Re: Any response from Prusa on the inconsistent extrusion?

I posted it a few comments back as well, but did not see a comment from anyone. Is built up twist tension in the filament a possible source of the variability? uilding, relieving, building, relieving, etc, as the filament moves through the gears?

I proposed a simple experiment to test: remove a long enough length of filamet off the spool so it wont twist while being sucked into the extruder, and see if the print quality changes. Maybe I will try now....

edit: I just tried a print with loose filament supply, and no change, same basketweave pattern. The print still looks good to my eye, and I dont consider it a problem. If it can be improved I would improve it, if it cant, no big deal either.

Since you're able to see a basketweave pattern, how about also trying the idler tightening and loosening experiment? I'm not using PLA these days, so I'm not rigged for it.

Re: Any response from Prusa on the inconsistent extrusion?

The standard filament spool holder has no bearings and sits above the machine. The extruder and gears have to pull the filament off this spool which might be heavy - or light obviously depending how much material is left.

The rigidity of the extruder in the Z-direction is quite low. Is it possible that the artifacts are caused by the nozzle moving up and down as it tugs on the spool to drag more filament out? This may not be root cause for the smallest of defects that require special light to see but I think it could be causing some of the large defects.

I have my filament spool off to the right of the machine and the spools run on ball bearings in hopes to alleviate this.

[edited]

I was never really disappointed with my prints and am only interested in this because I keep hearing so much about it. I can still find basket weave appearance in my prints but without that special lighting the prints are really good. When I looked closely at prints from my older Printrbot i also noticed bad surfaces. I am curious about the idea of the MK2 having superior quality non-basket weave prints - to what extent is there a step-change difference?

I am not spending time doing comparison prints - just making parts for my projects.

[end edit]

Re: Any response from Prusa on the inconsistent extrusion?

I have my filament spool off to the right of the machine and the spools run on ball bearings in hopes to alleviate this.

Did you notice any improvement after doing that?

Re: Any response from Prusa on the inconsistent extrusion?

I have my filament spool off to the right of the machine and the spools run on ball bearings in hopes to alleviate this.

Did you notice any improvement after doing that?

I've moved my filament off the top of the frame onto a roller stand with bearings positioned directly behind the printer. I use a filament guide with a bearing mounted atop the frame, so the filament feeds up from behind, over the frame, then directly down to the extruder.

At the time I changed, I didn't notice a big difference, but looking at my early 20mm cube (shown in my previous post), newer prints are cleaner. Not so much from this extrusion issue, but overall surface quality is noticeably better. At some point, I'll try slapping the frame-top stand back on.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any response from Prusa on the inconsistent extrusion?

I suppose a simple test would be exactly like the one performed to check for twist: cut enough filament off the spool to do a print and see if the outcome is better. I guess if anyone is truly serious about this, then that would be an very easy test to run.

Re: Any response from Prusa on the inconsistent extrusion?

If you mount a dial indicator onto the extruder and touch the top frame you will see a change in height on the z-axis with the nozzle near the bed. I have my filament reel on the desktop roller holder with a 3mm Bowden tube feeder tube to the extruder. I prefer this setup over the stock MK3 reel holder that wiggles and shakes with the fast machine moves.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Any response from Prusa on the inconsistent extrusion?

I have my filament spool off to the right of the machine and the spools run on ball bearings in hopes to alleviate this.

Did you notice any improvement after doing that?

NO.

I did a print today that had a cylinder of 48mm diameter and I switched my filament reel setup mid-way through. I cannot find a difference on the cylinder. The print is fine for all purposes that I have and I can only find the basket weave by taking the part to my 10X stereo microscope and shining the light at a low angle.

What I think I am seeing may not even be the extruder's fault. To me it looks simply like the 'X' or the 'Y' positions are varying and this can be easily explained as backlash in the machine. I'ts not surprising at all that a machine built this way would have imprecise movements so what's got my curious is why so many people state the MK2 did not have this problem. What is different in the two machines?

- 24V system

- new control board - specifically the driver chip

- new firmware

- new heatbed - is this one significantly more heavy than the other one due to the spring steel and magnets?

- different extruder traction system.

- are there other significant differences?

I don't have an MK2 and have never seen one in real life

Re: Any response from Prusa on the inconsistent extrusion?

I have my filament spool off to the right of the machine and the spools run on ball bearings in hopes to alleviate this.

Did you notice any improvement after doing that?

NO, not for this issue. I still think the layout is a better way to go but it doesn't appear to be the root cause for the surface imperfections that I find.

I did a print today that had a cylinder of 48mm diameter and I switched my filament reel setup mid-way through. I cannot find a difference on the cylinder. The print is fine for all purposes that I have and I can only find the basket weave by taking the part to my 10X stereo microscope and shining the light at a low angle.

What I think I am seeing may not even be the extruder's fault. To me it looks simply like the 'X' or the 'Y' positions are varying and this can be easily explained as backlash in the machine. I'ts not surprising at all that a machine built this way would have imprecise movements so what's got my curious is why so many people state the MK2 did not have this problem. What is different in the two machines?

- 24V system

- new control board - specifically the driver chip

- new firmware

- new heatbed - is this one significantly more heavy than the other one due to the spring steel and magnets?

- different extruder traction system.

- are there other significant differences?

I don't have an MK2 and have never seen one in real life

Re: Any response from Prusa on the inconsistent extrusion?

I have a portuguese printer for almost 2 years, and it has a direct drive setup with one gear pushing the filament into the extruder. That gear has sharp theeth and it allways made some kind of inconsistent extrusion along the path of extrusion. With PETG or flexibles I cannot see that inconsistency. With PLA that´s more evident. The bondtech setup has TWO gears with that kind of teeth.

Re: Any response from Prusa on the inconsistent extrusion?

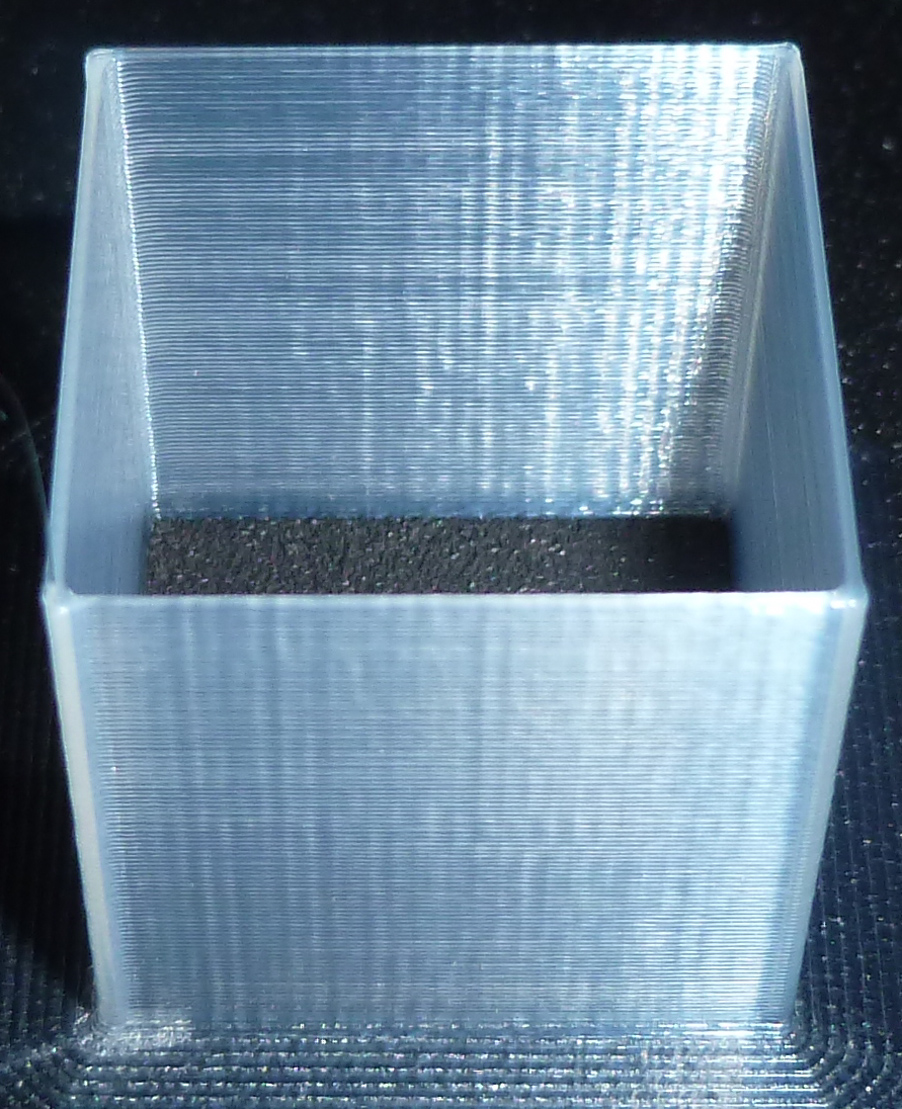

I loaded and calibrated an untinted PLA, and ran the test cube:

There's definitely something going on with vertical stripes, which I think is what you guys are referring to?

I'd be surprised if it was the extruder teeth, only because for them to line up like that layer upon layer seems unlikely to me. Maybe it's ringing? 😕

This was printed at 215C, 0.48mm wide, 0.2mm tall, at a print speed of 2000mm/minute. No linear advance.

Anyhow, I agree that it's not very attractive looking. 🙁

Re: Any response from Prusa on the inconsistent extrusion?

.....

There's definitely something going on with vertical stripes, which I think is what you guys are referring to?

.....

not in my opinion. I think the vertical strips are always there and are either an artifact of the stepper pitch or the belt tooth pitch. I think the affect being discussed is only visible when a good light is shined nearly parallel to the surface. I think basket-weave is the best description of it. Personally I am not convinced it should even be named "inconsistent extrusion" because this describes or assumes a root cause, and this is unhelpful.

Re: Any response from Prusa on the inconsistent extrusion?

From what I've read, the MK2 doesn't exhibit these extruder inconsistencies? if so, wouldn't it be possible to replace the Bondtech with a hotbed gear and idler like the MK2?

Yeah, you'll lose an advertised feature but it will resolve the extrusion issues.

Re: Any response from Prusa on the inconsistent extrusion?

In your guys' opinion, which one of the photos that have been posted on this topic *best* illustrates the problem?

Re: Any response from Prusa on the inconsistent extrusion?

In your guys' opinion, which one of the photos that have been posted on this topic *best* illustrates the problem?

MK3BetaTester's photo on page 4

Re: Any response from Prusa on the inconsistent extrusion?

Is everyone in agreement on that, or does someone wish to dissent and point to a different photo?

My first reaction to that photo is that it looks like over-extrusion resulting from a faulty extrusion width calibration. If I crank up my extrusion multiplier above its correct calibrated value, I get an effect which looks like that.

You need a really good and accurate micrometer and holder to do a proper extrusion width measurement. I only recently received one which does a proper job of it, and before that I saw effects like this, and even worse.

I'm not saying it's necessarily the cause in this case, but.... seems like it's worth checking.

[Edit: I've now looked at my test print pretty hard with harsh light, and I'm just not seeing the effect o display in the designated photo. Sorry. But that's good news, right?

Maybe the particular filament is itself a factor.

Another possible contributor might (?) be the grinding of the gear against the plastic of the idler itself. Martin posted a fix for that, and that's what I'm using. So, maybe that would also explain why I'm not seeing the problem. ]

Re: Any response from Prusa on the inconsistent extrusion?

I have noticed a slight improvement since I started using my fix as well. Also I now use the minimum tension I can get away with.. It gives some very consistant results.

Regards,

Martin

Martin Wolfe

Re: Any response from Prusa on the inconsistent extrusion?

Some progress with a mk3 bowden: https://github.com/prusa3d/Prusa-Firmware/issues/602#issuecomment-403262487

Re: Any response from Prusa on the inconsistent extrusion?

To test the theory, you could tighten the hell out of your extruder idler, so that it gives really deep bite marks to the filament. Do a print that way, then loosen the idler as much as possible and do a print in the loosened state. If the observed effect diminishes, then you will have confirmed the root cause is indeed the idler teeth gnashing into the filament.

I hope that's what it is. There are probably good solutions for such a problem, like maybe using toothless rollers that are simply clamped a little tighter around the filament.

IMO, it's not exactly teeth but resistance.... deeper teeth, tighter gears is more resistance. this has an effect on the stepper torque which is probably detected by the drivers and the drivers make adjustments to motor output, which is why it also affects moire by loosening or changing flow rate (you can change moire direction by flow rate and sometimes they turn into like a squigly/signwave-ish pattern on the surface) .

The move to bondtech lowers the steps per mm, which without an encoder/closed loop isn't the smoothest motion at such low speed.... microsteps help but not every microstep will be taken... current would be too tiny say to move 1/256 or 1/16 so it might move on 4/16 microsteps instead or just lock to 1/2 step. MK2/s has a bit more steps per mm and one gear with less bite so also less resistance so it reduces this issue.

Back in the day, these artifacts were also there... but usually we tweaked extruder gear tension or tuned the motor current via the little pots on the drivers during a print until it was gone/minimized. there is a bunch of solidoodle forum posts and old reprap posts/images with pretty much the same patterns/artifacts.

Anyway, lots of assumptions with nothing backing it up... like the sharp teeth on gears being an issue with air pressure buildup (lol)... well a bowden puts that to rest... go back to the old extruder and gear it up 3:1 or something.....

Re: Any response from Prusa on the inconsistent extrusion?

.....

The move to bondtech lowers the steps per mm, which without an encoder/closed loop isn't the smoothest motion at such low speed.... microsteps help but not every microstep will be taken... current would be too tiny say to move 1/256 or 1/16 so it might move on 4/16 microsteps instead or just lock to 1/2 step. MK2/s has a bit more steps per mm and one gear with less bite so also less resistance so it reduces this issue.

....

Back in the day, these artifacts were also there... but usually we tweaked extruder gear tension or tuned the motor current via the little pots on the drivers during a print until it was gone/minimized. there is a bunch of solidoodle forum posts and old reprap posts/images with pretty much the same patterns/artifacts.

Anyway, lots of assumptions with nothing backing it up... like the sharp teeth on gears being an issue with air pressure buildup (lol)... well a bowden puts that to rest... go back to the old extruder and gear it up 3:1 or something.....

interesting ideas.

I just did M503 on my MK3 and got this output

SENDING:M503

echo:Steps per unit:

echo: M92 X100.00 Y100.00 Z400.00 E280.00

echo:Maximum feedrates (mm/s):

echo: M203 X200.00 Y200.00 Z12.00 E120.00

echo:Maximum Acceleration (mm/s2):

echo: M201 X1000 Y1000 Z200 E5000

echo:Acceleration: S=acceleration, T=retract acceleration

echo: M204 S1000.00 T1250.00

echo:Advanced variables: S=Min feedrate (mm/s), T=Min travel feedrate (mm/s), B=minimum segment time (ms), X=maximum XY jerk (mm/s), Z=maximum Z jerk (mm/s), E=maximum E jerk (mm/s)

..and so on. The steps per unit for the extruder is 280

What is this value for the MK2S? It's difficult to see a giant change here because looking at the Bontech gears they are really small OD and the minor diameter of the groove even smaller. Still it would be interesting to see the comparison.

Re: Any response from Prusa on the inconsistent extrusion?

For those of you who want to try Martin.w15's fix, it is listed as the "BEST ANSWER" to the posted question on this thread: https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/extrusion-gears-grinding-black-petg-idler-part-int-t19247.html

i get the impression most people aren't aware of it, and it is top notch design that, in my opinion, should be a part of the official MK3 build. Like I said, I'm using it, and I'm very happy with it.