Re: Any response from Prusa on the inconsistent extrusion?

Do all direct drive extruders, including the Titan, have this problem?

i'm going to say not exactly, no..... my first machine was a makerfarm with direct drive (40mm nema and mk8 gear), when i re-look at some old prints with that machine it seems fine, sure the layers aren't perfect like most machines and the fact it used M5 rods instead, there's no weaving or moire and each layer appears consistent to itself. there was no LA used on these but seems pretty good to me.

it also went from titan, to titan aero with volcano nozzle and it appears to print pretty good.

Re: Any response from Prusa on the inconsistent extrusion?

[...] This is Hatchbox PLA and a printer fairly close to stock with fairily stock settings. I cannot find the basket-weave surface on this cylindrical part though I have seen this on other parts.

What variable should I change to try to _cause_ the problem. You don't have to do anything. Print in a high-gloss black or silver for best contrast, although you'll see it in any glossy surface. Hold the part horizontally under direct light from above so no light is shining on the vertical surface that printed as the side of the object. Make sure it's oriented so the sides are aligned as printed. Now slowly rotate the object back until the light starts to pick out lines. On a cylinder, it's going to be hard to see the side-to-side inconsistencies, but you will see some layers popping out more than others and you may see some of the un-evenness from side-to-side. It's a lot easier to see on flat surfaces printed with the same parameters.

That test may narrow something like root cause. One thing I noticed is that since this was only a single wall it becomes the one and only 'outside' so the entire print runs at low speed.

Look at the cubes I posted pics of previously. Those were all single outer perimeter prints with no infill. You do get less of an effect with vase mode, but it's still there.

this print had no corners, no infill, all low speed. I was thinking I should add a corner or two to this part and see if this causes linear advance to kick in and for more interesting things to happen.

You can, but keep in mind that Prusa is already running with the issue. We're just having fun here. I see it on every part I print, regardless of size.

Here's a recent print I did for testing. If someone had told me 4 months ago I'd be able to print with this quality with no experience, I'd have been thrilled:

Not perfect by any means, but a pretty decent print. Ah, but now we're looking for the issue. Change the lighting and you get:

Same print is now crap, and some guys $200 printer does better, lulz. It is very subjective. Like I said, it's like Megan Fox's thumb. If you want to find imperfections, you can. Taken from a distance, they're pretty minor.

I did finally find examples of print quality on some of the other printers that the Prusa Mk3 is being compared against. Check out this video. Ignore the thumbnail of the scrawny shirtless guy (why the hell did he think THAT was a good idea?) and watch the Alphawise U20 and CR-10 examples carefully. Throughout, he is praising the print quality on both. Now if you pause at a good point, you'll see something like:

Better? The lighting is difficult and the images blurry, but what I'm seeing confirms what I've read. The crispness of the Mk3 makes these defects pop. On these others -- at least in this example -- the overall print isn't as sharp, so naturally, surfaces don't catch light the same way. I'm not saying there's not an issue that can't be improved. I'm just remaining very skeptical of the claims of "smooth as a baby's backside" praise for some of the others in comparison.

I've yet to see an objective comparison photo of the Mk3 against others with both samples held in identical lighting at identical focus. No funny shadows over one or the other, so slightly different angle. Same print, same light, same angle.

Verigo grey? that's fairly virgin pure PLA like rigid.inks and usually prints very well... add glitter and it's even better. most other PLA's won't print this well from my experience. its one of the best, along with marble and maybe Carbon fiber infused filaments. CF-Nylon being really good at hiding even the layers completely. some of those could be slicer path/cooling related..... the inconsistent extrusion is very specific and even with that fixed prints could still look like this for other reasons.

Re: Any response from Prusa on the inconsistent extrusion?

Considering how subjective this one is, I'd be curious to see where it ranks in their priorities. It may be in the "urgent but not important" category compared to other issues.

probably LOW - Compared to say, making an SLA machine instead, filament and MMu.... seems like they're adding more products to their lineup while still keeping insane lead times.....

^This. I'm just glad I'm not one of those who are waiting on pins and needles for a solution.

Re: Any response from Prusa on the inconsistent extrusion?

I just printed a little cylinder vase-like part and I sliced it with the special mode for single-wall parts.

This is Hatchbox PLA and a printer fairly close to stock with fairily stock settings. I cannot find the basket-weave surface on this cylindrical part though I have seen this on other parts.

What variable should I change to try to _cause_ the problem. That test may narrow something like root cause. One thing I noticed is that since this was only a single wall it becomes the one and only 'outside' so the entire print runs at low speed.

this print had no corners, no infill, all low speed. I was thinking I should add a corner or two to this part and see if this causes linear advance to kick in and for more interesting things to happen.

That's an interesting result. Perhaps it has something to do with either jerk or acceleration or maybe even just speed? On a cube the speeds can get higher than on a similar sized cylinder, since the straight lines allow for continued acceleration in just one direction, whereas on the cylinder it's constantly varying.

Or maybe there's enough noise on a cylinder's surface anyway that it effectively hides the effect.

As to linear advance, I don't believe it's automatic. Rather, it's a number you have to explicitly set using gcode.

there isn't much noise on the surface of the cylinder, its really nice - nicer than some of my other good prints. Linear advance is active because of the profiles and start G-code that Prusa put in there - at least last time I checked.

I think you have a very good point about jerk and acceleration which in my mind points to firmware and driver interactions being at play - but of course what else would it be? ; )

btw, bobstro I do know how to find the defect that we are are looking at - as I have been able to find this on most of my prints. I have a 10X stereo microscope at home and at the office and use an LED flashlight to shine light at a low angle but 90 degrees to the filament layout. I looked around this cylinder and could not find the basket-weave.

Re: Any response from Prusa on the inconsistent extrusion?

I'm not surprised. It's going to be hard to spot on a cylinder by nature I'd think! Pictures would be great.

[...] I looked around this cylinder and could not find the basket-weave.

I've done a series of tests with this shape on Thingiverse. I printed a series of 8 with Slic3r with Prusa's LA and other settings:

1. Perimeters: 45mm/s, external perimeters 35mm/s, acceleration @ 800mm/s^2, jerk 10 (defaults)

2. Perimeters: 30mm/s, external perimeters 25mm/s acceleration @ 1000mm/s^2, jerk 10

3. Perimeters: 30mm/s, external perimeters 25mm/s acceleration @ 1500mm/s^2, jerk 8

4. Perimeters: 45mm/s, external perimeters 35mm/s acceleration @ 800mm/s^2, jerk 8

5. Perimeters: 45mm/s, external perimeters 35mm/s acceleration @ 1500mm/s^2, jerk 8

6. Perimeters: 30mm/s, external perimeters 25mm/s acceleration @ 2000mm/s^2, jerk 6

7. Perimeters: 45mm/s, external perimeters 35mm/s acceleration @ 1500mm/s^2, jerk 6

8. Perimeters: 45mm/s, external perimeters 35mm/s acceleration @ 800mm/s^2, jerk 6

Edit: I increased acceleration after watching an excellent video on surface finish (not Prusa-specific) that noted that reducing acceleration can result in more material being deposited in corners as the extruder slows. He suggested printing perimeters slower, but increasing acceleration.

I discretely marked each one on the underside and jumbled them up. I then went through and scored each cube on each side on a scale from 1-5 for overall finish. I totaled them up and... the default settings yielded the best overall finish. Others were a bit cleaner on one feature or another, but the defaults gave the most consistent results. None really made an impact on the extrusion issue. Being so small, these may not have been a good test for this specific issue.

I'm increasingly convinced this hobby leads to compulsive behaviors. Anybody else will just see a guy hunched over a bunch of tiny cubes.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

The inconsistent extrusion is clearly related to the bondtech gears as well as a number of other issues. Standard FDM artifacts related to print speed / jerk / acceleration aren't what is being discussed here.

I will agree though people shouldn't be losing too much sleep over this ... I bought a mk3 both before and post 602.

Re: Any response from Prusa on the inconsistent extrusion?

Understood, and to be clear: I was doing overall surface quality tests, not explicitly testing for the inconsistent extrusion. I did want to note, however, that trying a variety of settings that otherwise affected surface quality didn't make any perceptible difference on this issue. I think all of the slicer-adjustable settings have been beaten to death and eliminated from consideration elsewhere.

The inconsistent extrusion is clearly related to the bondtech gears as well as a number of other issues. Standard FDM artifacts related to print speed / jerk / acceleration aren't what is being discussed here.

I will agree though people shouldn't be losing too much sleep over this ... I bought a mk3 both before and post 602.

I've moved past the "trying to nail it down on the Mk3" more towards "just how bad is (or isn't) this issue on other printers". If you look at the 2 gray cubes in the Thingiverse pics I put up earlier in this thread, it's interesting (to me anyhow) that you still see the same color gradations though not ridges on vertical walls of the CR-10 print. Are those due to muted shadows due to a softer variation (less edge to reflect)? The other YouTube grab pics certainly hint at this. Any good pics I've seen from other printers show similar "mushy" lines. Would love to see a good side-by-side lineup.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I do think 2 things are compounding the problem

1) prusa sends silver filament which is probably one of the worst for showing defects

2) creality is just really nailing it print quality wise and for pricing most countries can't dream of touching. vwheels when they work are very smooth for the price and bowden is quite forgiving aside from retraction and feeding issues (A mk3 with bowden prints much better but acquires the bowden downsides).

Re: Any response from Prusa on the inconsistent extrusion?

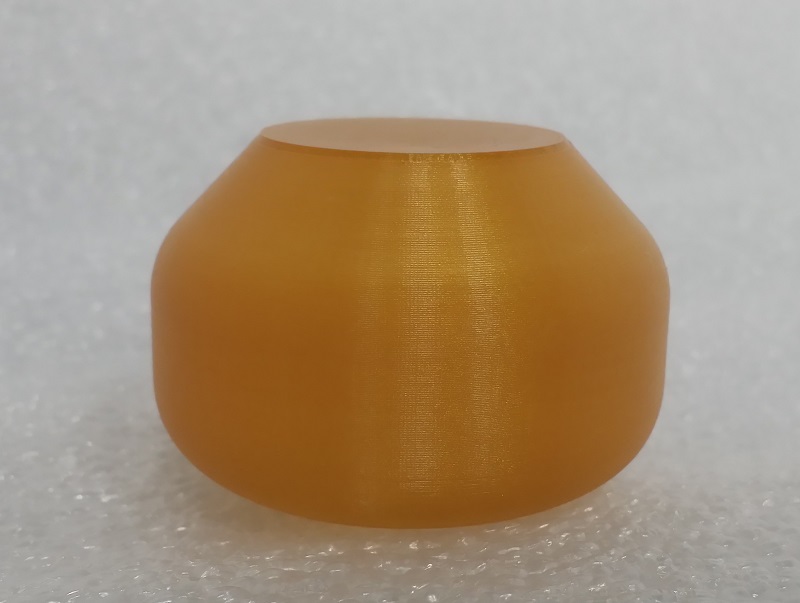

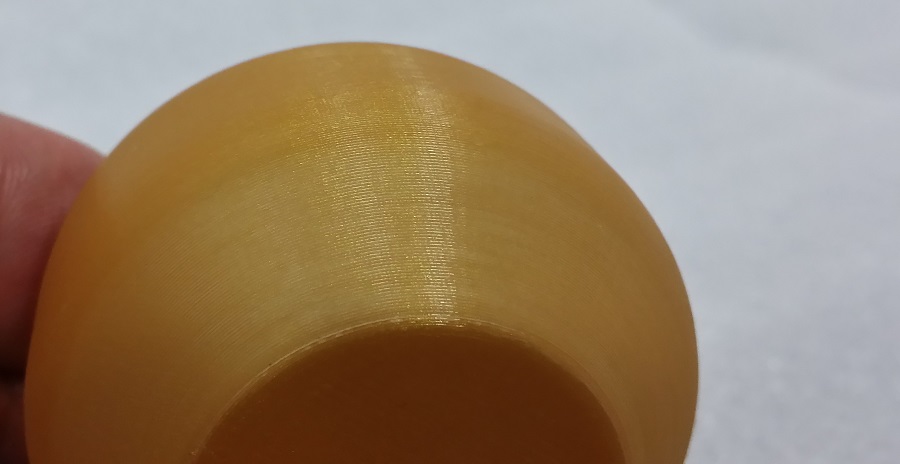

these pictures reference an earlier post. I am doing a series of test parts for comparison of round parts to flat (corners vs no corners) and with infill versus using the spiral vase mode. so far, parts made with spiral vase mode look quite nice and maybe it is only due to the slow speed?

These are all on Prusa MK3, PLA material 0.15mm layer height

overall part looks nice to the naked eye. Its around 40mm diameter at the largest

It is hard to get a perfect picture. I have viewed the part with an extra LED flashlight shining at a shallow angle and also under two different 10X stereo microscopes and I cannot find the basket-weave affect.

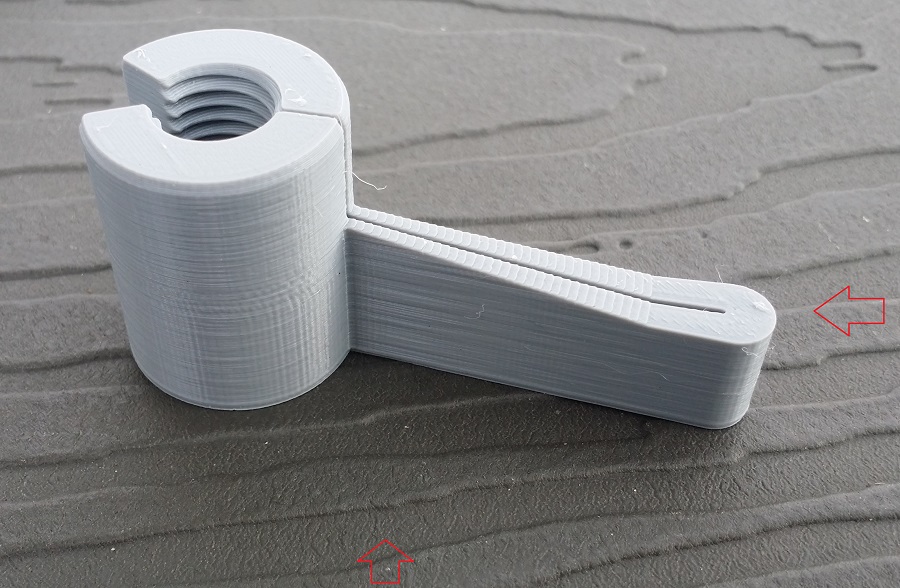

Following is a different, more typical part with infill and one that I think shows the basket-weave pattern near the intersection of the red arrows. for my purposes it's a really nice part so I don't care about the fact under certain lighting it looks this way. For scale, this part is an M12 nut.

I'm away from good internet from the weekend and I find anything interesting will post back later. again, what I'm looking for is particular moves that trigger the affect vs moves that do not obviously for the purpose of helping to find root cause.

[Edit].... realized i should start my own thread for this.. will do that to avoid hijacking to go on this tangent

Re: Any response from Prusa on the inconsistent extrusion?

Hey Jo, how's the blog post coming along?

Re: Any response from Prusa on the inconsistent extrusion?

Posting my results here.

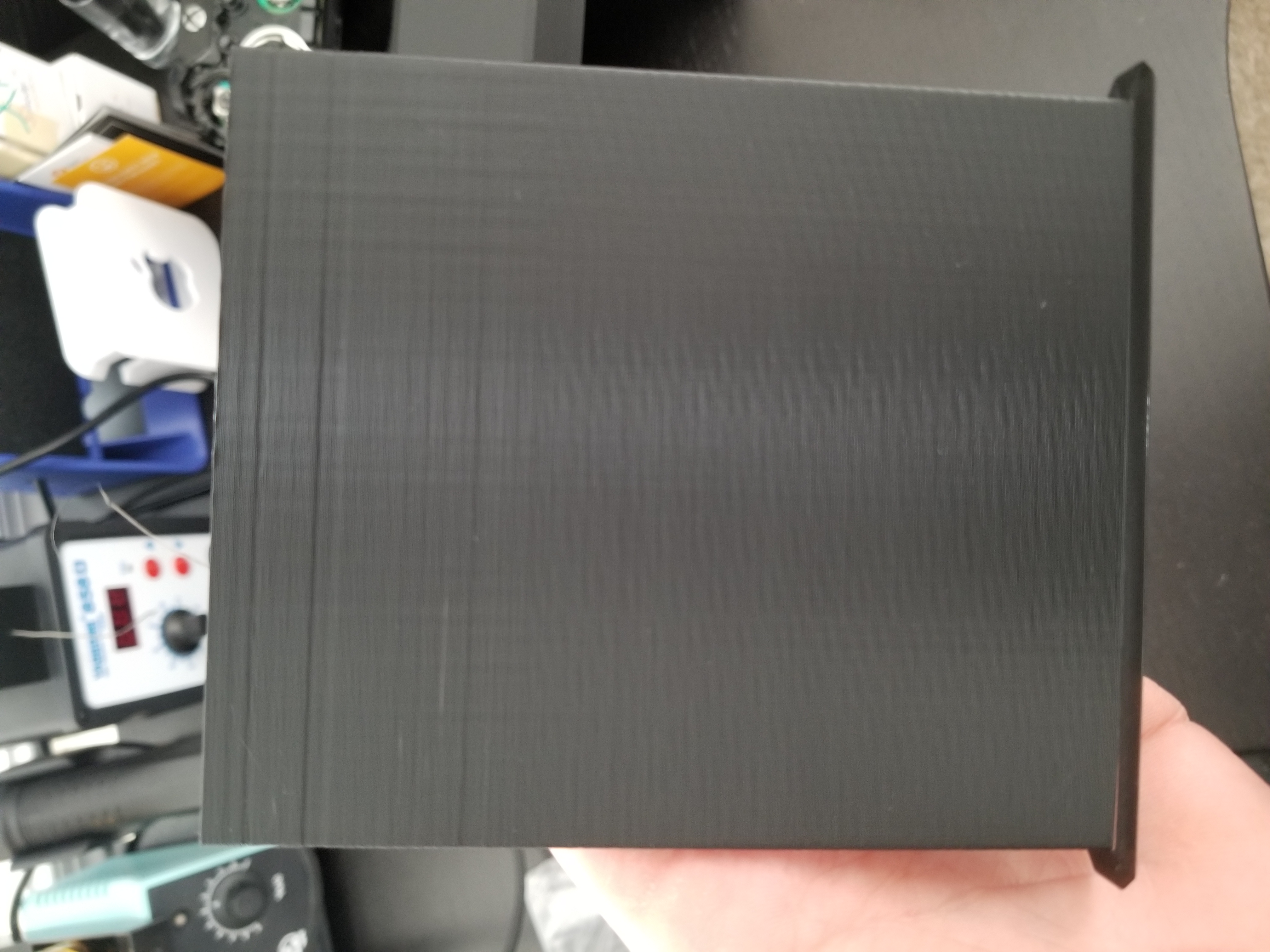

Here's a test print under normal room lighting and looking directly at the print:

Here it is from an angle:

After watching Tom's YouTube video I should just accept that this is just FDM printing.

Re: Any response from Prusa on the inconsistent extrusion?

If that's a flat surface, you've got some other issues going on near the top.

[...] After watching Tom's YouTube video I should just accept that this is just FDM printing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

If that's a flat surface, you've got some other issues going on near the top.

[...] After watching Tom's YouTube video I should just accept that this is just FDM printing.

I was a tall and narrow print so I imagine the print was shaking as it started to get to the top. I'm not concerned with that I was concerned with the basketweaving pattern.

Re: Any response from Prusa on the inconsistent extrusion?

I was a tall and narrow print so I imagine the print was shaking as it started to get to the top. I'm not concerned with that I was concerned with the basketweaving pattern.

It's not a bug, it's a feature 😉

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Any response from Prusa on the inconsistent extrusion?

It's not a bug, it's a feature 😉

The Apple of 3d printers: "You're printing with it wrong"

Re: Any response from Prusa on the inconsistent extrusion?

Posting my results here.

Here's a test print under normal room lighting and looking directly at the print:

....

it's pretty interesting because I've seen the same look but not all the time. It feels to me like the mechanism can make straight lines but the ... is the software messing up in some situations...

is that part anything special or secret? would you care to share the gcode or stl? I'd be curious to print it. I've got a set of parts that are all done with spiral vase mode and the surface looks great even when I speed up the printer. On solid parts with infill I get various results and am having a hard time pinning down the difference. a thing to try would be the same part you just did except build it as a spiral vase with single outer wall and see if it is smooth.

Re: Any response from Prusa on the inconsistent extrusion?

is that part anything special or secret? would you care to share the gcode or stl? I'd be curious to print it. I've got a set of parts that are all done with spiral vase mode and the surface looks great even when I speed up the printer. On solid parts with infill I get various results and am having a hard time pinning down the difference. a thing to try would be the same part you just did except build it as a spiral vase with single outer wall and see if it is smooth.

Here you go. It's just something I quickly modeled with fusion360.

STL: https://www.dropbox.com/s/kntarsrbw0gtlex/Test%20Object.stl?dl=0

GCODE: https://www.dropbox.com/s/j339uwpq51fa5ii/Test%20Object.gcode?dl=0

Please post your results so I can see how it came out on your printer. Thank you!

Edit: with the gcode I provided I printed it with 2 perimeters and 20% infill. Yeah, it's a waste but I wanted to see how it would print with my default slicer profile.

I'm printing a new one with 1 perimeter and 0% infill; I'll post the results when done.

Also, you're going to have to rotate the test model on your printer bed. I chose the wrong plane when I modeled it.

Re: Any response from Prusa on the inconsistent extrusion?

Have you run through the Extruder linearity correction calibration process. That may help with some of that patterning you're seeing.

The inconsistency is very real on the Prusa printers... and apparently others using the same hardware, depending on who you talk to. FDM inconsistency is also very common on all printers, although it's damned hard to find comparable photos. Do you have an example photographed in similar light that you're aiming for?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

Here you go. It's just something I quickly modeled with fusion360.

STL: https://www.dropbox.com/s/kntarsrbw0gtlex/Test%20Object.stl?dl=0

GCODE: https://www.dropbox.com/s/j339uwpq51fa5ii/Test%20Object.gcode?dl=0

What do you suppose the odds are that we can get someone with another printer to print this for an objective comparison. Ideally, we'd be able to see a similar photo using similar filament in similar light. Otherwise, it's a contest to see how bad a picture you can take, and I should be able to win that one!

Please post your results so I can see how it came out on your printer. Thank you!

I'm tied up with a big print tonight, but I'll see if I can print it later this week. However, I can tell you that in that light, it's going to look very similar. The question I have is the same print it will look with any other printer in similar circumstances.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

What do you suppose the odds are that we can get someone with another printer to print this for an objective comparison. Ideally, we'd be able to see a similar photo using similar filament in similar light. Otherwise, it's a contest to see how bad a picture you can take, and I should be able to win that one!

Pretty good actually. I've reached out to my buddy who's going to print the same object on the CR10.

Regarding the extruder linearity correction, I've already printed the tower and that print is with the max E correction value in accordance to how I should adjust it according to Prusa's material.