Any progress on the extrusion issue (602)?

I try to follow discord and discussions here regarding the MK3 extrusion issue, but it is hard to figure if there is any progress on fixing it.

Does anyone here know if we are getting closer to a fix?

Best regards

Hansen > Greetings from Denmark <

Re: Any progress on the extrusion issue (602)?

No one here knows or no progress... Really? 😐

Best regards

Hansen > Greetings from Denmark <

Re: Any progress on the extrusion issue (602)?

It doesn't seem to have been as big a deal as many originally thought. Yes, if you hold a Prusa print in the right light, you can see minute layer inconsistencies. This is what all the "real" inconsistent extrusion discussions were about. Unfortunately, a lot of people jumped in with other, unrelated issues and the issue got very confused. When folks started actually holding prints made by other printers in the same lighting, it became clear the issue is pervasive. Some printers show it more, some less. Interestingly, when I asked for comparisons made using the same model printed with the same filament in the same light (i.e. stacked together), I got very little response.

To my eye, the sharper the print, the more apparent the inconsistencies are. Prusa went so far as removing the Mk3 extruder and hotend and mounting it on a totally different printer frame and the issue persisted. They also did side-by-side comparisons of the same model printed on other FDM printers with the same filament in the same lighting, and the "issue" was apparent on all of them. There is a blog entry about showing what has been suggested and noting the improvements, but nothing "cleans it up" completely. If it's a real problem, resin printers seem to be the sure fix.

At a few feet, most can't see it. If it bugs you, it bugs you and there's nothing right or wrong about that. Prusa may still be doing some tuning, and if they find a solution, they'll no doubt release it as open source so all the clone manufacturers can benefit as well. Meanwhile, it seems to be the current state of consumer FDM printing. It doesn't seem to be anyone's priority at the moment.

There have been some good comparison threads here. I'm stuck on the road so can't search for the references now, but you should be able to locate them without too much effort if you're really concerned. Just note that the fact that it exists on the Prusa printers doesn't mean it doesn't on others. Do actual side-by-side objective comparisons for yourself.

Edit: It would be interesting to see Prusa repeat those side-by-side tests with Prusament to see if filament tolerance makes a difference!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any progress on the extrusion issue (602)?

@bobstro: Thanks for the detailed reply.

I've been in this "business" for the past 5 years now, and while I have build 6 printers of different topologies, I have never seen any kind of artifacts like the "inconsistent extrusion" of the MK3. Therefore, I don't see this as an inherent part of the FDM technology. Also, from Discord it seems like the issue disappears when replacing the extruder. So: Yes, it bothers me 🙂

Best regards

Hansen > Greetings from Denmark <

Re: Any progress on the extrusion issue (602)?

If you've got other printers, I'd really appreciate it if you would print a 20mm cube on each in the same filament and stack them (not side-by-side) and go for the worst-case lighting. All of the "comparisons" I've seen have each cube held at slightly different angles, and with this issue, slight angles make a big difference. Part of the confusion comes from the fact that some have claimed that Prusa printers prior to the Mk3 didn't have the issue. Bytor did us a nice comparison in this thread, with interesting results. It'd be great to see such a comparison done by someone besides Prusa for comparison.

I've been in this "business" for the past 5 years now, and while I have build 6 printers of different topologies, I have never seen any kind of artifacts like the "inconsistent extrusion" of the MK3.

Obviously, if it bugs you, the Prusa FDM printers may not be the way to go. For myself, if that sort of thing bugs me, I'm going to be looking for something besides FDM to start with.

Thanks!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any progress on the extrusion issue (602)?

It is a hardware “issue”. The pressure in the hotend is not constant. When you have a bowden setup there is “room” for the pressure to go back. The bondtech gears don’t allow for that. The older Prusa printers have gear systems that allow for more pressure release.

So it is a FDM problem but it is more visible on extruders which have “more gripping power”.

Re: Any progress on the extrusion issue (602)?

Ah, interesting. The last time I'd checked, the problem had apparently been narrowed down to "something to do with the bondtech extruder". I quit following the github thread once it got over-run with false positives. It's good to hear there is still some work being done on the core issue.

[...] So it is a FDM problem but it is more visible on extruders which have “more gripping power”.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any progress on the extrusion issue (602)?

When folks started actually holding prints made by other printers in the same lighting, it became clear the issue is pervasive. Some printers show it more, some less. Interestingly, when I asked for comparisons made using the same model printed with the same filament in the same light (i.e. stacked together), I got very little response.

Very real basket-weave and moire patterns were present and ARE more or less visible depending on color used, lighting and filament type. SOME of these issues are present in every printer but spend 5 seconds on the git and you'll see plenty of prints that are unacceptable on a 1000$+ machine.

The controversy came with the responses from prusa and other fanboys to the effect of "you are wrong, you assembled it wrong, prusa printer is best printer josef is always right and your results are invalid". At the end of the day there are plenty of us on the 602 discord that just want to improve our prints and could care less about the controversy

Best summary of the issue and various fixes so far:

Re: Any progress on the extrusion issue (602)?

That video's a good example of why I'm still looking for good examples of prints done under identical conditions. He uses different filament (OK, fair enough. That shouldn't make much difference for this issue.) but also totally different layer heights (0.15 vs 0.28mm). I'd really like to see good examples of the same model printed using the same settings with the same filament under the same lighting conditions. I've read through the github pages and seen a couple of cubes held in someone's hand at slightly different angles. I've been a bazillion pics of the issue showing only a print off a Prusa. I can clearly see the issue myself, and I'm not arguing that it doesn't exist. I'm just asking the questions "as compared to what?" The only real side-by-side comparison I've seen was Bytor's that I linked to above. Despite claims that older Prusa printers didn't have the issue, his seemed to.

[...] Best summary of the issue and various fixes so far:

I'm hardly fanboying. I'm really curious to hear if as many other printers as I've heard about are free of the issue. I almost pulled the trigger on an Ender 3 out of curiosity.

Again, I see it. I can understand why it might bother some people. For my purposes, it's not a problem. I spend a lot of time on Reddit and see a lot of prints posted that were printed with other FDM printers, and the Prusas consistently look pretty good in comparison. I'm trying to decide if going with another mainstream printer would eliminate the issue, or simply trade it for a host of others.

Are you aware of any galleries showing objective side-by-side (or better, stacked) comparisons? What I'd really like to get my hands on is a simple model printed with an "ideal" printer that is considered to be free of defects just so I have something to shoot for.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any progress on the extrusion issue (602)?

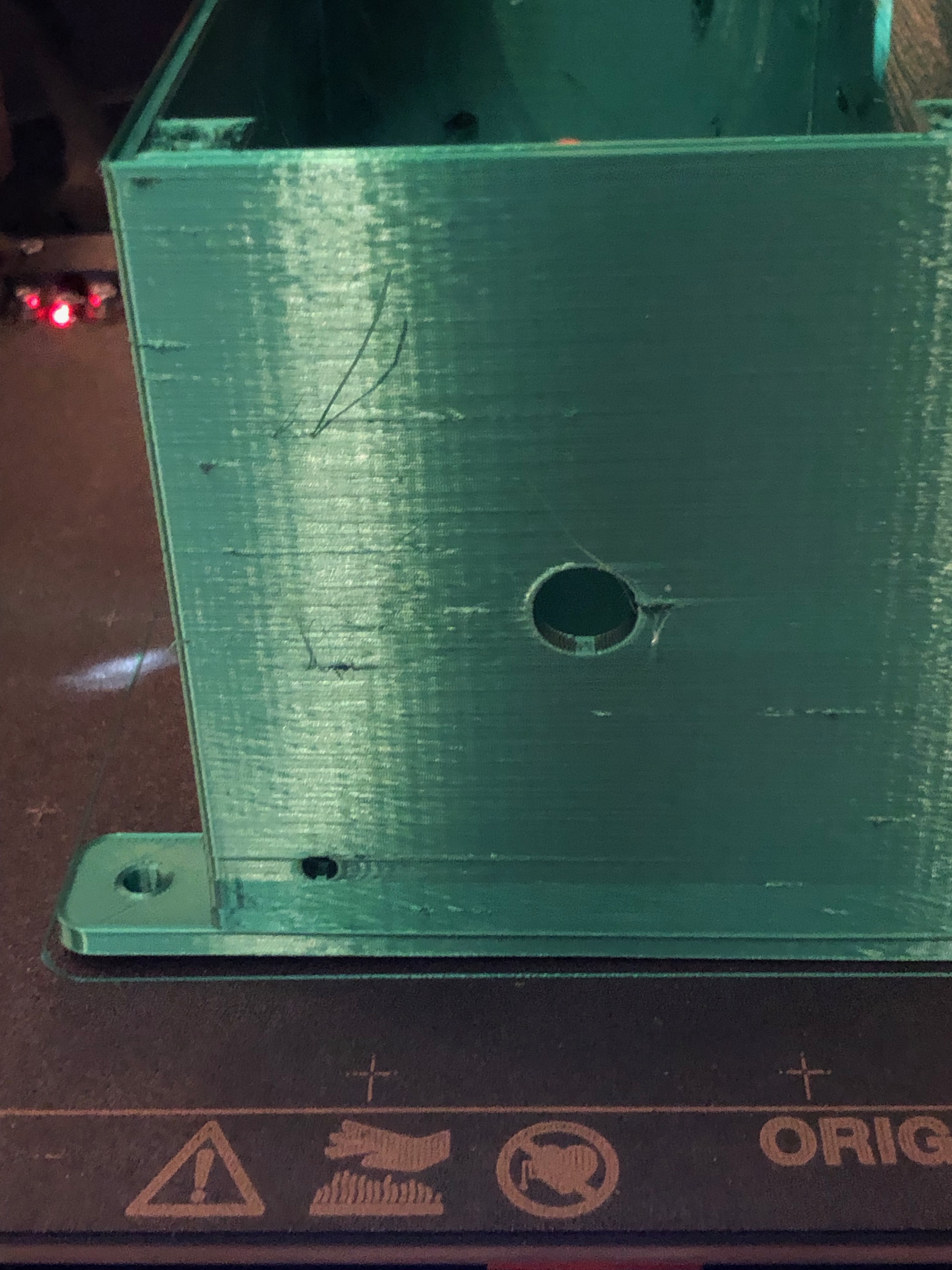

I was fiddling with print scrap While on a long support chat with Shane last night (MY pinda has aged badly they are sending me a replacement) i was unfolding some support material and its walls are (8.6mm high in this unfolded strip) just about perfect

not that I am complaining, the actual walls on my large prints are fine for their mechanical usage but the difference is quite large. these are the same PLA at the same settings

Re: Any progress on the extrusion issue (602)?

That's a vertical surface compared to a horizontal surface. The horizontal could be cleaned up, or use something like Cura's ironing feature.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any progress on the extrusion issue (602)?

[/quote]

That video's a good example of why I'm still looking for good examples of prints done under identical conditions. He uses different filament (OK, fair enough. That shouldn't make much difference for this issue.) but also totally different layer heights (0.15 vs 0.28mm).

[...] Best summary of the issue and various fixes so far:

I guess the video is assuming that you already have the issue and are interested in the fix. For every comparison photo on the git there's another on warcocki's fb group showing the exact opposite. Remember this issue is......"inconsistent". I have a 150$ mp mini which will stack layers like the "steve mk1" all day long.

Again, I see it...For my purposes, it's not a problem.

Its 100% a visual issue and if you're not printing in shiny pla all day long then you probably won't notice it and/or its not as apparent on your machine for whatever reason and that's awesome and more power to you.

two more updates including one forum member going to prusa hq and doing quite a bit of work...

SO...after all was said and done we are left with a lot of optional improvements/mods to the printer and assembly methods which have shown clear benefits in different areas, if not a complete solution to the original issue. We've already seen some of these changes implemented in the R3 design.

Re: Any progress on the extrusion issue (602)?

[...]

two more updates including one forum member going to prusa hq and doing quite a bit of work...

SO...after all was said and done we are left with a lot of optional improvements/mods to the printer and assembly methods which have shown clear benefits in different areas, if not a complete solution to the original issue. We've already seen some of these changes implemented in the R3 design.

Thanks for the links. I hadn't see CRT's follow-up video. I think he answered the OP's question (paraphrasing):

"Quite frankly, I am a bit bored of it. And the issue was not that major to begin with. It was fairly obvious, especially once you noticed it, but in the grand scheme of things, not that big a deal. And their does seem to have been some firmware changes that affected the amount of 602 that we see."

In short: There have been firmware tweaks that incrementally improve quality. There are recommendations for tuning that may help incrementally with some issues. The issue is visible. If it bothers you, you might want to look into a technology other than FDM, or another FDM printer. If it doesn't bother you, the Mk3 is an excellent printer.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Any progress on the extrusion issue (602)?

In short: There have been firmware tweaks that incrementally improve quality. There are recommendations for tuning that may help incrementally with some issues. The issue is visible. If it bothers you, you might want to look into a technology other than FDM, or another FDM printer. If it doesn't bother you, the Mk3 is an excellent printer.

qfe.

I'll reiterate that a lot of good did come out of it eventually, and his videos are a good starting point for anyone interested in incremental upgrades.

-improved z mounts

-R3 extruder and/or many other extruder options (vekoj, skelestruder, etc)

-improved x ends/clamps

to name a few. reversing the bondtech idler completely fixed the moire issue, but I don't think he tested that (just the 608 bearing idler)