Drying Material in a Vacuum

So I started this thread because a lot of people seem to have issues drying material and keeping them dry. I'm not the expert but will share what I know and hope that everyone else will chime in and we can resolve all of the issues.

My background is injection molding and thermoforming. I dry 500,000 lbs of PC and ABS sheet every year for thermoforming and we do it in a gas oven with a lot of air movement. We have a 15'X20' oven with a 36,000 cfm fan circulating dry hot air. The temps range from 150F to 200F depending on the material type. The time can range from 4 hours up to 24 hours depending on the thickness of the sheet. After drying we rap the material back up in plastic. ABS will last a couple of weeks and PC will only last 1 at the most. What is interesting is that most of the time water absorption is only a .005" - .010". deep. We can form wet sheet and see the blisters only on the surface. When we cross-section the sheet you can clearly see the that the center of the sheet is still dry.

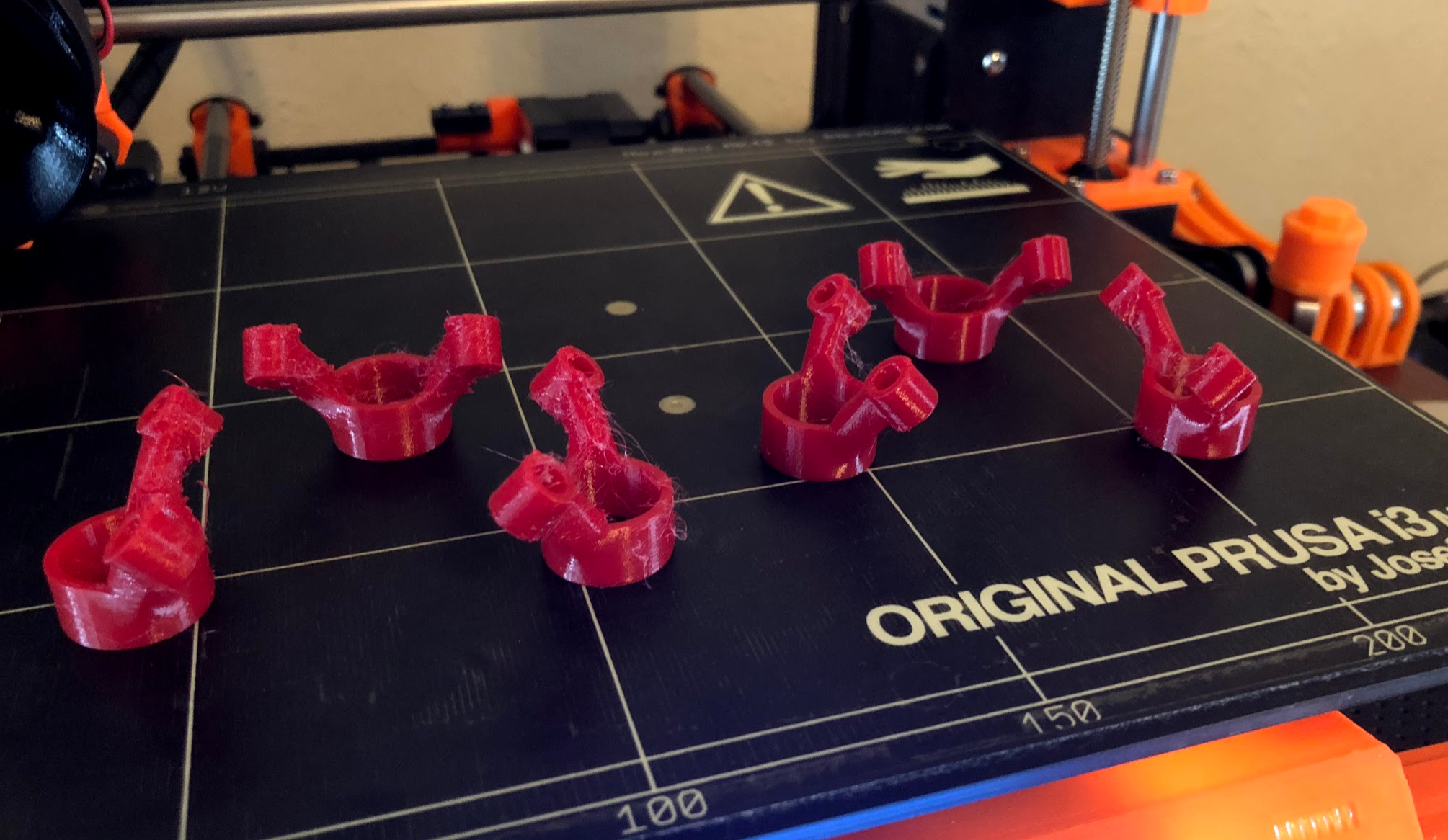

I have researched small batch pellet dryers and have come across drying the material in a vacuum. You can lower the boiling point of water and not have to heat the material up as much as just drying alone. I have started building a small 2 roll dryer. I have attached pictures.

The BOL:

10 gallon air tank. Might have to reinforce if the vacuum pressure to too great. We will see. $40.00 from Northern Tool

1 charcoal igniter. $22.00 Home Depot

1 temp controller with thermostat and 110v outlet. Amazon $35.00

Small grate to fit at the half way point of the tank to keep the starter away from the spool of the material and reinforce the walls.

1 HVAC Vacuum pump and hoses to connect to tank. $60.00 Amazon. Shop vac will not work!

1 cap with seal to create the vacuum chamber.

Based on the information I have gathered, I should be able to heat the material to 130F for 20 to 30 minutes and then turn the vacuum on for another 20 to 30 minutes while keeping the heat on. Chamber should be able to hold 26HG vacuum. This should keep the spool holder from melting and dry the material very well. The only issue I can see is that we will need to heat the material thoroughly. The soak time may vary have to be dialed in.

I have attached some pictures of the start of the project and hope to complete it in the next few weeks.

I am open to all suggestions if anyone has anything to add.

Re: Drying Material in a Vacuum

This is working well for me:

https://www.amazon.com/gp/product/B008H2OEKK/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

I cut out the plastic insides and dry up to 2 rolls of plastic at a time. I don't print ABS nor PC (yet), but I've had great success with drying out Nylon, Ninjatek Cheetah and PETG from a few hours before printing. I live in Florida, and the humidity is just too high to keep up with. I've tried containers with a seal and some desicant packs (not the lot of beads that others have recommended, I may still try those). Me and my wife weren't keen on the idea of using our oven to heat up plastic, even at low temp to dry it out. This is a nice compromise because I can store it anywhere.

I didn't come up with this tip, I got it from Safety Glasses Required (he used it even for PLA).

Example on Flexible filament

Re: Drying Material in a Vacuum

Very interesting. I have access to some powerful vacuum chambers. I'll soak some petg in water and see what kind of results I get.

Re: Drying Material in a Vacuum

Regarding the OP, are you saying that off the shelf filament dryers (e.g. https://www.matterhackers.com/store/l/printdry-filament-drying-system/sk/MNXQRWQC?rcode=GAT9HR&gclid=Cj0KCQjw3InYBRCLARIsAG6bfMSCe6ACGSSE1IsvWt1PvnY26kcI54cyIfphEt3Qli2xA64XyuwtFcQaAi4ZEALw_wcB ) are ineffective? I'm just wondering why go to the extra effort of creating a vacuum if they do actually work. I haven't tried one, so I honestly don't know one way or the other, but I am close to pulling the trigger on buying one.

Re: Drying Material in a Vacuum

Regarding the OP, are you saying that off the shelf filament dryers (e.g. https://www.matterhackers.com/store/l/printdry-filament-drying-system/sk/MNXQRWQC?rcode=GAT9HR&gclid=Cj0KCQjw3InYBRCLARIsAG6bfMSCe6ACGSSE1IsvWt1PvnY26kcI54cyIfphEt3Qli2xA64XyuwtFcQaAi4ZEALw_wcB ) are ineffective? I'm just wondering why go to the extra effort of creating a vacuum if they do actually work. I haven't tried one, so I honestly don't know one way or the other, but I am close to pulling the trigger on buying one.

That one is a waste of money not because it doesn’t work, but because it is nothing more than a rebranded food dehydrator. The one I linked above works great for me. I just had to modify it to fit the spoils in there. I currently have it topped out at 2 spoil height, but I have more sections where I could probably fit 3-4 spools in there. If you want to save some money, I’ll try to find the exact food dehydrator PrintDry is. I know I saw it somewhere exactly the same for a lot less (minus holes for the filament to feed out of).

Re: Drying Material in a Vacuum

If you want to save some money, I’ll try to find the exact food dehydrator PrintDry is.

Yes, I'm interested.

Re: Drying Material in a Vacuum

I´ve read somewhere (maybe on reddit.com/r/3Dprinting...) the PrintDry is just a rebranded Westinghouse WFD101W with some injection moulded spool trays.

Look´s the same to me: https://www.amazon.com/Westinghouse-Dehydrator-Preservation-Dehydration-WFD101W/dp/B0188X0UT6

Re: Drying Material in a Vacuum

I wonder if it even works at all? I mean, to the OP's point, the temperatures are less than the boiling point of water. The vacuum he's proposing would be to reduce water boiling point to where it would boil off at a lower temperature. Of course, then what? Do you need to keep the whole chamber heated so that it doesn't reabsorb? Or does desiccant inside the chamber absorb it? Or,....? Perhaps in a vacuum and at temperature, the desiccant itself would release any water vapor it had already managed to scrounge.

Re: Drying Material in a Vacuum

The way I dry sheet at work is by passing large amounts of hot dry air around it for hours. To dry .25" PC sheet we would heat up the oven to 190F and let it run for 8-10 hours. Heating it up allows the material to open up and the hot dry air evaporates the moisture in the sheet. We have to use gas heat or the drying time could double if we use electric heat. I am using an electric heater so adding vacuum will pull all of the moisture out of the chamber. It also allows the water to to boil at much lower temps. There would not be a need to use any desiccants because there will be no air or water in the chamber when you add vacuum. The only variable is how long does it take each material to "open up". PC and Nylon are very hygroscopic. ABS would be a little less. Not sure about PLA. A good test would be to weigh a small printed object soak it in water for a day or so and weigh it again.

https://www.ptonline.com/kc/Plastics-Drying/Dryer-Types/Vacuum-Dryers

The article above is where I got the idea.

Re: Drying Material in a Vacuum

Regarding the OP, are you saying that off the shelf filament dryers (e.g. https://www.matterhackers.com/store/l/printdry-filament-drying-system/sk/MNXQRWQC?rcode=GAT9HR&gclid=Cj0KCQjw3InYBRCLARIsAG6bfMSCe6ACGSSE1IsvWt1PvnY26kcI54cyIfphEt3Qli2xA64XyuwtFcQaAi4ZEALw_wcB ) are ineffective? I'm just wondering why go to the extra effort of creating a vacuum if they do actually work. I haven't tried one, so I honestly don't know one way or the other, but I am close to pulling the trigger on buying one.

Wow, $129 !

That's a rebadged $30 food deyhydrator !

Like this > https://tinyurl.com/yaz3asyt

Re: Drying Material in a Vacuum

I´ve read somewhere (maybe on reddit.com/r/3Dprinting...) the PrintDry is just a rebranded Westinghouse WFD101W with some injection moulded spool trays.

Look´s the same to me: https://www.amazon.com/Westinghouse-Dehydrator-Preservation-Dehydration-WFD101W/dp/B0188X0UT6

I can't believe the markup. That is the exact same model. There is no question about it.

Re: Drying Material in a Vacuum

I´ve read somewhere (maybe on reddit.com/r/3Dprinting...) the PrintDry is just a rebranded Westinghouse WFD101W with some injection moulded spool trays.

Look´s the same to me: https://www.amazon.com/Westinghouse-Dehydrator-Preservation-Dehydration-WFD101W/dp/B0188X0UT6

Thanks for the tip! I just ordered one. For the price, seems like a no-brainer: same ballpark as the cost of a roll of filament.

Re: Drying Material in a Vacuum

I´ve read somewhere (maybe on reddit.com/r/3Dprinting...) the PrintDry is just a rebranded Westinghouse WFD101W with some injection moulded spool trays.

Look´s the same to me: https://www.amazon.com/Westinghouse-Dehydrator-Preservation-Dehydration-WFD101W/dp/B0188X0UT6

Thanks for the tip! I just ordered one. For the price, seems like a no-brainer: $37 with free delivery is same ballpark as the cost of a roll of PETG filament.

Sorry if we derailed the OP. Let's get back to the OP's topic, which is no less interesting. Is his way is better? That's the key question.

One of his ideas I like a lot: weighing the sample before and after. I'll try weighing some leftover PETG filament before I food dehydrate it and then again afterward, and I'll report back.

Re: Drying Material in a Vacuum

I use a vacuum oven

Re: Drying Material in a Vacuum

I'd love to know how the vacuum chamber came out. I was discussing building a heated vacuum chamber vs a modified food dehydrator for my own filament drying needs with a buddy of mine. He tested both and determined, based on print quality, that the food dehydrator seemed to work better and took less effort to achieve the desired results. Once the filament is done drying - he uses a cheap food saver vacuum machine and some silica gel packets to seal the filament off from the rest of the world. I've elected to do the same Westinghouse food dehydrator as this posting has and actually JUST finished modifying it for this purpose.

Please tell us how the vacuum chamber is working out; it's an interesting project.

Re: Drying Material in a Vacuum

Very interesting concept.

--------------------

Chuck H

3D Printer Review Blog

Re: Drying Material in a Vacuum

I use a food dehydrator that has enough room for about 8 spools at a time. After drying I put those I'm not using into a vacuum bag used for storing clothes and the like. I have noticed a slight amount of vacuum welding when I do this. Not much but enough to make the layers a little "sticky" when I use them.

Neal

Re: Drying Material in a Vacuum

Are you able to see marks on the filament where you've experienced the "vacuum welding"? I wonder what going on there. Which kind of filament have you experienced this on? Has it ever affected your printers ability to function?

Re: Drying Material in a Vacuum

Are you able to see marks on the filament where you've experienced the "vacuum welding"? I wonder what going on there. Which kind of filament have you experienced this on? Has it ever affected your printers ability to function?

Yes the marks are visible on darker filaments. It is a lighter colored streak where the two "welded". I have seen it on PLA, ABS, and PETG made/ sold by Prusa, TinyMachines, Fillamentum, Rigid Ink, MatterHackers, and MakerGeeks.

And, lastly, no I have not seen any problems with my machines. Creality CR-2020, Creality Ender2, Creality CR-10S, MK2S, or MK3.

Neal

Re: Drying Material in a Vacuum

That's an interesting result. I thought I was getting the "vacuum welding" you are referring to as well, but it turned out that I had the temp set too high in the dehydrator and was getting into the G.T. temp zone of my materials, which ultimately ruined a role of PETG. I haven't directly experienced the welding you describe since adjusting my temperature.