Anyone have any tips on how to fix this

So I just got my MK3, and was able to put it together yesterday. Every last print I make is coming out bad. I've changed the first layer to make the test look near exact to what is in the video. I tried multiple files, and so on.

I have a video of it and extra pictures here

https://photos.app.goo.gl/xL3AxjDWMUjRFyD76

Re: Anyone have any tips on how to fix this

Is that a genuine Prusa? My bed doesn't look like that at all.

Re: Anyone have any tips on how to fix this

Is that a genuine Prusa? My bed doesn't look like that at all.

Mine does.

Re: Anyone have any tips on how to fix this

Cool. Mine's just like the store page one. Wonder why that changed...

Well in that case, and judging by the "perimeter" which is inconsistent I'd say there's an extrusion problem and possibly the nozzle is too high on layer 1 (the bottom layer should be basically solid, not with gaps between each stroke).

Are you using the correct gcode for your firmware? If you've updated the firmware, ditch the demo files on the SD card that came with the printer.

Then move on to the extruder. Is it clicking? Are the tightening screws tight enough?

Re: Anyone have any tips on how to fix this

possibly the nozzle is too high on layer 1 (the bottom layer should be basically solid, not with gaps between each stroke).

Are you using the correct gcode for your firmware? If you've updated the firmware, ditch the demo files on the SD card that came with the printer.

Then move on to the extruder. Is it clicking? Are the tightening screws tight enough?

The first layer test looks like the one on the prusa video.

I'm using the demo files. Even when using my own models I made, I'm getting similar things.

There is no clicking, but I found some white dust inside where the filament comes in. I'm still on the prusa stuff. Could this been caused by the nozzle. Like if I accidentally messed it up somehow?

I took a video of the test https://photos.app.goo.gl/xL3AxjDWMUjRFyD76

Re: Anyone have any tips on how to fix this

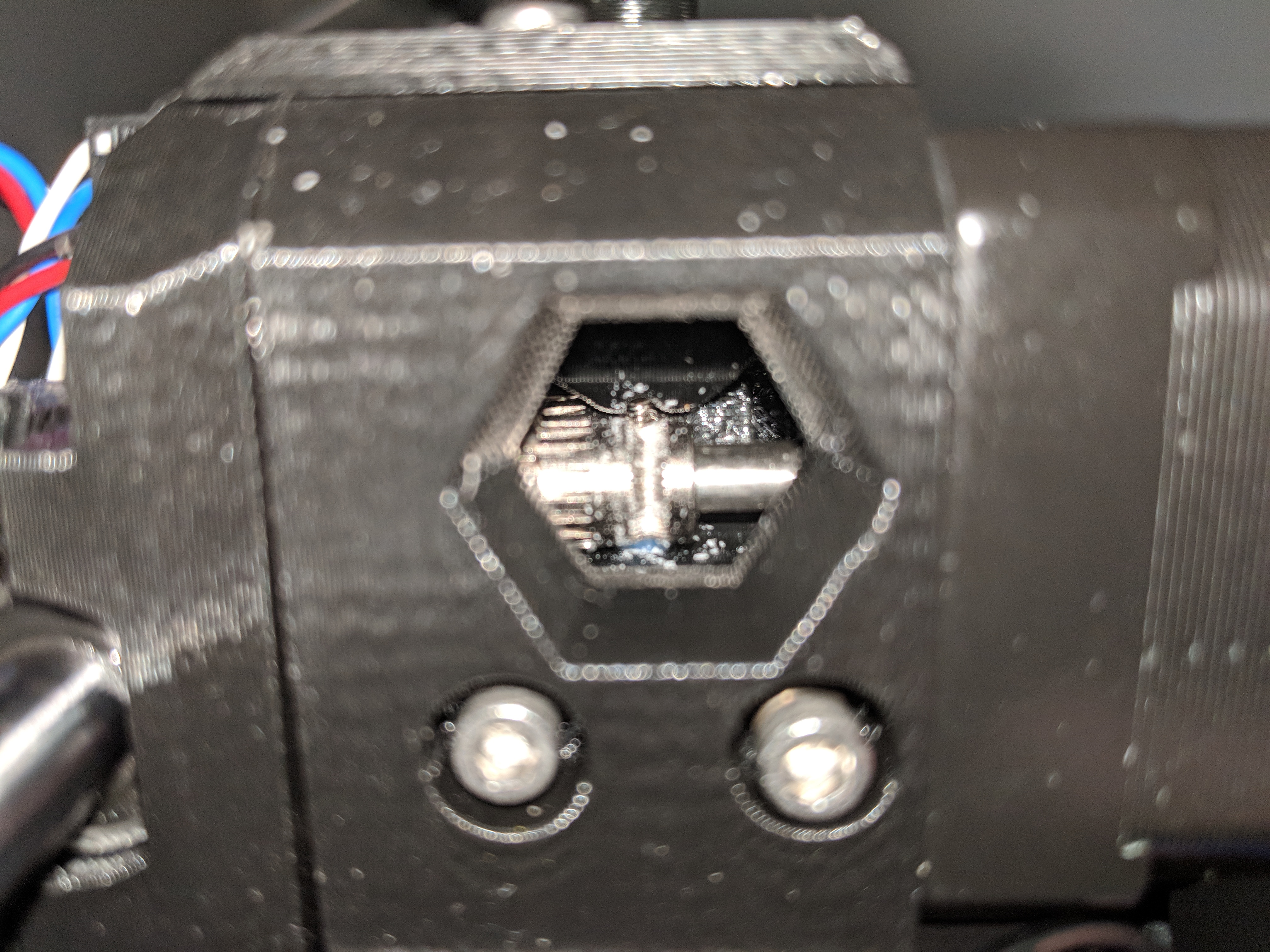

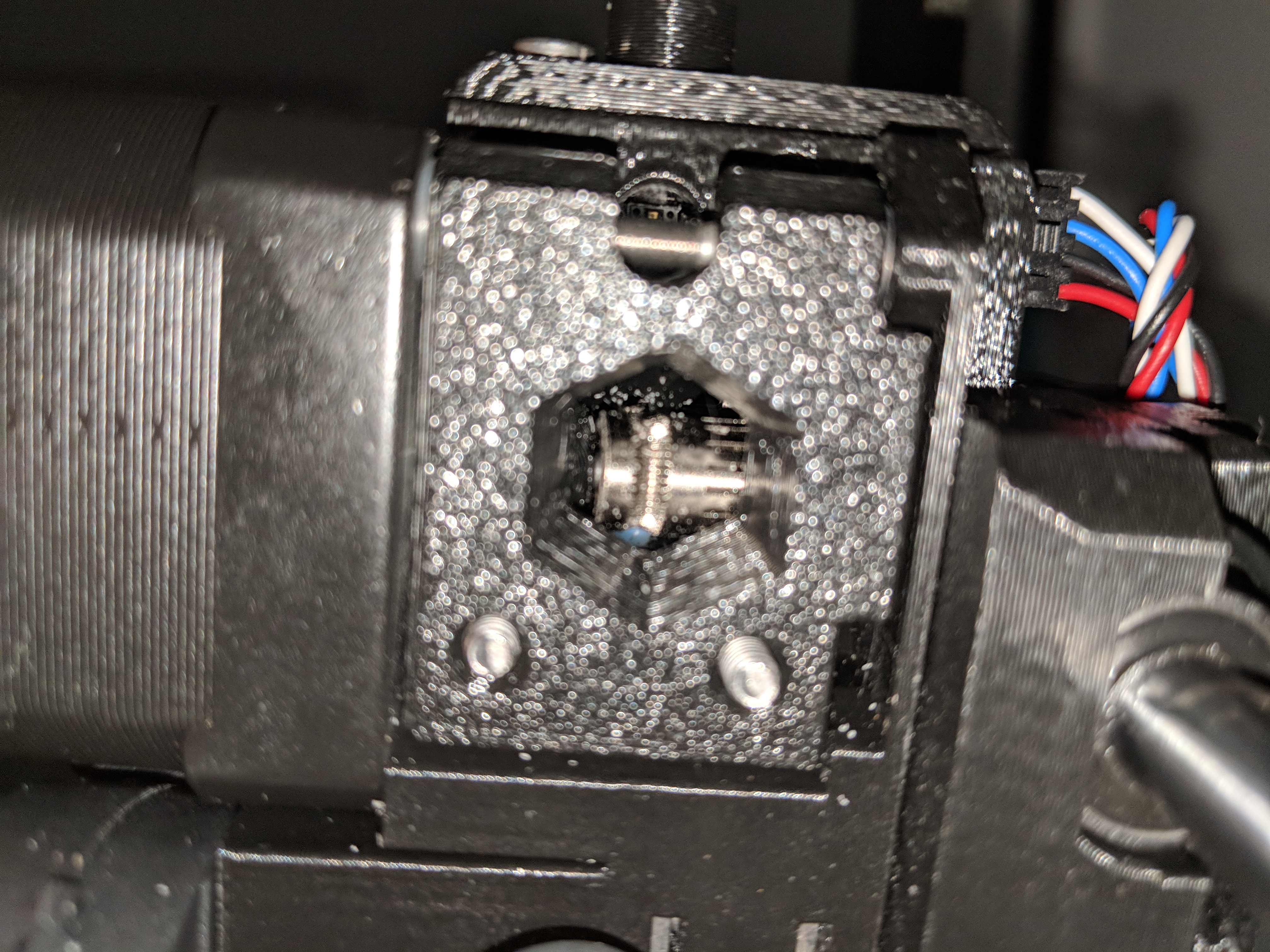

The idler cover looks too flat - it should be at a slight angle. Check with the manual if the Bondtech gears are installed correctly and that you used the right one (one with the set screw) on the motor and the setscrew is tightened against the shaft. Make a picture of the opened idler so we can see both gears 😛

If you try and take a cat apart to see how it works, the first thing you have on your hands is a nonworking cat.

Re: Anyone have any tips on how to fix this

Seems like a extrusion problem caused by too much/too little tension on the gears. The white dust might be ground up filament. Loosen/tighten the screws a bit and see if it improves. Make sure your gears are aligned with the filament holes. Additionally, your X belt seems misaligned and twisted (and probably too loose). I would fix that as well.

Re: Anyone have any tips on how to fix this

Seems like a extrusion problem caused by too much/too little tension on the gears. The white dust might be ground up filament. Loosen/tighten the screws a bit and see if it improves. Make sure your gears are aligned with the filament holes. Additionally, your X belt seems misaligned and twisted (and probably too loose). I would fix that as well.

The pulley gear for the X axis is installed the wrong way around (common mistake, but do fix it) 🙂

Re: Anyone have any tips on how to fix this

The idler cover looks too flat - it should be at a slight angle. Check with the manual if the Bondtech gears are installed correctly and that you used the right one (one with the set screw) on the motor and the setscrew is tightened against the shaft. Make a picture of the opened idler so we can see both gears 😛

Well the thing is broke. I'm to the point of saying I regret getting this printer. Between putting it together and going through 16 hours of trying to fix this. If I had the same consumer protections as they do in Europe I would be looking at returning this and seeing if they can just send me a fully made one so we can eliminate that from the possible problem list.

And what really sucks is I was ready to fully endorse this on my YouTube channel by making an entire new line of videos to teach people about 3D printing. But after spending maybe 16 or so hours working on this problem, I'm ready to throw my hands up on this

{rant over}

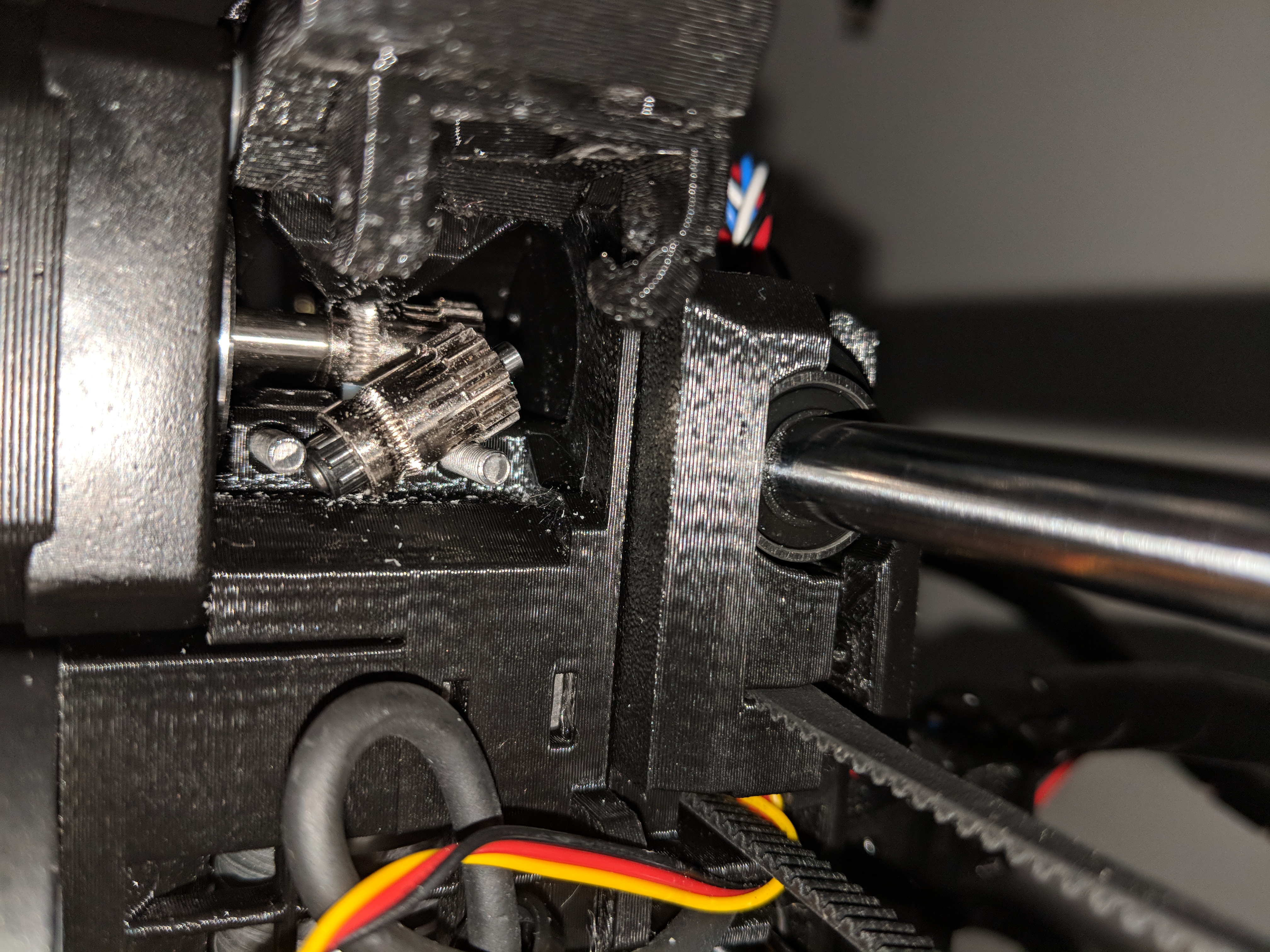

The part that is broke is the black thing that comes up, one of the things you had to slide the rod into is broke

I added the pictures

Re: Anyone have any tips on how to fix this

Contact support, explain what happened and hopefully they will help you.

The idler door is a cheap part, the model of the part is available for free on the internet - if you have anyone in the area with a 3d printer you can ask them to print one for you, if not you can order it from Prusa directly.

Don't give up just get the part and reassemble the extruder paying close attention to the instructions (there are few errors in your assembly - i't easy to make them after many hours of putting smal things together). I also had quite a few issues with my first 3D printer but 3D printing is too fun to give up on it that soon!

If you try and take a cat apart to see how it works, the first thing you have on your hands is a nonworking cat.

Re: Anyone have any tips on how to fix this

Contact support, explain what happened and hopefully they will help you.

The idler door is a cheap part, the model of the part is available for free on the internet - if you have anyone in the area with a 3d printer you can ask them to print one for you, if not you can order it from Prusa directly.

Don't give up just get the part and reassemble the extruder paying close attention to the instructions. I also had quite a few issues with my first 3D printer but 3D printing is too fun to give up on it that soon!

I don't have anyone in my area that i know of with a printer. I would've had them over because it was rough putting this together. I contacted support about the filament checker, and I will see if I can get them on chat tomorrow about this.

The more I mess with it the more problems come up. Let it for some reason forgot all the settings I had on it, and any time something happens or if I turn it off then on later, it will think it's in the auto home area giving it wasn't before.

The biggest thing I wish I did was just buy the entire unit pre-built. I don't think this was worth no saving $200-$300

Re: Anyone have any tips on how to fix this

Some libraries have printers,

Hacker spaces and maker spaces often have printers,

and there is 3D hubs https://www.3dhubs.com/

or alternatively, if you let us know where you are, one of the forum members may be able to help you...

regards Joan

I am in Halifax UK!

if that's any help.

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Anyone have any tips on how to fix this

I'm in Western PA and will print off a part for you if you need.

Re: Anyone have any tips on how to fix this

I'm in Seattle and would be happy to print out a replacement part in PETG for you. Let me know. Once you get it all together and tuned nicely, it's a very reliable and solid printer that makes good quality things.

Re: Anyone have any tips on how to fix this

Some libraries have printers,

Hacker spaces and maker spaces often have printers,

and there is 3D hubs https://www.3dhubs.com/

or alternatively, if you let us know where you are, one of the forum members may be able to help you...

regards Joan

I am in Halifax UK!

if that's any help.

I'm in the country. I know none of the libraries have this near me, and the nearest one to me is a 1 way 15 min drive. I don't know of any maker spaces or anything like that around me. I actually thought about making one giving I can learn how to print.

I'm in Western PA and will print off a part for you if you need.

I'm in Seattle and would be happy to print out a replacement part in PETG for you. Let me know. Once you get it all together and tuned nicely, it's a very reliable and solid printer that makes good quality things.

I just talked to support, and they are sending me another part. Right now I super glued it, and they mention my belt is too tight. So once I fix that I will test it out. If I can get it working for a day or so, then I will print myself out one since I have PETG black still in the box.

Re: Anyone have any tips on how to fix this

Best of luck,

Maybe you could start a makerspace near you!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK