Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Hello to everyone,

Following extensive reading about Prusa and it’s mentality as a company as well as various threads in this community (friendly and helpful) I am leaning significantly towards considering either a MK3 or a MK2S printer as my first 3d printer. I would very much appreciate your input/feedback with respect to the suitability of either printers for my intended use. Apologies in advance for the long post, (but this seems to be the best place to ask these questions) and many thanks also in advance for your time and replies, they are much appreciated.

I need the printer for making scale model prototypes (non-organic forms), at a professional/prosumer level. I want to be using HIPS (styrene) filaments mostly (almost exclusively I would say). Subsequently I need the following:

1. Print quality (50-100 microns)

2. Repeatability-consistency,

3, High dimensional accuracy of the prints

4. Reliability of the machine

5. Linux-friendly (linux only here…)

6. Superb performance when using HIPS (see points 1,2,3)

Based on the above, am I correct in looking into getting a MK2s or a MK3? (During my market research I have also considered the CR10s, but I think it wont print HIPS as good as the Prusa based on the hotend/heatbed it has and in most cases I read that a Prusa will be better for my 1-5 needs)

Q1: Will a MK3 or MK2s excel at the above in stock form? (covering all the aforementioned needs)

Q2: Choosing between the MK2S and the MK3…. I like a lot some of the features of the MK3 (more silent, faster, removable spring-steel sheet on the heatbed), but I am concerned a bit about some of the prints and the discussions I have seen showing the “inconsistent extrusion” (maybe over-exaggerated i think). The latter in combination with the lower price makes me consider the MK2S as well as the MK3. I would very much appreciate your feedback in this dilemma as well.

Q3: I am considering kits only, since I appreciate the experience of building it plus I think it will give me precious knowledge with respect to troubleshooting (and 3d printing in general) down the road. Am I thinking this right here?

PS. I am aware that I ll be needing post processing on most of my prints in order to eliminate layers etc… this is why I want HIPS (experience in working with styrene). Furthermore this is why I need #3 on my needs’ list in order to have super-accurate structure-forms as bases for post processing (with sharp and well defined edges/geometry).

Thanks again, in advance and once more, apologies for the long read.

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

to be completely honest, this is a high end hobbyist-class machine. Its popular for good reason, and it is sub 1000$ for good reason. In a truly professional setting you want to look at something at least partially enclosed and NOT made from printed parts.

its a good kit and you can learn a lot, but be aware of the limitations (#1 being the 200lb gorilla putting together the kit)

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

While what Curtis indicates is all true and a fair opinion. I differ on their use solely as a hobbyist machine. Many folks are using these professionally in small to mid-size print farms with great results. An enclosure can be adopted very easily and economically, and instructions and printed models are provided by Prusa as well as dozens of others. Being that you expect to do some post-processing, I would ignore concerns of the inconsistent extrusion. It is mostly splitting hairs. I have two MK2S units, one with the original MMU and two MK3s. Both are fantastic and have thousands of hours between them. The MK2 frame is very workable and easily squared if you follow the engineering documents as well as the instructions. I have adjusted the frame perhaps once or twice in over a year and a half. It is however much simpler to assemble the MK3 due to the extrusions being used for the frame. The E3D v6 is the gold standard for extruders, and both units use it. The build plate system for the MK3 is absolutely fantastic and provides more functionality than is even initially apparent. Being removable and double-sided, you have a ready sheet available should something happen to one side of the unit even if you don't purchase any others. This is a value add in usability and redundancy of sorts. The MK3 is definitely quieter, has better and more sensors(not required) as well as better equipt to handle flexible filaments should you want to.

So long story short, both units would meet your requirements just fine. If budget is your number one concern than the MK2S is for you, otherwise, the actual value and additional ease of use in the MK3 make it a no-brainer. The cost difference is $143.72 which can easily be seen in just the Bondtech gears as well as the removable build surface. The rest is metaphoric gravy. The continuous enhancements to their software and firmware packages are pretty incredible as well. Prusa pretty much has taken over the Slic3r project and continues to impress considering it is not a direct revenue generating work.

In comparison with the CR10 I would say that the Prusa is going to stand by and support you much better than Creality, but they have a strong community as well. If you need that large a build volume it may not be a bad choice on a budget, but if you don't need it, you would be better served with a Prusa IMHO. In any event, welcome to the community and hopefully, you have a great experience, and results from whatever you choose.

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Curtis.c2 and devdoc many thanks for your helpful replies!

I can (and plan to), enclose the printer if needed and to be honest for dust and fumes i will most probably do it sooner than later with a either a lack-based-built or a custom-built wood/plexiglass enclosure (with a fan extractor and carbon filter most probably). Your detailed reply helped a lot but got me a few more questions (sorry 🙂 ).

Why should the printed parts being components of the printer concern me in a professional setting? Reliability? They don't last long?

I like the fact that the MK2S is cheaper and possibly does not get affected by the inconsistent extrusion as much as the MK3 (lack of bondtech gears?). However, the non removable build plate means that if something happens to it, i cannot replace it on the fly as i could with a magnetic one on the MK3 right? ( for example, a plus on the CR10S is that glass plates are removable/replaceable easily).

Also if i get it right, you can do without a spatula and adhesives with the removable flexible PEI plate on the MK3 (?).

Another plus for the MK3 in my view is the 24V vs 12V since i guess this affects the temperatures achievable by the heated-bed right?. Or the MK2S is as capable in printing HIPS as well as the MK3?

With respect to build volume and the CR-10S, i can use it but i do not need it as i can assemble the final object out of smaller 3d printed parts (i am a kit builder in general and prefer kits). What i need is reliability, support, and high quality/accuracy HIPS prints

From what i have seen so far, Prusa i3's look like a high-quality refined linux distribution in 3d-printer form, if i could use this metaphor. This metaphor, along with my needs in post #1 and the reliability/support factor led me here. This community forum along with some time spent in the last couple of days with slic3r PE further confirm my decision to lean towards Prusa as a choice.

Two (for now) important concluding questions,

Q1. Can the MK3 print as good as the MK2S, using HIPS (and PLA)? As i said, i am mostly concerned with non-organic forms (vehicles, structures, buildings etc...). If it can, and the "inconsistent extrusion" is a non-issue, then i am settled for a MK3. If not, then MK2S.

Q2. Is getting a kit a right decision? I want to learn about the printer and i am a kit builder in general (i prefer kits and learning the engineering mechanics behind the objects/machines in question). I suppose a kit comes with full warranty on the parts themselves right? (for example, faulty motors, bent structural part, bearings , pcb's etc...)

Many thanks again for your valuable time and replies, and glad to have become a member of this community!

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Good morning,

The MK3 and MK2 almost print identically with all materials (HIPS and PLA no problem). You would be hard pressed to see the differences unless looking for them at specifically angled lighting conditions, and it does not impact mechanical functionality or accuracy of the parts. Many of the folks in that discussion simply do not have their printers/slicers calibrated or have other issues not related to the topic of inconsistent extrusion. To be honest I wouldn't have even noticed until the hysteria hit. The MK3 excels at time savings in the way of the removable bed plate as well as quicker heat up times as you noted. This is the real benefit to the 24v as well as it is required for a proper TMC2130 implementation. Both however can achieve bed temps of 110C without issue.

I have never had a problem with printed parts, however accidents do happen and any plastic parts are more vulnerable to their metal counterparts typically. You can reprint any of the parts, and it is also recommended to have spares on hand should anything go wrong. This is actually better than having an equivalent system in which you can not reproduce the parts at the cost of pennies, nor can you do it yourself. You can purchase the removable bed and plate for the MK2 directly from Prusa for $120, but again this puts you almost at the price difference right out of the gate. the same goes for upgrading the MK2 to MK2.5...same price( a little higher actually) as MK3. The kits are easy to assemble, but the MK3 will save you several hours initially and takes that part of the calibration\adjustment out of the mix. If you are handy with an Allen wrench, a screwdriver, and a pair off needle nose plyers (add crescent wrench for MK2), and can read and follow very a very well documented and commented pictorial instruction manual, you are all set. You simply need to set aside the time, and do it.

The parts are all neatly separated into packaging for each individual step which makes it simple for even the most disorganized of builders. The kit also includes critical spares for the occasional drop into an AC vent or shag carpeting should it disappear. A nice 3D print spatula (rounded edges and deburred) is always nice to have but not really required with the flex sheet. It comes in handy for removing skirts and very small items which are not affected by the bending of the sheet but none the less it could be done with a plastic scraper or loyalty card :).

3D printers regardless of what brand or even type you choose will always require maintenance and or troubleshooting. ALL FDM printers will have a clog, jam or another issue at some point (not often with high-quality parts like the Prusa uses, and simply following best practices, but mistakes happen, like cooking the filament due to forgetting about it on a manual heat up or similar. Prusa has even gone so far as to help with that by recently releasing firmware to shut off the heater after an x minute timeout. Simply have a spare nozzle, foot of nice PTFE. a wire brush, and some alcohol

One thing we haven't mentioned is safety. This is an area that Prusa excels in as well. This goes back to the quality\design of the components and the countless hours of thought in design and coding in their firmware. Everything is top shelf and not some cheap copy of what someone else designed.

If you have the extra cash, the complete unit is worth it in terms of your time being spent (this kinda depends on the value of your time or enjoyment), but do not expect it to be flawless out of the box. This is not a Prusa issue but more of an international carrier one. They package the units as best they can, and care has been taken to ensure perfect delivery, but stuff happens. I have had at least two of my packages damaged in shipping by the carrier(physical damage to box), but it did not affect my kit in any way with exception to a rod slipping out of the packaging. I contact Prusa and had one in a couple of days. No problem. There is also a little-known side benefit to the complete printer, as it provides you with a discount for future parts and printers. You may have to verify that as I couldn't find the section.

Both printers and kit or completed form are under warranty for at least one year (2 in EU). I believe this covers all but normal wear and tear consumables. They have been fantastic in replacing any parts I received which either did not meet up with spec, were damaged in shipping, or failed due to nothing within my control, however I will state that I have several of them, and my first one purchased in November 2016 in indistinguishable in functionality from one only a few months old. I do take care of my equipment though, but in this case, it simply involves cleaning, retightening of belts, replacement of a bad nozzle, or a light lubrication of the friction surfaces.

Hopefully I have answered your questions. Good luck!

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Devdoc, many thanks for the tons of help and your time, it is much appreciated and has helped A LOT.

You covered my points/questions! It seems that the flexible steel build surface is worth it alone for the MK3. Am i right in understanding that you have to be very careful when removing prints from a MK2S in order not to damage the PEI sheet (or the printer itself) since the plate is not removable? And that the PEI sheet itself will be subject to replacement after some time? (following the procedure in the manual with the freezer and limonene).

With respect to print quality (of the MK3) if i am not mistaken most of the stuff i read, mentioned higher print quality on the MK3 than in comparison to lets say a CR10. So i suppose from all the printed samples i have seen (excluding the ones highlighted in "inconsistent extrusion" threads) i will be more than happy with the MK3.

Finally i suppose/hope that the issues discussed here (March 2018) are more or less resolved? (sorry for asking but i am still new here and still reading through old threads).

https://shop.prusa3d.com/forum/others-archive--f66/cancel-mk3-and-get-mk2s--t14883.html

Many thanks again!

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Why should the printed parts being components of the printer concern me in a professional setting? Reliability? They don't last long?

tolerance, consistency, and durability.

the entire hotend and x-carriage assembly is a perfect example of a design being way overcomplicated because it has to be printed and assembled. PETG is not an engineering-grade material.

dev is right and this could certainly work for you, but everything is a trade-off and its very likely that you may need to do some additional work to make it perform optimally for your application.

-The mk3 can be easily enclosed BUT... you've got to remove and relocate the PSU and reinforce the frame to do properly, otherwise risk blowing up the comically undersized PSU

-The e3v6 is the gold standard to hotends BUT... prusa handicapped it with a weak noctua fan and SS heatbreak

-The frame is relatively easy to assemble and square BUT... still nowhere near as rigid as anything like a corexy or a taz, etc.

-Smooth rods for linear motion on a printer in 2018 🙁 .....................

-The sensors and electronics are great, BUT... they're far, far, far from perfect

keep the limitations of your machine, your own tools/knowledge and FDM in general in mind and you'll be set.

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Curtis many thanks for the detailed reply.

The limitations you mentioned for the mk3, are in comparison to more higher-end machines, north of 1000$? (I am on a 750eu budget give or take here for a 1st printer at this stage.)

I am with you that any machine of any kind at any budget will have downsides and limitations, and you raise a valid (and important) point on the user being aware of these.

I am a bit confused here. In comparison to (cheaper in many cases) clones lets say, i am under the impression (based on what i read so far from various sources) that a Mk3 (or Mk2s) will have less issues, be more reliable, safe (print long hours unattended at home), and have higher quality, more consistent and more repeatable printing results. Isn't that the case despite the limitations you mentioned in your post? (printed parts, smooth rods, undersized psu etc..). The clones i mentioned do not have 3d printed parts etc...

Is the PSU indeed undersized on the mk3? I am after safety first here...

Based on the 24V heated bed, will i be able to print HIPS without an enclosure? I understand that for example a CR10 will not go above 85C w/o an enclosure, so HIPS is maybe a no-go in stock form. I mentioned this example as one of the key reasons for me leaning towards considering the Prusa (ability to print HIPS in stock form), not for comparing it to CR10 or discussing the CR10.

Thanks again!

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

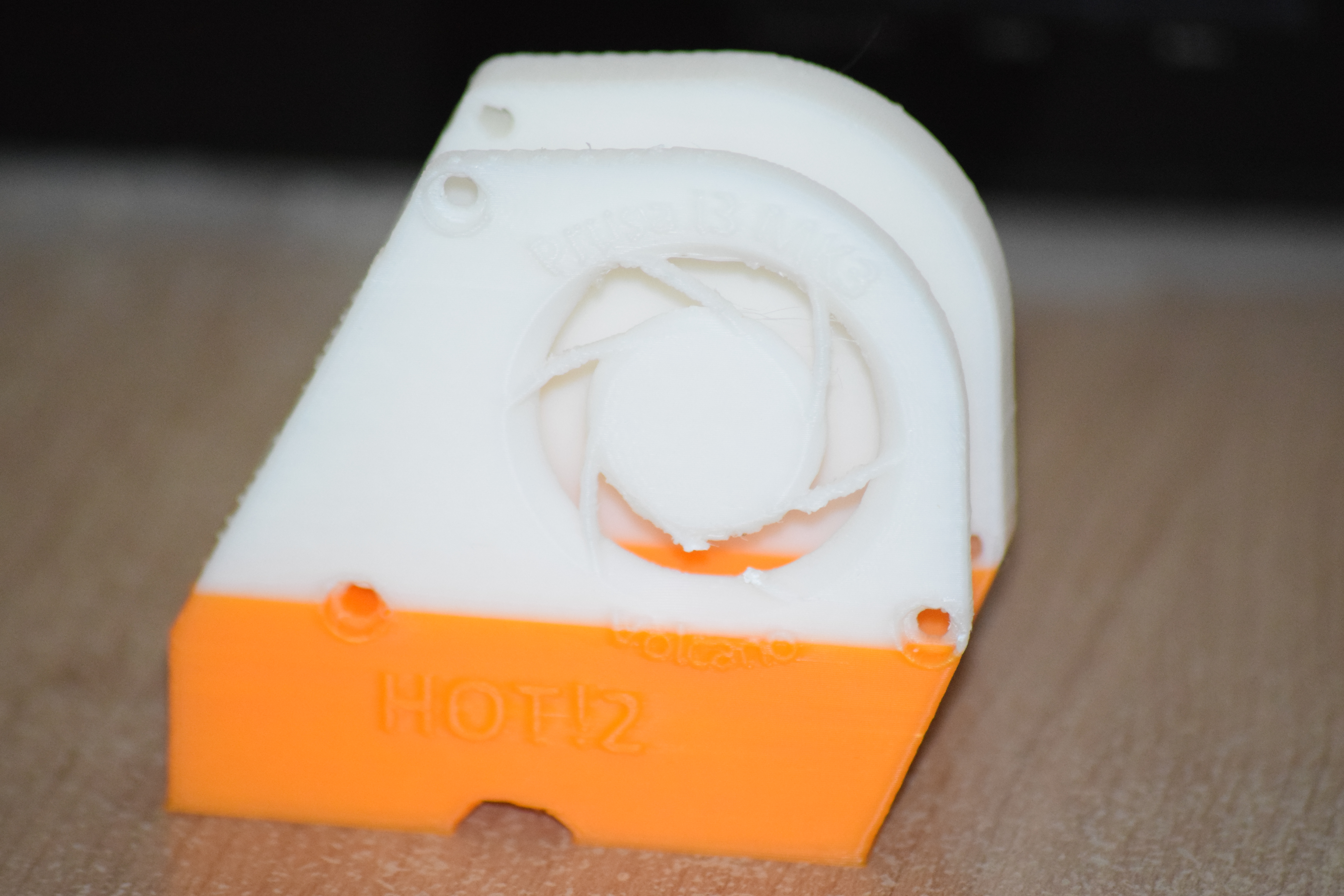

It is currently summer here in the UK and the ambient temperature in the room with my printer is 25°C. The following part was printed without an enclosure

The orange bit in the bottom was is 3DP Filament HIPS printed with the following settings:-

Nozzle: 0.4mm

Line width: 0.45mm

Layer height: 0.2mm

Nozzle Temperature: 220°C/220°C

Bed Temperature: 90°C/100°C

Print fan off for the first 3 layers then 20%, bridges at 50%

The white bit is Rigid Ink HIPS with a nozzle temperature of 230°C

The orange ran out which is why I finished the print in white. The piece of missing print is where I was not carful enough when removing supports. The filaments are not properly dialled in as I was using the previous version of the part to print it. However the only change I think I will need to make to the settings is adjusting the print fan. I think with slightly more fan I will get a cleaner result.

So in conclusion on a Prusa i3 MK3 it is possible to print in HIPS without an enclosure. Just limit the draughts and have an ambient of 21°C or higher.

Regards,

Martin

Martin Wolfe

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Dear Martin,

Thank you for the example on HIPS, it helped a lot! Small question, the heated bed temperature was set to 90C or 100C?

Inexperience question (Out of topic...) here... you can adjust fan speed etc... but when you say "Print fan off for the first 3 layers then 20%, bridges at 50%", what do you mean? Ok for setting it off for 3 layers and ok for then bumping up the speed to 20% what about the bridges comment? Excuse my ignorance for this question.

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

The bed temperature of 90°C/100°C indicates that for the first layer I had the bed at 90°C and at 100°C for the rest of the print. In general the first layer(s) of a print can have different settings for the rest of the print.

Now for the fan settings for the first three layers the part fan was turned off. Once those layers were complete it was turned on at 20%. A bridge is an unsupported span of extrusion. There are several in the example I posted. When bridging the filament needs to be solidified quickly so it does not sag hence the 50% bridge fan speed. The best example of a bridge in the example is the notch at the bottom of the print. The screw holes and the top of the air inlet are also examples of bridges.

Regards,

Martin

Martin Wolfe

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Thank you VERY much Martin for the explanations. Have you encountered any of this "inconsistent extrusion" when printing HIPS? From the picture you posted the surface quality looks very good given the layer height you posted. I take it the object is around 3-4 cm long?

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

The object is 7cm wide by 7cm tall by 8cm deep aprox. As I said I have not dialed it i properly as I was using a previous version to print it so any extrusion proplems were nt visiple not that I have noticed them in any of my prints in any of the materials I use.

Regards,

Martin

Martin Wolfe

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Thank you Martin for the follow-up, much appreciated. Just to confirm, that is out of a Mk3 right?

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Correct.

Regards,

Martin

Martin Wolfe

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Cheers Martin, thank you once more and have a good day!

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Devdoc, many thanks for the tons of help and your time, it is much appreciated and has helped A LOT.

You covered my points/questions! It seems that the flexible steel build surface is worth it alone for the MK3. Am i right in understanding that you have to be very careful when removing prints from a MK2S in order not to damage the PEI sheet (or the printer itself) since the plate is not removable? And that the PEI sheet itself will be subject to replacement after some time? (following the procedure in the manual with the freezer and limonene).

With respect to print quality (of the MK3) if i am not mistaken most of the stuff i read, mentioned higher print quality on the MK3 than in comparison to lets say a CR10. So i suppose from all the printed samples i have seen (excluding the ones highlighted in "inconsistent extrusion" threads) i will be more than happy with the MK3.

Finally i suppose/hope that the issues discussed here (March 2018) are more or less resolved? (sorry for asking but i am still new here and still reading through old threads).

https://shop.prusa3d.com/forum/others-archive--f66/cancel-mk3-and-get-mk2s--t14883.html

Many thanks again!

In regards to the PEI sheet on the MK2, you should be carefull, but not neurotic. Basically a rounded/deburred spatula/putty knife works fine and will last a long time if simple cleaning and common sense is practiced. Replacing the sheet indeed involves a freezer and limonene, or a thousand other homebrew ideas you can find online. That 3M adhesive is amazing. It is a bit of a painful process to be honest, but certainly doable, just not worth it once you have tried the MK3 system. I am not even certain I will replace the PEI on the spring steel sheets given the price they are offering the new double sided ones for. It costs an additional $10 as opposed to doing it yourself, but both sides of my MK3 sheets are fine and should last a long time. Funny point to note is that I found peanut butter to be my best solution for the heavy work of sheet replacement, followed up by acetone and isopropyl alcohol.

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Thank you devdoc,

Based on the help from all the fellow members in this thread (and by reading relevant threads here) I have decided in favor of the MK3 (to the MK2S)!

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

Congratulations on your decision. I am certain you will be happy with your choice. I am building another of my kits today and am just as excited as my first. We look forward to seeing you on the forum with your new printer once you get it. It's a great community.

Re: Choosing a MK3 (or a MK2S), questions (prototyping with HIPS)

I agree with Dev. I own an Mk2S that I have had for 7 months now and if I were buying my first I would hands down go for the Mk3. I am even considering buying the full upgrade kit or just buying taking the plunge and buying a second printer. You will not regret the Mk3 and good luck on your endeavors!