Z axis can't go up all the way (With video)

I'm super excited that I finally go the MK3 kit and built it 😀 . I did the setup wizard and everything seemed to work fine (with the exception of the filament not extruding for some reason at first, then it started to work). During the wizard it did the XYZ calibration, and the Z axis went all the way to the top and back down to the bed and did its thing for a while in the 4 corners. I did the first layer calibration and got it set OK, not perfect, and then printed the Prusa logo which came ok pretty good, first layer was horrible but, didn't seem to affect it.

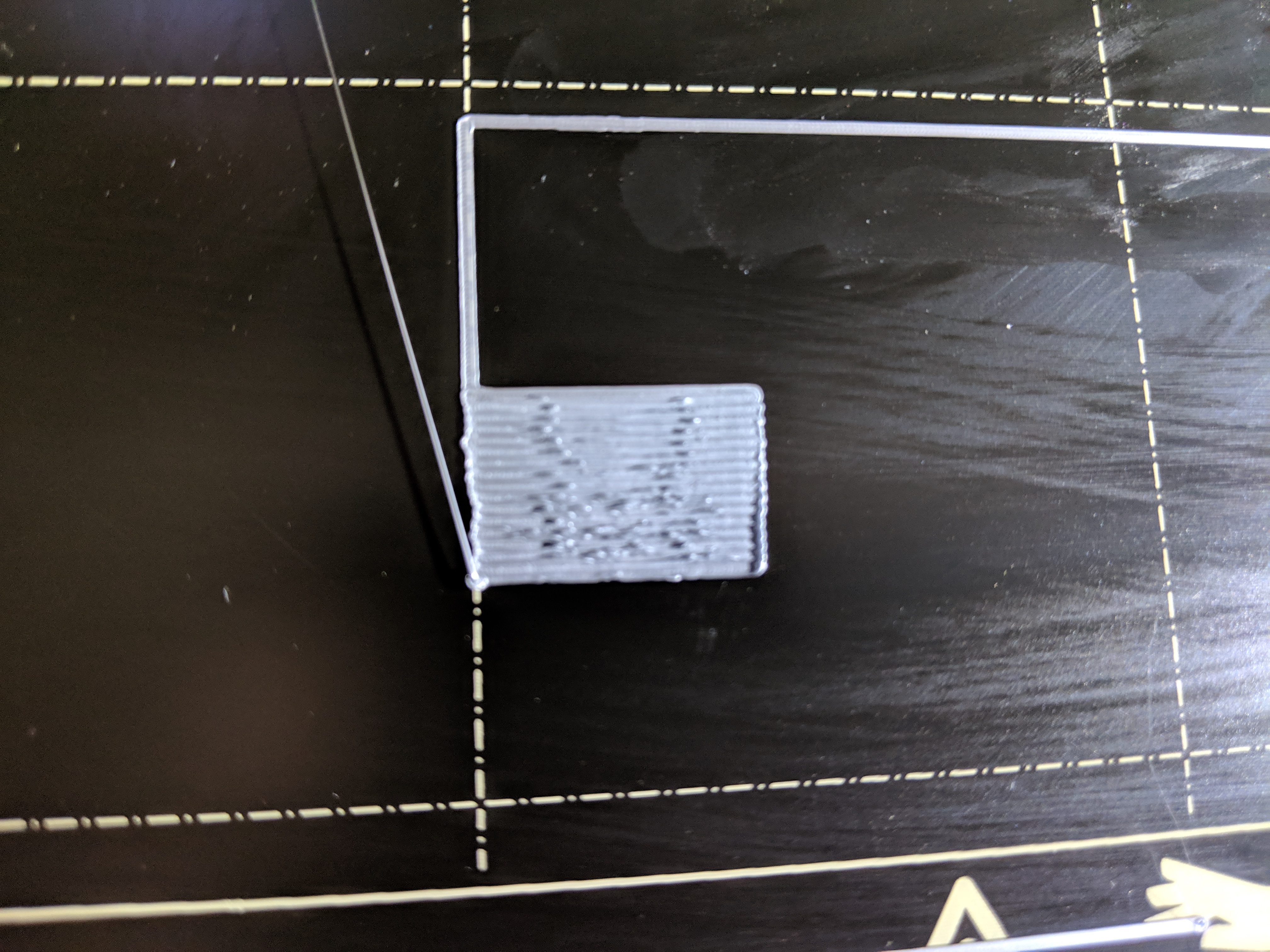

I can't really tell what to do the make the first layer calibration better, to far or to close? -0.7 seems to be to close maybe? -0.6 seems ok but it doesn't seem to want to stick..

-0.700 (Below)

-0.600 (Below)

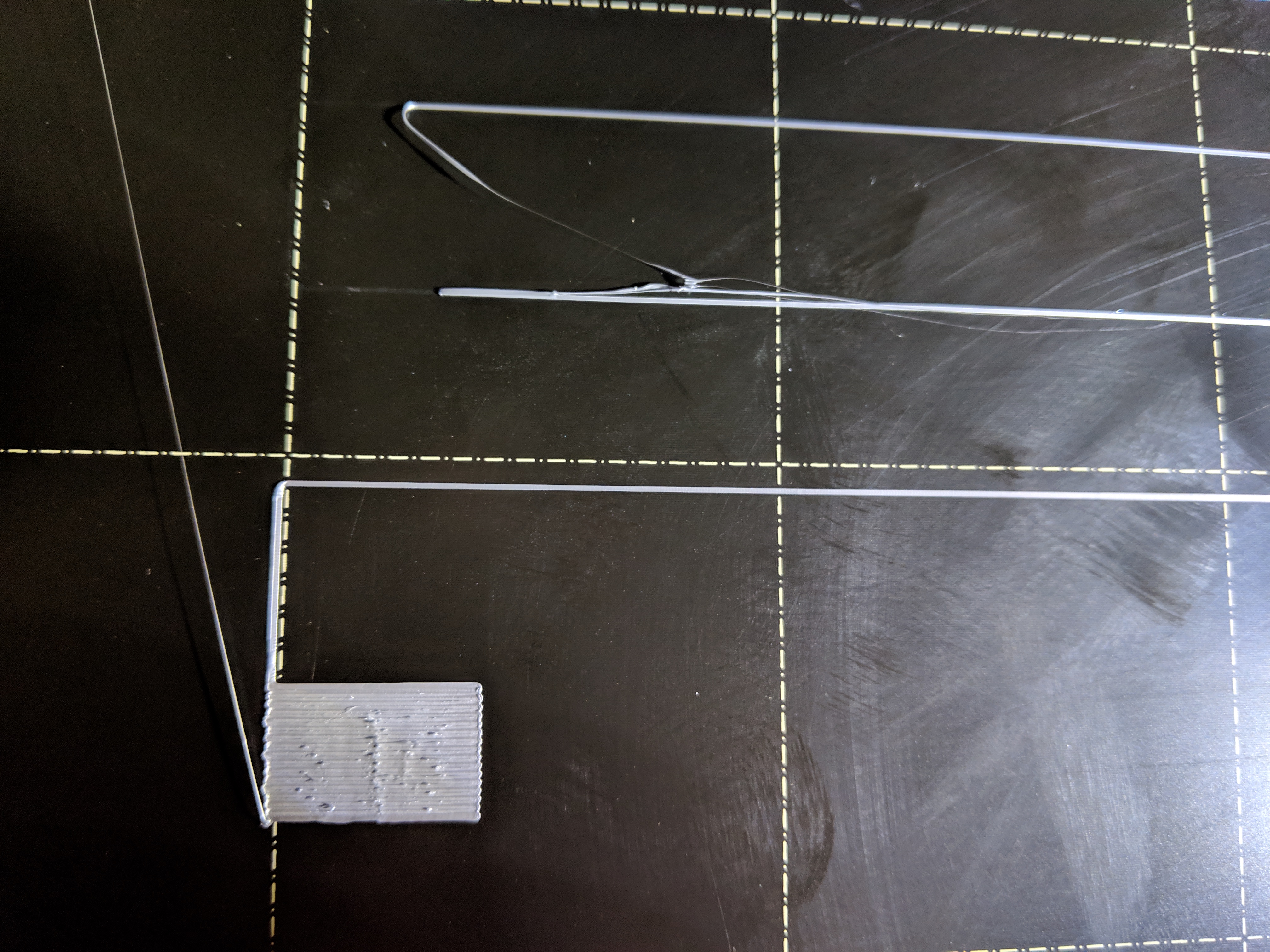

So far that is the only thing I've been able to print, and after trying to print a basic model that is basically 2 rectangles and failing about 5 times, I thought maybe I should re calibrate that first layer, so after playing around with it, I think I may have gotten it to a better level. Below is the failed rectangles. Also another interesting thing to point out on these failures is it failed twice on just laying down the skirt, before getting to the actual print, then failed 3 other times always on the second rectangle.

Then I proceeded to try and calibrate XYZ again, and noticed when it would raise the Z axis, it would just stop half way and ask me to clean the nozzle, then lower to the bed and say it failed. I was confused, and then tried to manually move the Z axis all the way manually, and sure enough, the left side seemed to seize up at about the halfway mark.

Link to the video of the Z axis raising: https://photos.app.goo.gl/73m9y1duyQnYgnebA

Any advise on the first layer issue and ideas on the Z axis issue?

Thank you 🙂

Re: Z axis can't go up all the way (With video)

From the video the first observation is the X axis upper bearings have been pushed in too far, one end should be up against the stop in the printed part the other pushed up until just flush with the end

It also looks like the x axis rods have not been pushed far enough into the printed part so the overall x axis length between the centres is longer than the frame and z axis can accommodate

'Printed part' in both cases being X-end-motor and X-end-idler

if the z axis cannot hit the stops at the top of the travel it can't calibrate

https://manual.prusa3d.com/Guide/3.+X-axis+assembly/508?lang=en

Re: Z axis can't go up all the way (With video)

you could be a little bit to far off the build plate but aso from the photo the build plate looks a bit unclean. if it is that will not help with the filament sticking.

Start off with a hot water and detergent. Then an alcohol wipe or window cleaner, which ever one you use. Also try the other side of the build plate, the have been issues with some plates and print not sticking. My PEI sheet plate is better on one side than the other.

Re: Z axis can't go up all the way (With video)

you could be a little bit to far off the build plate but aso from the photo the build plate looks a bit unclean. if it is that will not help with the filament sticking.

Start off with a hot water and detergent. Then an alcohol wipe or window cleaner, which ever one you use. Also try the other side of the build plate, the have been issues with some plates and print not sticking. My PEI sheet plate is better on one side than the other.

Yeah I noticed it looked dirty also in the picture, I had been cleaning it with 91% alcohol, but after having so many bad first layer cals I tried the included glue stick, which didn't help, that might be from those pictures (can't remember). I will also try the detergent bath, thanks 🙂

From the video the first observation is the X axis upper bearings have been pushed in too far, one end should be up against the stop in the printed part the other pushed up until just flush with the end

It also looks like the x axis rods have not been pushed far enough into the printed part so the overall x axis length between the centres is longer than the frame and z axis can accommodate

'Printed part' in both cases being X-end-motor and X-end-idler

if the z axis cannot hit the stops at the top of the travel it can't calibrate

https://manual.prusa3d.com/Guide/3.+X-axis+assembly/508?lang=en

Wow! thank you for the pictures! I did push the bearings all the way to the bottom stop on both the printed parts. I do know for a fact I got the rods pushed in all the way because it took me a good half hour to muster up the strength to push them in till I saw them in that little window lol. I must not have been able to tell from the pictures when I was originally building this step that they weren't both pushed all the way in, just oriented a certain way.

Thank you both, really appreciate the feedback, I will give what you have told me a try and hope this fixes my issues ^.^!

Re: Z axis can't go up all the way (With video)

So I fixed the issue of the one side not going up after a certain point... I don't know how I missed this but I had installed a rPi case on that side lol 😳 , overhang just enough to hit the X motor... >.<

So with that issue out of the way and now seeing how much of a big deal it would be to take apart the X axis completely and fix the bearings, on a scale of 1 to 10, how bad is it that they are together? 1 being no problem at all, and 10 being, I need to fix it immediately lol.