Crash detection not working with powder-coat sheet

I recently finished building my MK3S and I have the powder-coated steel sheet. I spent hours of frustration with non-adhesion no matter how I calibrated the first layer, until I saw another thread here that advised washing the sheet thoroughly in dish soap first, and that fixed it.

However, the PLA adhesion is still poor:

- I always need a brim for everything, to give the part some extra surface area on the bed.

- With a brim, parts will print just fine, but even then I never need to remove the sheet from the heat bed. Just tapping or pulling gently on the part is enough to free it. It should stick better.

- Worse yet, crash detection does not work. If a problem occurs that results in plastic buildup for the nozzle to crash into, the part breaks free first.

This happened to me just last night. I was trying to print something at 0.05mm layer height, and possibly a glob of filament formed on some support structure, and a few layers later it built up into a mound of plastic that the nozzle kept crashing into, noisily. A couple more minutes of this resulted in the part breaking loose from the bed.

Now, this crashing was primarily in the Y direction, so I don't know if that matters. But the crashing was never detected, even though it was obviously happening.

To improve adhesion, I wonder if I could buff the sheet with a scouring pad, or 3000-grit sandpaper? I have two sides to the sheet, so I can experiment with one.

RE: Crash detection not working with powder-coat sheet

wash with plain dish detergent ( dawn/fairy) and lots of water , using only clean paper towels to scrub

dry with more clean paper towels with out touching the surface

dry completely by putting the sheet back on the heated bed to drive off any moisture

RE: Crash detection not working with powder-coat sheet

@david-a66 - yes, I have done all that. Twice. I have washed the sheet with Dawn, rinsed it thoroughly until the water runs off without leaving a film, and touched it only with paper towels. The rest of my cleaning is with 99% isopropyl alcohol. PLA simply does not stick well to this. That is why I asked about a scouring pad or fine sandpaper.

This printer is only a few weeks old, so I have the new sheets. The older powder-coat sheets had a bit more roughness, based on what I've read in other threads.

RE: Crash detection not working with powder-coat sheet

you may need to make your live more negative -

RE: Crash detection not working with powder-coat sheet

Encountering a part that has popped loose from the bed is not crashing.

Crashing is hitting something firmly attached to the bed. It is detected by an increase in motor resistance.

RE: Crash detection not working with powder-coat sheet

you may need to make your live more negative -

No, when I do that, the plastic tears away from the bed. The test patch that I get is very typical of the example photo of the nozzle being too close. I have done the first-layer calibration countless times now.

RE: Crash detection not working with powder-coat sheet

Encountering a part that has popped loose from the bed is not crashing.

Crashing is hitting something firmly attached to the bed. It is detected by an increase in motor resistance.

This is more than merely a part that popped loose. I would call this crashing. When the nozzle moves in the y direction and encounters an obstacle, the extruder pivots a bit on its top rail and goes over it. After hitting the obstacle enough times, the part is eventually knocked loose from the bed. The impact is very obvious and very loud, but likely not causing much resistance because the extruder is rising up a bit to go over the obstacle.

IF my part was more firmly adhered to the bed (that's the problem with PLA and powder coating), then the part wouldn't pop off, and the crash detection should kick in. The fact that it doesn't kick in, even after multiple impacts that eventually knocks off the part, suggests that the crash detection isn't calibrated properly for a powder-coated sheet.

At least, that seems to be the case for y-direction crashing. There are different dynamic forces going on versus x-direction crashing.

RE: Crash detection not working with powder-coat sheet

Best test for crash detection is self test. Axis calibration uses the same increase in motor resistance.

Does self test still pass?

RE: Crash detection not working with powder-coat sheet

This happened to me just last night. I was trying to print something at 0.05mm layer height, and possibly a glob of filament formed on some support structure, and a few layers later it built up into a mound of plastic that the nozzle kept crashing into, noisily. A couple more minutes of this resulted in the part breaking loose from the bed.

......

To improve adhesion, I wonder if I could buff the sheet with a scouring pad, or 3000-grit sandpaper? I have two sides to the sheet, so I can experiment with one.

Have you tried printing an object at the 0.20 or 0.30 layer height before scratching up a new sheet? The 0.05 print setting is much more finicky than other layer heights. The descriptions are deceptive in that people thing that ultra detail is better than 0.15 Quality or 0.20 Quality print settings. I would try those first and see if it still happens before making other changes

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

RE: Crash detection not working with powder-coat sheet

Have you tried printing an object at the 0.20 or 0.30 layer height before scratching up a new sheet? The 0.05 print setting is much more finicky than other layer heights. The descriptions are deceptive in that people thing that ultra detail is better than 0.15 Quality or 0.20 Quality print settings. I would try those first and see if it still happens before making other changes

I can try that as an experiment. There were two reasons I didn't:

- I had already printed another smaller part successfully with that mid-print layer adjustment feature in PrusaSlicer to go down to 0.05mm for part of the print. It worked very well, so I figured a whole part done that way would work too.

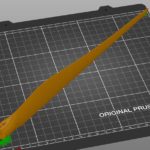

- The object I'm printing now is a rocket fin symmetrical airfoil, printed on its side to get sharp knife edges. Larger layer size would result in rather severe stepping over the curvature of the airfoil. Given that I need sharp edges and smooth shallow curves, I am kind of forced into the smallest layer height. I've got another post here about that.

RE: Crash detection not working with powder-coat sheet

Folks - in the OP's other post his print shows an extremely bad layer 1, especially for the textured sheet. Print temp is way high (the plastic is oozing after it is laid down, almost like he's print PLA at 250c, and his mechanics are questionable: loose belts, etc. No wonder he's having issues.

But crash detection has nothing to do with a fur-ball on the nozzle. I suspect crash detection is working as expected, and not sounding an alarm because the OP is having no crashes. Just bad Live-Z calibration and lifting parts.

RE: Crash detection not working with powder-coat sheet

@tim-m30 - I'm printing with the standard PLA settings, 215 C. My belts are tight, right in the middle of the range recommended to be shown on the display. I could tighten them a bit more at the risk of stretching them. If I try to make more negative Z in first layer calibration (I have lost count of the number of times I've done this), I get the little test pad showing torn areas.

I've had several excellent prints of other parts already (the frog turned out beautifully). Is it possible that my temperature sensor is off? I doubt it's 250 C.

RE: Crash detection not working with powder-coat sheet

The LCD display belt numbers are useless indicators when it comes to belt tension. My belts are plenty tight at 295. Prusa says I should be at 240 ?? lol. I'd be bending metal if I pulled things that tight, and probably way over to 100lbf/inch Gates recommends as maximum tension. And, if I relax my belts from where they are, they can almost slip over the drive gears and my belt numbers on the LCD don't change after a self test.

Are you printing in an enclosure? Is the extruder cooling fan running? Is the part cooling fan running?

RE: Crash detection not working with powder-coat sheet

Try printing this test circle - make sure you ONLY print layer 1. It should peel off the bed and be a solid sheet of plastic, not a stringy mat.

RE: Crash detection not working with powder-coat sheet

ps: as an aside, a fin actually works better if the leading edge is correct rather than sharp. Look at any NACA airfoil and you'll see the leading edge is always radiused rather than razor sharp. It is a fallacy a sharp edge cuts through air better. Fluids don't work that way.

RE: Crash detection not working with powder-coat sheet

ps: as an aside, a fin actually works better if the leading edge is correct rather than sharp. Look at any NACA airfoil and you'll see the leading edge is always radiused rather than razor sharp. It is a fallacy a sharp edge cuts through air better. Fluids don't work that way.

I'm referring to the trailing edge being sharp. A non-sharp trailing edge contributes to drag way more than a deformity on the leading edge. The leading edge isn't a problem. I'm using the NACA formula for the airfoil cross section (a shape generator I built in Tinkercad).

Thanks for the cal circle. I'll try it tonight after my 10-year old boy goes to bed -- he and I built the printer and he'll get distracted from his homework if I start experimenting on "his" printer now. 😀

BTW are you also using a powder-coat sheet? Most folks here seem to be using PEI.

RE: Crash detection not working with powder-coat sheet

Try printing this test circle - make sure you ONLY print layer 1. It should peel off the bed and be a solid sheet of plastic, not a stringy mat.

You were right. Even though the printer's first-layer calibration was giving me a nice solid patch, your test circle came out stringy. I was able to reduce the z position a whole 0.05 mm, and now the cal circle prints out solid.

Thanks so much for that. For good measure, I also tightened my belts a bit, even though they already seemed tight (I was unable to make them slip or buckle when applying a lot of force). They sound sort of like a bass guitar string when I pluck them.

RE: Crash detection not working with powder-coat sheet

I only use the smooth PEI shown in the photo. Same sheet I've been using for well over a year now.

I only use soap and water to clean it, with a rare acetone scrub to refresh it or remove old PLA residue (less than once a month). Reading others here, they are having issues with the PC sheet and PLA. Washing with soap and water gets PLA to stick for a while, but soon the adhesion problem comes back. Alcohol is also worthless for cleaning well enough to get PLA to stick. Seems the sheet is best for PETG.

You might try reducing print temps for the second layer and up (215 for layer 1 helps PLA stick). 210 for the other layers looks too hot to my eye, I'd drop down to 200 for other layers and see how the plastic is looking once printed.

Belt tone should be about 220 Hz (from folk who have used tuning meters to test) - so yours sound close enough.

Is there any way to orient the fin so it prints vertical? This was a very hard print, but I got it to work:

Pretty sure I ended up with a brim, and had some finish work on the leading edge. But it's been a while.

RE: Crash detection not working with powder-coat sheet

[...]

BTW are you also using a powder-coat sheet? Most folks here seem to be using PEI.

Sorry for intruding, but you tickled a pet-peeve of mine. Both sheets sold by Prusa are PEI surface sheets. The way the PEI is attached is the difference. The textured sheet is power coated, and the smooth sheet is an adhesive sticker.

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: Crash detection not working with powder-coat sheet

Same basic material Polyelthyl-something, but I'm guessing the formulations are radically different. It's like calling all nylons nylon, or all steels steel, even stainless isn't unique:

Outokumpu's stainless steels can be divided into four main types: ferritic, martensitic and precipitation hardening, duplex, and austenitic – the best steel for you depends on the application. The standard ferritic grades are alloyed with chromium (11.2–19%), but with no, or a very small, addition of nickel.

Then there is this type of PEI (first hit on Google), proof not all PEI is the same, lol:

As a result, PEI is guaranteed its current four seats. There are three levels of municipal government in the province: city, town and community.Apr 8, 2009Prince Edward Island | The Canadian Encyclopedia

So smooth vs textured is my preference. What throws me is when someone has something else and never state the fact they are using aftermarket and expect similar performance, sheets and whatever.

...