A Tale of Two Sheets (Discussion Thread)

This is the comment/discussion thread for an upcoming thread I am posting on PC sheets and bed adhesion. That is going to be a multi-post dive, and will likely have quite a few lengthy/detailed posts by me. Given the nature of it and the way I'd like to present it, I am opting to create a separate comment thread for it so that primary content I intend to post there stays relatively uninterrupted and on-topic. Alas the system here has no way for me to "reserve" a few posts at the beginning and edit them later to insert additional content before the discussion.

Thanks for your understanding, and stay tuned! I'll be monitoring this thread as I post things, so yes, I should see any comments you leave in regards to whatever the latest addition there is.)

Obviously, there's nothing to see here yet, but I am drafting post #1 now and expect to post shortly. (I just needed this thread to exist first so I could link to it).

RE: A Tale of Two Sheets (Discussion Thread)

Will be interested to see the results. Any way to measure lateral force emulating the nozzle passing over the part?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: A Tale of Two Sheets (Discussion Thread)

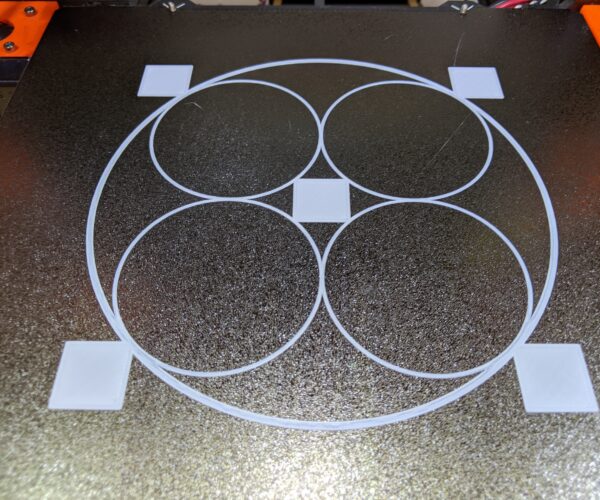

I can definitely take measurements at an angle as well. I suspect a 90 degree is not unreasonable since it is essentially a shear force parallel to the plane of attachment. I expect the measurements would be proportional to the vertical ones, at least for uniform shapes. Where that starts getting complicated is when you have irregular forms so that the force is not uniformly distributed across the surface. Might be interesting to take a look at outline vs strength to quantify that, e.g. "how much weaker is a square compared to a circle of the same area")

I do have some preliminary numbers for testing that do show a difference between our sheets but I did not write them up as I need to redo the test. Your sheet seemed to average around 600g of force to remove a part, my sheet maxed out my gauge on the first part (2000g!!) and so I dropped the temp to 50c and ended up getting numbers similar to yours. But I don't want to read into that too much as they were also quite variable, suggesting my sheet might need another dunk. I also need to gather some numbers from my smooth sheet for comparison. Once I have those I can start doing that part of the write-up.

RE: A Tale of Two Sheets (Discussion Thread)

Glad you're able to test in depth. Will also be curious to know if there's a measurable difference between the uneven side and the other.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: A Tale of Two Sheets (Discussion Thread)

Will be interested to see the results. Any way to measure lateral force emulating the nozzle passing over the part?

Presumably you’re talking about the force imposed by the material flowing from that nozzle? That would be an interesting set of equations in that it seems all kinds of things would come into play: CoF, viscosity, viscosity cooling delta, angle of “impact” incidence upon first arrival, etc.

gotta love this stuff!

Every man I meet is in some way my superior. --Ralph Waldo Emerson

RE: A Tale of Two Sheets (Discussion Thread)

Science! (amirite?)

Hopefully I have some time after work today to do the writeup for the second sheet.

RE: A Tale of Two Sheets (Discussion Thread)

It will be interesting to compare my brand new, never been out of the wrapper with your images. Waiting on USB microscope delivery.

Awesome job!

Is it possible for you to post 3MF file for your test pieces?

Quality is the Journey, not the Destination. My limited prints->

RE: A Tale of Two Sheets (Discussion Thread)

@vintagepc

Really interesting thread Vintage. Can I say I like your sense of humour too, just whats needed in the morning 🙂

I think those patterns on yours are the same sort of thing you get when a window ices over, the crystalline structure of the pei 'setting'.

RE: A Tale of Two Sheets (Discussion Thread)

@vintagepc

Really interesting thread Vintage. Can I say I like your sense of humour too, just whats needed in the morning 🙂

I think those patterns on yours are the same sort of thing you get when a window ices over, the crystalline structure of the pei 'setting'.

I think so as well, but I don't want to jump to a conclusion based on just two data points. But in theory it's certainly possible that adhesion differences arise between crystalline PEI vs amorphous PEI. Not sure how one would go about testing that.... yet.

@kennd: Sure, I do intend to post an STL/3MF, but I'm having some measurement consistency issues I need to work out first which I suspect may be partially caused by the shape - I'd like to get that sorted first.

RE: A Tale of Two Sheets (Discussion Thread)

I gathered some numbers over the weekend. Stay tuned for the write-up 🙂

Setting expectations

It's probably a good idea to set expectations on what a "good" result looks like. For me, I'm looking for results as good as, if not better than, what I get from the smooth PEI surface. This is based on how Prusa advertised the textured sheet. I am expecting good adhesion without the need for sprays or gluestick.

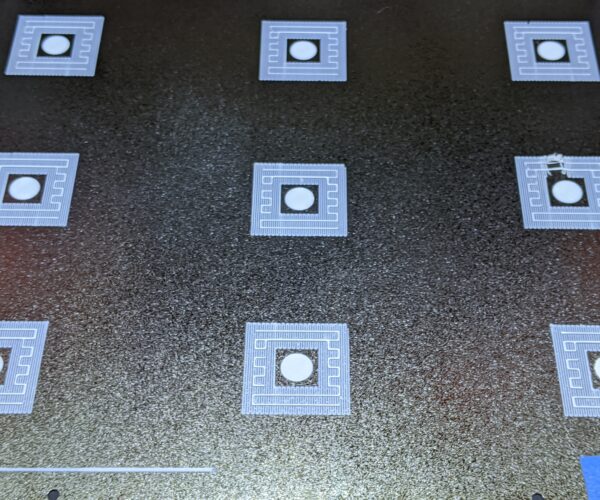

Here's a good result on my textured TheKKIINNGG sheet. Not perfect -- that bit lifted at the center-right, but the print would succeed reliably. I had given the sheet a Dunk with Dawn shortly before, but may have touched that part inadvertently. The white samples are Inland PLA printed with a 0.40mm nozzle. A simple Dawn wash with no alcohol or other prep.

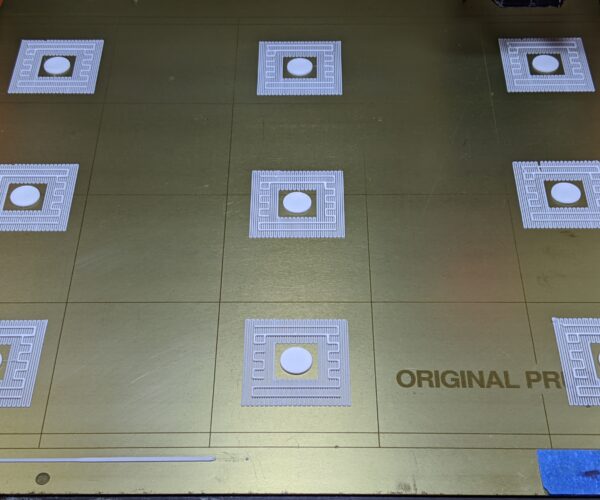

Here's the same on the Prusa smooth PEI sheet. Again, not perfect, but sufficient to knock small parts out all day without worry.

I'm also not expecting to need brims or other crutches to get small part adhesion, even on complicated prints with lots of movement.

1st layer supports should be reliable.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: A Tale of Two Sheets (Discussion Thread)

Agreed. Numbers alone don't tell the whole picture but will give us something quantifiable. once that aspect is hashed out we can take things from theory to practice. I don't want to spoil the surprise, (hope to write the post tonight) but the results were... somewhat unexpected. 🙂

RE: A Tale of Two Sheets (Discussion Thread)

Agreed. Numbers alone don't tell the whole picture but will give us something quantifiable. once that aspect is hashed out we can take things from theory to practice. I don't want to spoil the surprise, (hope to write the post tonight) but the results were... somewhat unexpected. 🙂

Looking forward to it. I'm keenly interested in the numbers, or to figure out why some of these sheets are turds and others magnificent. Of course, no way of knowing what accounted for the PEI crazing since I did resort to an acetone wipe and washes to try to get mine going. If I understood your previous microscope pics, there are gaps between some of the PEI textured bits that have exposed bare metal? Is that the case on your "good" sheet as well? Hoping Prusa didn't just cheap out on the coating.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: A Tale of Two Sheets (Discussion Thread)

The bottom of the "pits" that create the texture are just bare sheet, yes - even on the virgin side of my own sheet. That's why PR advises against washing the sheet with water as that's what's going to start rusting.

RE: A Tale of Two Sheets (Discussion Thread)

The bottom of the "pits" that create the texture are just bare sheet, yes - even on the virgin side of my own sheet. That's why PR advises against washing the sheet with water as that's what's going to start rusting.

Yowza. I wonder if the original Prusa textured sheets were the same. That really makes me question just how rugged they are. I'd expect leaving gaps like that to make it easier for bits to pull up.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: A Tale of Two Sheets (Discussion Thread)

@bobstro

Well, as long as the adhesion is uniform and the surface smooth and continuous, it should be fine. Not as good as it could be, but a lot less of an issue than if you have sharp corners or cracks for lifting to start (much like warping on square corners during a print).

But yes, the sheets would likely be a lot hardier if there was a thin film of PEI over the base metal, on top of which the texture coat was applied.

I too would be interested in finding out what an original PC sheet looks like up close - esp. from before PR moved the production in-house.

RE: A Tale of Two Sheets (Discussion Thread)

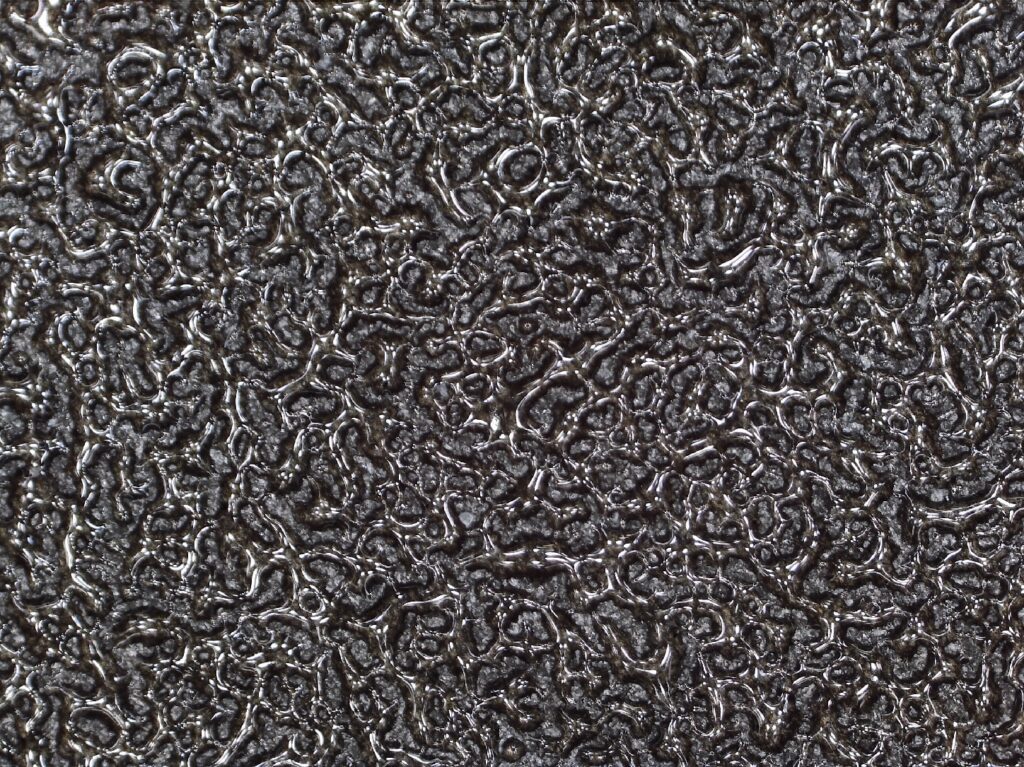

This is a sheet from October 2018, notice how much bare metal is exposed.

One thing I have never seen is anyone with as an agressive texture as the PRUSA printed parts, theirs are almost like as if the sheet was covered in sand first, then the PEI melted over it, whereas we have a much less rough surface on out prints.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: A Tale of Two Sheets (Discussion Thread)

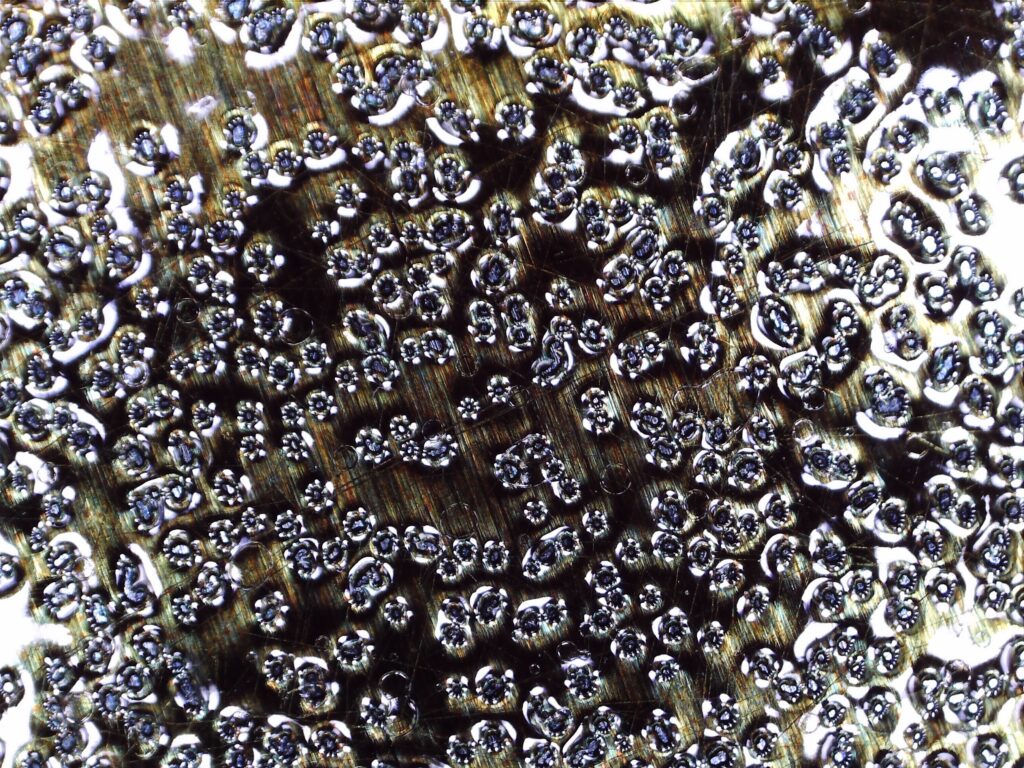

I know I've posted these before, but here is a brand new one from last summer:

And for comparisson a brand new (last week) Thekkinng V4:

Neither of these have ever been printed on yet.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: A Tale of Two Sheets (Discussion Thread)

The original sheet I use for PETG only, it has only ever seen IPA and one soap wash in it's life, I print with a bed temperature of 85 first layer and 90 for the rest, the PETG sticks to it really well and I have to let it cool, once it dips below 70 Deg, the print may pop off.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: A Tale of Two Sheets (Discussion Thread)

Interesting, though it's hard to tell at that zoom level whether the bottom of the textured pits on the original sheet are bare steel or have a thin film on them. Could be either guessing by the way the light plays around.