Wobbly / uneven vertical edges and walls with PETG

Hi everyone,

this is actually not a first print, but I recently started to print a lot with PETG, where this issue is significant with my setup. But as it occurs even for very simple geometries, it is not related to sophisticated or hard to print structures.

When printing objects with straight vertical edges, this results in reproducible (as in: always on the same height for a given geometry) "dents" on that line, that seem to squish out a little bit. However, they recover after a few layers.

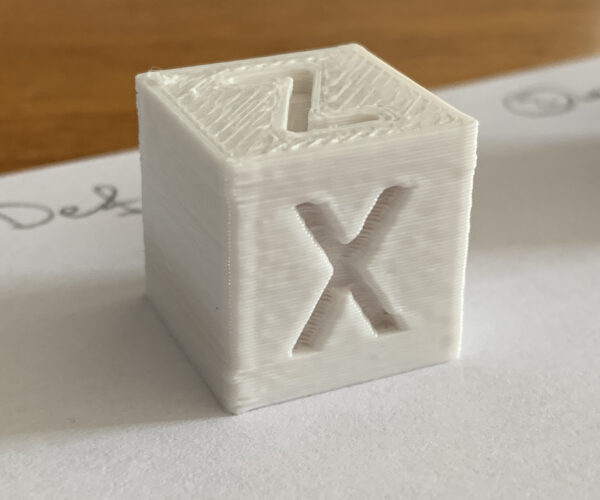

One simple example is the XYZ calibration cube:

I printed this with a 0.6 mm nozzle, so don't mind the rough surface, it's a pretty small geometry for this nozzle.

As I see it, this is neither ghosting nor layer shifting, but something different. The effect doesn't change by reducing extrusion multiplier (0.97 instead of 1), lower speed (about 50% instead of 100%) or higher nozzle temperature (260°C instead of 250°C, this is Prusament PETG).

I'm printing in an enclosed chamber which is actively temperature controlled (here to 35°C).

Any tips for reducing this?

Addendum: This is a MK3S+ and my belt tension seems OK (feels good, pulley screws are tight, belt status is showing 259 and 279 for X and Y).

More findings

Meanwhile I tested some more parameters. Lower nozzle temperature shell thickness (3 lines instead of 2) do not help. Lowering or turning of fan (default filament profile is at autocooling with 50% as base) results in a very bad print quality, turning up the fan up to 100% does not help and shows no significant difference from the default settings.

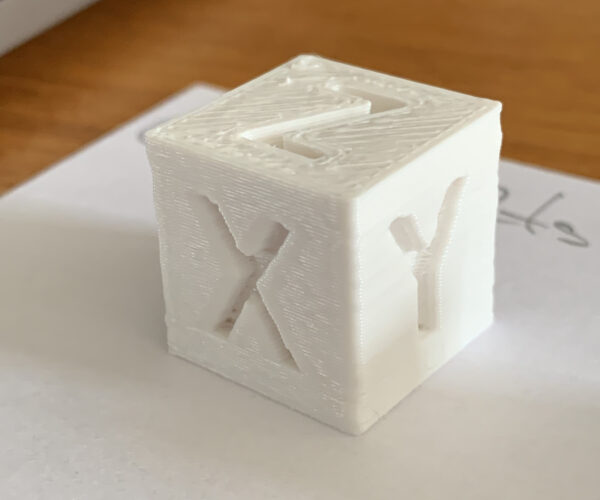

However, a high infill value does help. The following picture shows a cube with 60% infill instead of 15%. While still not perfect, the result is a lot better.

Bearing drag?

One thing to think about is whether your X and Y bearings are over tightened (causing drag) or under lubricated. The infill change is the good old "buldge" issue - keep your infill values up to prevent external perimeter from showing weird ghosting-like variations. However, the wobble in your walls is something I've seen before and usually relates to bearing drag. X is most common - too easy to over-tighten the extruder carriage back plate, but Y bearing holders - especially those old U bolt style, can also be over-tightened leading to this type of variable perimeter wobble.