What is the factory measurements?

I live in an area that has temperature variations wherever I put the printer. I got things calibrated once and tried to print a tall object. Well at about 4am in the morning the temperature dropped pretty low and the object got knocked over. So much for long prints. I tried re-calibrating and have had no success so far. Its a first layer issue no doubt. I'm wondering what the factory settings for the PINDA clearance is. I did the adjustments in the manual, but I'm afraid that the tie-wrap shipped might not be the proper thickness. If I adjust it as in the manual, I have to compensate for the Z axis by 0.600 before I get a good first layer calibration. But its not consistent. The manual states that if you have to exceed 0.250 you need to move the PINDA. But I'm only able to move it a thread distance. What is the factory setting?

Best Answer by JoanTabb:

@kevin-15

You see... Resistance was Futile... you have been assimilated by the New Dawn! 🙂

I am however still confused about your Pinda...

My pinda does not hit things and yet My live Z is 1.265 which should make My Pinda about 0.7mm nearer the Build Plate

anyway, give the pinda a bit of love and attention and see how it works...

regards Joan

RE: What is the factory measurements?

Good morning Kevin,

I think there may be a misunderstading... how are you setting your printer up.

your statement about z compensation 0.600 for good first layer and then stating o,250 is too big a value confuses me.

the Prusa printers use a Pinda to initialise mesh bed levelling, after this is complete you should complete some form of first layer calibration

Prusa provide a tool on the LCD Menu, which works, but is not easy to understand.

however ALL Live Z values, are negative numbers (Not positive numbers as you described)

the first layer setup is immensely important as all other actions rely on good adhesion...

you give us very little information, so I will assume that you are using PLA Filament as supplied with the printer...

I will also assume that the printer has passed the self test, and the XYZ calibration and that Z calibration has been completed successfully

To maximise your chances of success,

Please take your removable build plate, to the sink and wash the surface vigorously with hot water, dish soap, and a new (Grease Free) kitchen sponge, or similar... your aim is to make absolutely sure the surface of your build plate is grease and contaminant free. rinse well with hot water and dry immediately with paper towels.

Handle the build plate be the edges to prevent finger prints and put the build plate back on the heatbed.

turn the printer on, and select the LCD Settings Menu, then the mesh bed levelling option, then the 7x7 mesh bed levelling option (this sets the mesh bed levelling to test 49 points on the build plate instead of the normal 9 points that default settings use) (See Page 23 of the userguide found here https://cdn.prusa3d.com/downloads/manual/prusa3d_manual_mk3s_en.pdf )

now complete first layer calibration... the prusa LCD menu option, works but is difficult to get right...

I prefer to use the process found here

the test files are in a zipfile at the bottom of the first post.

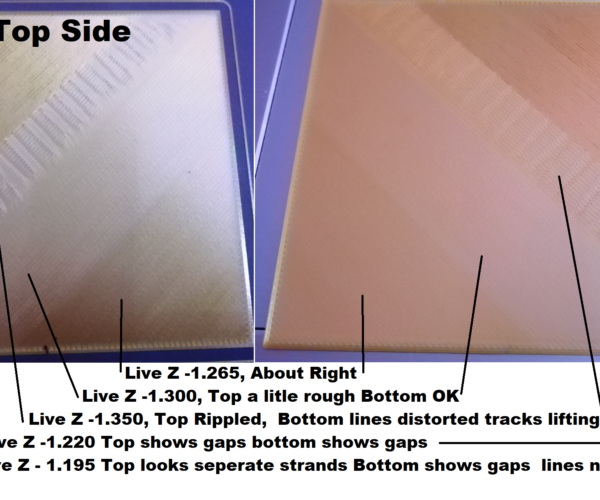

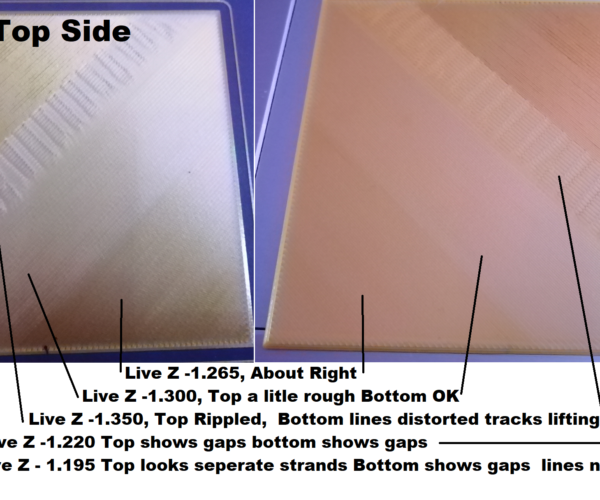

the values in the picture above are for My Build Plate on My Printer, yours may be similar, but are unlikely to be the same...

the images show that small changes in value make significant changes in Print Quality

Please note I use 70C on my Print bed when printing PLA, to improve the adhesion.

I hope this information helps you improve your print quality.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: What is the factory measurements?

I have read several messages in this forum and all will eventually tell you to use dish soap and clean the plate. I surrendered and wore vinyl gloves, used every day dish soap (I was using 409 spray which has additional chemicals), paper towels and washed both sides. I also dried it off wearing those gloves so no finger prints. The first layer went down perfect and I got about 1/2 through the print and nuts.

However, it didn't fail because of lifting or 1st layer adhesion. It was pushed off by the PINDA sensor. I have to put the Live-Z to -0.600 to get the 1st layer calibration to stick. That's why I was asking what the factory settings for the clearance is. Using the tie-wrap as the manual says to, does not provide the proper clearance (the PINDA isn't high enough off the bed). I'm going to move the PINDA up higher and re-calibrate. I think once I do that, the sensor will stop hitting the print. Most of the time I have long running prints. This was the first time I sat for 45 minutes to watch what was going on. I then noticed the PINDA getting way too close and then wham, it hits the print and that was it.

If you are reading this, use regular dish soap and keep that plate clean!

RE: What is the factory measurements?

@kevin-15

You see... Resistance was Futile... you have been assimilated by the New Dawn! 🙂

I am however still confused about your Pinda...

My pinda does not hit things and yet My live Z is 1.265 which should make My Pinda about 0.7mm nearer the Build Plate

anyway, give the pinda a bit of love and attention and see how it works...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: What is the factory measurements?

Locutus, move over...

The manual states that if you exceed -0.250 you should move the PINDA. Ya, that don't work. Not because its the wrong thing to do, you can't get fine adjustment because of that threaded cover (the metal part). What is funny is the manual has -0680 as an example, and then says 0.250 is too much. Anyway, that calibration technique you pointed out worked perfectly. I never had to use a spatula to get my prints off before. I'm going to have to dig out a plastic one so I don't scratch the plate with a knife. I finally set the Live Z to -0.700 and will see how things go. It kept looking to me that there wasn't enough PLA being extruded. Turned out it was the Z adjustment. I'm now getting prints that are solid and not woven (no spaces between the extrusions anymore :-). Thanks for the assist.

Always use dish soap! If you are going to use alcohol, use the human drinkable kind and don't use it to clean the plate.

RE: What is the factory measurements?

@kevin-15

Another convert...

if your build plate fights back you can use the rough side of the sponge with water and dish soap

I have used this on

my smooth Prusa build plates,

Various batch number prusa Textured build plates,

My Prusa Silk Build plate, and on both the smooth side and the textured side of the Chinese 'Energetic brand' build plate, with no noticable damage...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK