Why does Prusa not recommend lubricating the bearings for MKS3+?

Now that my printer is fully assembled and working great, I am reading up on maintenance. One of the issues is of course bearing lubrication.

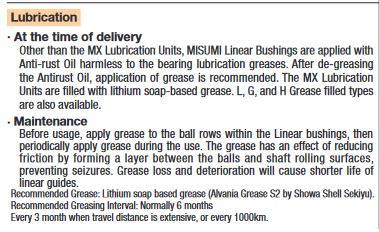

In the MKS3+ manual it specifically says that the bearings are lubricated, and do not need to be lubricated prior to assembly. However, from what I read, the Misumi berings only come soaked in anti-corrosion oil, and really should have been lubricated with lithium/PTFE grease. The MINI assembly guide describes this procedure. Why hasn't Prusa taken the time to correct the online and up-to-date MKS3+ assembly guide? I didn't even think to question this while building, this being my first 3D printer.

I do not particularly feel like disassembling a significant portion of the printer to get to the bearings and properly grease them, but being somewhat paranoid about maintenance and correct assembly, this is really irritating...

It will surely work fine for a good while, but the maintenance guide only says to apply grease on the metal rods, which will not really get into the bearings due to their seals. I will probably partially disassemble, clean out the anti-corrosion oil, and grease the bearings properly at that time.

Why does Prusa not recommend lubricating the bearings for MKS3+?

Probably because they've never needed it. Prusa's print farm runs hundreds of machines 24/7 with regular maintenance. If there were genuine issues they would see them first.

My bearings have run fine for five years with just a touch of lubricant on the smooth rods every month, no grease-packing.

Cheerio,

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

The ‘pack bearings with grease ..or not’ question it’s a bit like the ‘silicon sock ..or not.’. People opinions and mileage varies a lot. You have run your printer for years without issues, while other users had problems with dry bearings grinding and scratching the rods, only after a few months of use. I experienced this problem with the two upper bearings of the X-axis. I had zero issues with the Y or Z bearings. Of course, my printer was assembled without applying grease because the manual said it wasn’t necessary and, back then, I knew nothing about this question.

Misumi sells factory sealed bearings which aren’t packed with grease, only protective oil. AFAIK they sell also bearings already prelubed inside. I’ve purchased twice LMU8 Misumi bearings, not from Prusa but from another vendor. They weren’t packed inside.

We don’t know what they do with the printers at their farm. Do they use not-packed bearings as they come frem Misumi ?. Do they pack them with grease?.Do they get already prelubed bearings ?. Your guess is as good as mine.

I think that Prusa should clarify definitively this matter, just to end the arguments and uncertainties.

RE:

Original Misumi bearings are available in 2 variants:

- prelubricated

- with anti-corrosion oil only

I always recommend using a suitable lubricant, such as an NLGI 2 grease or at least a suitable oil, when moving steel on steel.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

Thank you for everyone's replies.

I was exceptionally happy with the kit quality, as well as the instructions, except for this section. I really wish Prusa had modified the MKS3+ instructions to match the MINI instructions to use proper grease instead of just leaving the anti-rust oil on. They do include the printed part that's made specifically for the purpose of packing the bearings with grease. If I had done so during the build, the extra work would have been minimal. Getting it done now is hours of disassembly work, risking de-aligning the perfectly parallel axis I have now. So, I will postpone until it's time for a thorough maintenance.

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

Upon reading through the comments section in the instructions, I found this quote, so that is re-assuring, even though I wish I had used the proper grease:

"The bearing's treatment is sufficient lubrication for the first use period. Some lube never hurt, but we have found little benefit in doing this "fix by IPA and lube" on brand new bearings before installing, and you will still have to maintain your printer and lubricate later. As we honor the warranty on the hardware installed correctly for years, we would be the first to tell you if it was really necessary.

William H. - Official Prusa"

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

Just stop guessing. Whatever you read about Misumi delivering into commerce, how do you know what Misumi is delivering to Prusa. If you don´t trust Prusa´s instructions despite the official manuals, you are still free to do as you please.

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

"The bearing's treatment is sufficient lubrication for the first use period....

...so I would save myself further maintenance work and lubricate the bearings properly before the first start-up. Lubricating the guide shafts with grease afterwards is rather suboptimal.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE:

Just stop guessing. Whatever you read about Misumi delivering into commerce, how do you know what Misumi is delivering to Prusa. If you don´t trust Prusa´s instructions despite the official manuals, you are still free to do as you please.

No need to guess. I built my Prusa from a kit back in March, and then I built a second printer (Bear upgraded Prusa) from scratch a month or two later. Sourced all of the components myself including a handful of things from Prusa. My Misumi bearings for the second printer did NOT come from Prusa, and yet they were delivered in identical packaging as the ones in the Prusa kit, with the same light anti-corrosion oil.

The bearings do not come pre-lubricated from Prusa; they merely come with an oil and in packaging that is intended to prevent them from corroding before they are installed, per Misumi. I suspect the reason Prusa still persists in saying the bearings come pre-lubricated at this point is due to a stubborn unwillingness to admit they didn't fully understand the proper use of a component that is a critical part of their product.

As far as the entire cleaning regimen with IPA (recommended by some) prior to greasing the bearings, I happen to think that's a waste of time. Just use the included nozzle and grease to pack the bearings prior to installation and be done with it. Don't go crazy with it, just until the grease starts to squeeze out a little on the ends. I used the tube and nozzle that came in the Prusa kit to lube the bearings on the first printer, and the X/Y bearings on the second, and still have some left in that tiny tube. I used 10mm bearings and rods on the Z axis so that took a different nozzle that fit a tube of Super Lube I already had.

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

The one thing I have not been able to hear directly from the horse's mouth at Prusa is what, exactly, is the lubricant that comes in the bearings when they are shipped?

Is it the so-called shipping-only lube, as cited by some, or is it something else.

Having said that, my Prusa I3 printer has surpassed 20,000 hours of printing time. There's no evidence of the bearings being inadequate, such as noise, play, or scoring of the rods.

My periodic procedure is to put a drop or two of lightweight synthetic machine oil on the rods every so often, and rub some Superlube on the rods every so many so-oftens.

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

Having been down this at great length, I'm convinced there is 0.0001% chance that Prusa is getting the bearings with lube as Misumi doesn't sell them that way to any general public. I talked directly to Prusa support who says "we *don't not" recommend against lubricating them." Support also did not say they got 'special lubed bearings'. The packing oil is light, but it is a lubricant. Add lube on a regular basis and I'm sure that the bearings will last a long time. Like all manufacturers, Misumi makes recommendations to get the most life out of its bearings with the least maintenance on the user's part. And while they sell lubed bearings.. these ain't them. I think Prusa is simply going on its Print Farm statistics which obviously have a maintenance schedule that includes lubing the rods on a regular basis; and just by trial, the bearings hold up for years (so I'm assuming).. or Prusa would be changing their recommendation. It is not unusual that manufacturers are over cautious when it comes to user maintenance.

However, something that can 100% do no harm is to clean the bearings and lubricate them according to mitsumi's recommendation. When I bought a spare bearing from the place I get my Prusa parts.. there is a warning right on the website for the bearing.. "clean and lubricate this bearing". Can't hurt. But if installed, I wouldn't worry about it.. just lube the rods every 200 hr.

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

Followed Prusa assembly instructions and did not lube the bearings on assembly. Been running two years (many prints a week) now without any issues.

I do apply a smear of grease from the Prusa tube on the rods when they feel dry and I got some Super Lube synthetic oil and silicone lubricating grease if that ever becomes necessary.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

Lubing the rods periodically is probably a good compromise for maintaining an already assembled printer that is in service. The seals at the ends of the bearings seem to do little to retain the grease in the bearings, so I doubt if they do much to keep it from getting to the bearings either when it is applied to the rods. A small lube hole or needle fitting would be nice, but then most people would overlube them.

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

Same here.

I have also built 6 Prusas and I did lube the bearings during assembly.

The one thing I have not been able to hear directly from the horse's mouth at Prusa is what, exactly, is the lubricant that comes in the bearings when they are shipped?

Is it the so-called shipping-only lube, as cited by some, or is it something else.

Having said that, my Prusa I3 printer has surpassed 20,000 hours of printing time. There's no evidence of the bearings being inadequate, such as noise, play, or scoring of the rods.

My periodic procedure is to put a drop or two of lightweight synthetic machine oil on the rods every so often, and rub some Superlube on the rods every so many so-oftens.

--------------------

Chuck H

3D Printer Review Blog

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

My bottom line conclusion is that Prusa has determined that whatever lube is on the bearings as shipped is more than adequate for the expected load over the expected life of the printer. I would say that the proof of this is that we have not had countless reports of scored rods, printer meltdowns, houses destroyed, etc., due to inadequate lubrication.

There are still two Big Burning Questions (tm) I would sure like to hear the answers for:

1. What, exactly, is the lube that comes on the bearings? Yes, yes, I have read the datasheet. I would like to hear directly, first-hand, not what someone else heard, from Prusa on this.

2. Does Prusa use any additional lube on the bearings of the machines that go in the print farm when they are first assembled/installed?

RE:

Oh, another "bearing & lube" thread - cool.

I'm with @jsw, my MK3s has about a quarter of his printer's mileage, has been treated according the official instructions and shows no signs of bearing problems.

Let's start another "how to clean your print bed" thread know, shall we?

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

Yes, as 3D printer noob, I am sorry - I should have realized this topic has been discussed to death.

I just could not comprehend why otherwise exceptionally well-made instructions, included such a seemingly obvious mistake. What had I missed?

1) Prusa includes the printed part to do the job properly.

2) The Mini instructions do not have this mistake.

It would have taken me all of 5 minutes to pack the bearing with proper grease instead of leaving the anti-rust oil on. Were I to do it now, it's a 2-3 hour job to disassemble, re-assembly, and hope I don't mess up the alignments. It partially ruined a great build experience.

After about a hundred hours the bearings had already started to squeak, and the rods were bone dry. That's why I started to look into the problem. Thanks to this thread I now realize it will work fine the way it was done, if I just grease the rods relatively frequently for a while to begin with.

Thanks for bearing with me....

RE: Why does Prusa not recommend lubricating the bearings for MKS3+?

I was one of the unlucky ones who had wear/scour marks on the bottom X-axis rod within 100hours of printing. I had not packed the bearings since they were supposedly ok but did "lube" the rods as instructed. Nevertheless, I had the issue and did not know that I could contact Prusa to have them replaced at the time (last year).

Just do like @justme3d said, that if you're not sure, go ahead and pack them. That's what I did on my second MK3S+.

I still check for wear regularly and also make sure that the rods don't feel too "dry".

Hope it helps,

wear/scour marks on the bottom X-axis rod

It's hard to be certain but I get the impression that rod scatches are more often the result of knocking balls out of the bearing during assembly.

Cheerio,