longer you can dry them before putting them into your storage container the better but even a few hours before printing or storage will make a significant difference as the rate of drying is quickest at the beginning.

- ePA-CF: The above advice seems solid for the likes of PLA, PETG, as they only absorb a relatively small amount of moisture and hence easy to store and dry out. Unfortunately, filaments like ePA-CF can absorb 5% of their weight so need a different approach. If you want to print with these you will need to be much more intensive as the fully saturated sample took days to dry. Storage may also need better than a "Freezer Bag" to keep it dry (but more tests are needed).

What about?:

- Vacuum Pumps / Chambers: Well they work..... but not as well as the much cheaper food dehydrator method for quickly drying wet filament. You also can not print from the Vac Chamber like you can with the Dehydrator. I'd not recommend these for general drying unless you already have one and don't want to buy a dehydrator. If you have neither, buy the Food Dehydrator. That said, they may be a good storage option for keeping spools as stuff like ePA-CF as you could put in 4 or 5 rolls, some desiccant, and pull a vacuum (yet to be tested).

- 0% RH Dry Cabinets: These work great for storage for all types of filament.... but are very, very expensive and for filaments like PETG and PLA are overkill. That said, I'm not giving mine up now I have them!

Thanks

Nathan

RE: Drying Times and Temps in Dehydrator

Nathan, and there lies the conundrum. I'm just throwing ideas out at this point, reasons we might have differences in results. You've done a lot of work and I do not want to diminish that effort in any way.

The upside is we agree the dehydrator is the quickest method to dry filament that has been exposed to moisture; and, for us home users freezer or vacuum drying is not really a satisfactory method.

Now for ideas. I suspect the addition of the silica packs mid stream in your saturation procedure nullifies any delta/time data collected, and probably skews saturation levels you achieved. Putting a drying agent into a humidity reference chamber, well, just sounds bad at the get-go since it will quickly suck moisture from everything in the chamber to reach equilibrium - drying the plastic samples in the process.

Also - I suspect combining different samples within a single vacuum chamber might skew results - especially if the pump wasn't running continuously. Though the physics of how water acts under high vacuum is a mystery to me - I now think keeping a moderate vacuum may be how the commercial dryers manage to remove more moisture quicker than simple heated air methods (high altitude dry rather than outer space vacuum).

Other thoughts? I'm jealous you have a dry chamber large enough to hold all your filament. I have a Peltier dehumidifier I should convert into such a chamber... but I get lazy any time I think of doing it and the notion of a refer sized cabinet in my kitchen just holding filament, well, seems over the top for me 😱 .

My PLA did NOT absorb moisture as fast as yours - mine took weeks to gain weight - in 100% RH no less. And despite the slower rise in saturation, my PLA gained more weight than yours did: by 50% (I reached around 0.75% by weight compared to your max of around 0.5%). Your adding gel packs during saturation may be related.

My vacuum pump (2-stage 5 CFM) drew out less of the moisture in the same time as a dehydrator: a mere 65% compare to 95% over 8 hours. And a vacuum had no effect on nearly dry filament (5% at the start and 5% after 8 hours at ~29.90 mmHg). More instructive, the dehydrator had removed 80% in only 4 hours. I suspect any differences here are due to my single sample tests compared to your multiple sample tests.

My tests agree favorably with most other recommendations for drying PLA: 4 hours is a good starting point, though 6 to 8 hours is needed to dry filament to under 5%. My dehydrator was operated inside my gas heated home, nominal winter RH around 15-20%@23c, so air inside the dehydrator was around 5% at 50c. Being outdoors, where ambient RH reaches 75% or more, the air inside your dehydrator may not have reached 15%@50c, substantially reducing the drying capability, slowing the drying process.

Overall - data is data, and adjusting for different test conditions is part of the process. Add the variables we have to deal with... good science is hard. Just ask Pons and Fleischmann - where a few calories of heat being miscounted disturbed the entire scientific community and metals futures market for a year.

RE: Drying Times and Temps in Dehydrator

I suspect the addition of the silica packs mid stream in your saturation procedure nullifies any delta/time data collected, and probably skews saturation levels you achieved. Putting a drying agent into a humidity reference chamber, well, just sounds bad at the get-go since it will quickly suck moisture from everything in the chamber to reach equilibrium - drying the plastic samples in the process.

I'm OK with it as I added the Silica Packs on the 2nd Jan after my last measurement before going on holidays. So the 2 week saturation data is completely unaffected. I then took two days of readings after I got back at the end of Jan to make sure the samples were not still gaining weight.

I suspect combining different samples within a single vacuum chamber might skew results

I agree, that combining the different samples in all the environments (Dryer, Vac, Bag, Cab) mean that moisture could migrate between the samples themselves till they are all completely dry. You can actually see the dry Silica Gel pack go UP in weight in the Dryer, Vac, and Bag as the filament dries (the sample in the Dryer then starts to go back down). The moisture has to go somewhere in closed environments like the Vac and Bag.

Though the physics of how water acts under high vacuum is a mystery to me

All are a mystery to me. I suspect all methods simply Lower the RH of the Atmosphere they are in. Higher the heat --> the lower the RH, higher the Vacuum --> lower the RH, more desiccant --> lower RH. Moisture in the filament just migrates out in the lower RH Environment till at some point they all reach equilibrium.

My PLA did NOT absorb moisture as fast as yours - mine took weeks to gain weight - in 100% RH no less

If I had to guess, I'd say the chemistry is different. My sample was Black eSun PLA+ (sorry have been calling it ePLA). It's some modified PLA that according to eSun has "superior" properties over "original" PLA.

My vacuum pump (2-stage 5 CFM) drew out less of the moisture in the same time as a dehydrator: a mere 65% compare to 95% over 8 hours.

Mine is 2-stage 9CFM model, so it probably pulls a slightly harder vacuum. It's really hard to accurately tell on how strong it is, as the pressure analogue dial is kind of useless towards max vac as even tiny differences makes a very big difference in lowering the boiling point of water. The only thing I can confirm is mine boils water. Our test method is also different. Mine gets very hot if I leave it run for an hour and as this went over days I did not want burn my house down. So I just run it for a couple of minuets after each measurements. I also had it loaded with all samples and the silica gel so moisture would have been migrating between these.

RH around 15-20%@23c, so air inside the dehydrator was around 5% at 50c

Luxury! It's summer here and as the tests ran over days, there was a big swings in temp and humidity (in both rooms). The environment on the first day for the Dehydrator and Vac was 30-38c / 45-66%RH and for the Cab and Bag it was 24-30c / 45-55%RH. This was one reason I had to push the Dehydrator Temp from 50c to 70c as it was just taking to long and I was going to run out of time. Once it hit 70c (too hot for PLA and probably PETG) but the extra lowering of the RH really kicked it into gear.

Overall - data is data, and adjusting for different test conditions is part of the process

Yup and that is why I've now moved on (well I still have my 2 x ePA-CF samples in the Bag and Dry Cab going) to taking a step back from the details to a "Summary of my Recommendations" which I think is in line with what you found as well?? At the end of they most will want to know what to do to have "dry-enough" filament.

RE: Drying Times and Temps in Dehydrator

Good info guys. I think the ZipLoc freezer bag(s) with a packet of desiccant are good for storage, and "when in doubt, dry it out" for drying. I think a basic dehydrator is a good investment for most users.

I plan to make a note on ambient temp and RH before long prints to see if I can nail down what causes some PLA to go bonkers for a bit, then recover.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Drying Times and Temps in Dehydrator

Sounds good. Bet you a beer you find that the "PLA goes bonkers and recovers" follows an increase then decrease in RH%. It will be interesting to see what you find. If it continues to be an issue then setup a dehydrator as a print box.

RE: Drying Times and Temps in Dehydrator

Oh it definitely correlated with swings in RH, but was unusual is that it went from "a little stringing" one day to "none at all" when we had a dry Arctic blast that dropped RH to 10-15% in my office. Then this happened (read dates below pics). Have not had a recurrence with swings in RH since. So I'm wondering if it was the drop so low then rapid swing up in RH that did it (short interval with lower starting level of moisture), something like condensation on the filament (which I'd expect to cook-off before the nozzle) or just something about that period (cooler room, Paramount formulation, full moon). It was the oddest episode I've had with PLA.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Drying Times and Temps in Dehydrator

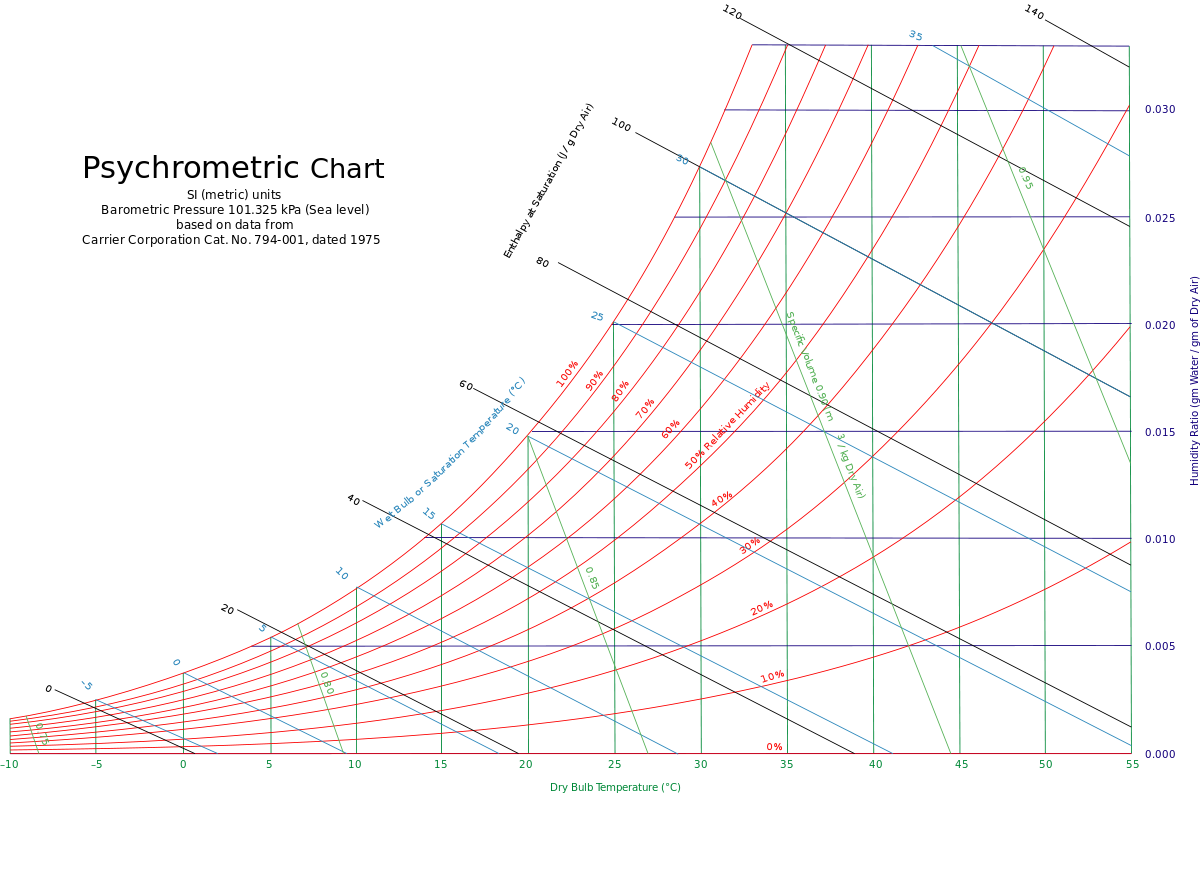

Nathan, it's my opinion your dehydrator was doing very little to dry your filament: using that chart as a reference, with an ambient average of 55%RH @ 35c, your dryer was only getting to ~26% @ 50c; compared to my dehydrator hitting ~7% @ 50c.

I'll probably do few more experiments, but only to map out variables in filament brands I use. Most important, I'll dry anything like Nylon or ABS before printing; but only indoors 😨 .

RE: Drying Times and Temps in Dehydrator

Nice Model. I can see what you mean by the stringing 😮 ...but I'm not sure what pic corresponds with what RH however.

All I know is that my PLA+ absorbs and sheds moisture quickly (in line with the change of RH of the environment) and that the rate of change slows over time till it reaches equilibrium. I don't know if this would make a difference in what you are seeing, but it would also be fair to say that as filament absorbs moisture it starts from the skin of the filament and works inwards. So the outside of the filament will always be wetter than the core will be till fully saturated at a particular RH. When the RH drops the skin of the filament will start to dry out first and water will migrate from the core till fully dry at that particular RH. The amount of moisure the filament holds is relative to the RH of the environment it is in. My PLA will hold 0.55% more moisture at 80% RH than 0% RH.

RE: Drying Times and Temps in Dehydrator

Nathan, it's my opinion your dehydrator was doing very little to dry your filament: using that chart as a reference, with an ambient average of 55%RH @ 35c, your dryer was only getting to ~26% @ 50c; compared to my dehydrator hitting ~7% @ 50c.

I'll probably do few more experiments, but only to map out variables in filament brands I use. Most important, I'll dry anything like Nylon or ABS before printing; but only indoors 😨 .

Yup - it would explain why it stalled 0.11% when at 50c and when I increase it 70c it dried all they way. It's the differential that is important. Even the printdry site says "It is highly recommended to use a dehumidifier or several dehumidifiers to keep the ambient humidity low in your printing room."

RE: Drying Times and Temps in Dehydrator

Read an interesting article stating that the absorbtion will also vary depending on the spool used. A spool with solid sides will take longer to saturate than one with open sides and also longer to dry out. The outer layers will be the most saturated. In other words, you might have to do testing with full spools to get anything meaningful! Not something I'm up for anytime soon.

The pic sequence was after the days of unusually low RH, so about 25-30%. Printing more-or-less normally in the December pic, then insane stringing. Dried the spool before the last pic.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Drying Times and Temps in Dehydrator

I was also thinking of the spools as well, but from the fact that they too are made from some type of plastic and will also have their own levels of absorption that would influence the filament as well....and they would also be a big part of the weight especially as you use up the filament. Sooo many variables. Anyway, still sticking with the simple: If you Keep it Dry and then Print it Dry = All good to go! ....and the rest all becomes kind of esoteric.

RE: Drying Times and Temps in Dehydrator

Quoting Guys opening line to this thread:

For those who lack a filament drying system, get one. Even spools from unopened, factory sealed bags can be moist enough to spoil print results.

I got a brand new reel of PETG yesterday (T-Glass) which was vacuum sealed with a sachet of desiccant gel inside and I opened it and did a print of a part I need, and it printed quite well, a few pops and some stringing, but nothing much.

Finished the print and had to go out for a few hours before doing another print of the same part, so popped the reel of filament in my dehydrator set at 65 Deg C.

Came back 5 hours later and put it on the printer, immediately, no pops during loading, and not even 1 string during printing.

So as Guy stated, brand new factory sealed filament is no guarantee of a dry filament. Buying a dehydrator is really a no brainier for good reliable printing, and whilst I would like to have a dehydrator like Guy bought (I nearly did but SWMBO has nicked it), a cheap dehydrator works just as well, but will only hold a couple of reels at a time, which for most people is good enough.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Drying Times and Temps in Dehydrator

Here's what I ended up with: it was quite a bit less when I ordered tho. It has a couple of quirks to the UI: display never turns off, and not much indication it's running other than noise and declining digits, where they are sort of static when idle. Only displays in F, only heats to 165F, holds temp within +/-5F most the time (I'd prefer +/-3F). It will hold several spools at once: three or four tall, and two diagonally front to back if they are partial spools and can overlap a half inch or so. For my kitchen: primary was appearance, this one is pretty.

https://www.amazon.com/COSORI-Dehydrator-Stainless-Temperature-Compliant/dp/B07PY5M579

RE: Drying Times and Temps in Dehydrator

^ They didn't have that model when I bought my dehydrator SWMBO nicked, but if they did, it would have been taken even quicker! 😊

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.