UPDATE: Small holes in benchy 3d

Hi forum,

I successfully assembled my prusa i3 mk3s and it passes all the calibration tests. I did a lot of fine tuning with the shipped 3d benchy and now I'm very satisfied with the results.

BUT: I have a problem with the rear of the 3d benchy. There are allways some very small holes on the rear left side in the prints. Here is a picture (red arrows) )

Any thoughts what I can improve?

Bernd

Re: UPDATE: Small holes in benchy 3d

Hi Bernd and hi prusa community,

I have the same issue like Bernd. (see picture below)

I already asked the support, if this was normal. The were really nice to answer me, but I don't understand, what I have to do.

So this Is what I received:

Hello Marcel,

[...]

To the failed prints: Try to loosen the extruder tension strings a bit. Make sure, the extruder is not moving at all - the screws around the bottom bearing on the extruder are tight.

Best regards,

—

* *

Customer Support

I am not quite sure, what these "extruder tension strings" are. And also why the extruder should not move at all, at least the gears should move 😆

To fix this issue it would be an easy solution just to set some "extra length on restart" in Extruder settings of the slicer.

But I am wondering, if I assembled something wrong. Because I printed the pre-sliced Benchy from the SD card, which should print flawlessly, shouldn't it?

So, if somebody has the answer, what I assembled wrong, or if MK3S printers always need some "extra length", pleas help me and Bernd.

Greetings

Marcel

RE: UPDATE: Small holes in benchy 3d

Hi.

Just curious if anyone has found a resolution for this problem. I’m experiencing the same issues with my new mk3s.

Thanks

RE: UPDATE: Small holes in benchy 3d

Hi forum,

I successfully assembled my prusa i3 mk3s and it passes all the calibration tests. I did a lot of fine tuning with the shipped 3d benchy and now I'm very satisfied with the results.

BUT: I have a problem with the rear of the 3d benchy. There are allways some very small holes on the rear left side in the prints. Here is a picture (red arrows) )

Any thoughts what I can improve?

Bernd

I think the support didn't mean "string" but "spring" and that you should adjust the spring tension on the extruder because the extrusion is very irregular. You should also check the "bearing" screws on the backside of the extruder (screws loosened or overtightened).

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: UPDATE: Small holes in benchy 3d

Sometimes this is caused by "wet" or poor filament. If you hear popping sounds at extrusion your filament most likely caught too much humidity from the air. This water then sort of explodes in the hotend and leaves gaps in the print.

RE: UPDATE: Small holes in benchy 3d

Sometimes this is caused by "wet" or poor filament. If you hear popping sounds at extrusion your filament most likely caught too much humidity from the air. This water then sort of explodes in the hotend and leaves gaps in the print.

Yes but moisture in the filament should cause random imperfections. These are all roughly lined up. My guess is this is the layer seam and the issue is showing up during retraction on layer change.

RE: UPDATE: Small holes in benchy 3d

Hi there,

I am also new to the mk3s world and assembled the printer the last days. Everything is calibrated just fine and I also have the same issues with the benchy print from the sd card. The hull of the ship is butter smooth, but I also got those small gaps on the backside, exactly where the printer is changing its layer. I tried loosening the extractor spring as suggested above but it didn't change anything.

Just to understand this issue... is this a common problem when layer change occurs? How can I make it better or remove the problem? I never read about that before actually and I cannot imagine, that this is a "normal" behaviour when printing 3D Models.

I am using the standard grey/silver PLA shipped with the printer itself.

Thanks a lot,

Tom

RE: UPDATE: Small holes in benchy 3d

It's probably not filament - I've tried two different fresh spools of Prusament PLA and one PETG. Given some other repeatable imperfections in different models, I think that it's definitely something with layer lines. Disabling linear advance seems to help, but doesn't resolve the issue. Downgrading to 3.8.1 also helped but did not resolve (probably more LA weirdness).

Prusa support has been engaged, and they've been very patient in troubleshooting the problem. We've worked over the bondtech gears, the PTFE tube installation, hot end heatsink. I've had every axis apart tuning/adjusting/validating tension and bearing tightness. ¯\_(ツ)_/¯

I think that it's in support's hands now. I'll post back when they find a resolution - it looks like there have at least been a few Prusa owners with the same problem.

Can't wait to start printing actual things! I have a whole stack of Lack V2 bits just sitting next to the printer waiting for some proper test prints.

RE: UPDATE: Small holes in benchy 3d

s/layer lines/seams

RE: UPDATE: Small holes in benchy 3d

Hi forum,

I successfully assembled my prusa i3 mk3s and it passes all the calibration tests. I did a lot of fine tuning with the shipped 3d benchy and now I'm very satisfied with the results.

BUT: I have a problem with the rear of the 3d benchy. There are allways some very small holes on the rear left side in the prints. Here is a picture (red arrows) )

Any thoughts what I can improve?

Bernd

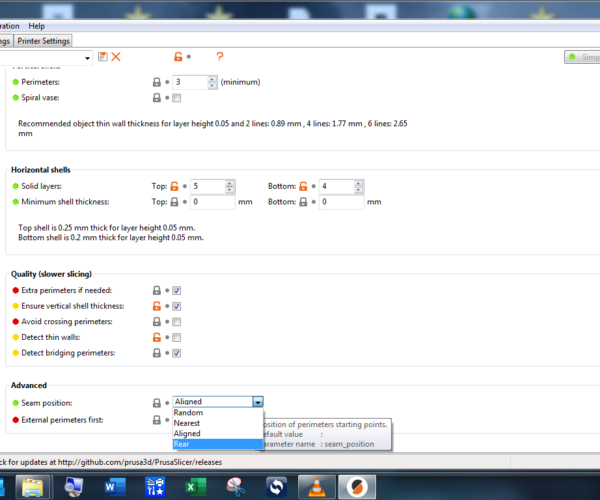

It is also possible that the seam position is in an unfavorable place. Try changing these settings (seamposition):

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: UPDATE: Small holes in benchy 3d

@jcoveycex

Support ended up swapping out most of the extrusion hardware. New Einsy, bond tech, hot end, and motor. Should receive the new parts tomorrow. I’ll post back with the results 🤞

I get the impression that support is not sure what is causing the holes at the seam, but I do appreciate that they are willing to swap out the whole lot of extrusion parts in an effort to solve it.

RE: UPDATE: Small holes in benchy 3d

@msprague

Have you calibrated the LA settings/filament and activated them in the slicer?

https://marlinfw.org/docs/features/lin_advance.html

https://mattshub.com/blog/2017/10/02/linear-advance

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: UPDATE: Small holes in benchy 3d

@karl-herbert

The test prints that I ran were all from Prusa's provided gcode. I would imagine that those should already be well tuned for the mk3s.

RE: UPDATE: Small holes in benchy 3d

@msprague

The gcode is all right. I have also printed the benchy several times without errors. If this is not the case, it is due to the hardware settings of the printer.

These include, for example, the calibration of the extruder, linear adv. settings, pidtuning, first layer, bedleveling etc...

Linear Advance (LA) is a technology that predicts the pressure build-up in the extruder when printing at higher speeds. The firmware of the printer uses that prediction to decrease the amount of filament extruded just before stopping and decelerating, which prevents blobs or artifacts at the sharp corners.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: UPDATE: Small holes in benchy 3d

Well - the saga continues. Mega extruder parts swap did not fix the issue. I will continue following up with Prusa support and see if they have had any luck reproducing the issue.

In the meantime I think that I’m going to dig in to the LA tuning suggested by @karl-herbert and see if I can solve (or at least mitigate) with settings.

RE: UPDATE: Small holes in benchy 3d

@karl-herbert

Do you have any recommendation on whether it’s better to start fiddling with LA tuning in 3.8 or 3.9? Sounds like there have been some changes and challenges in the new firmware.

RE: UPDATE: Small holes in benchy 3d

Just to eliminate surprises: Verify that you're not printing in an enclosure or room with high ambient temps. As temps near 40C/104F, the efficiency of the V6 air cooled hotend drops off. This can affect retractions and those defects are showing at the z-seam where retractions are used.

Try simply slowing down the print as a quick test. Start printing the same gcode, then use the front knob to dial speeds way back (50%). If the problem clears up, you know it's related to feed rates. If you still have issues at slow speeds, something more fundamental is wrong. If this is pre-sliced code that prints well on other printers, you may want to look at issues with the feed path (extruder tension screws, ensure Bondtech idler freely rotates and is fully seated, verify filament path is unhindered).

Try a print with another spool of filament just to ensure it's not a question of saturated filament or something simple.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: UPDATE: Small holes in benchy 3d

Hi guys,

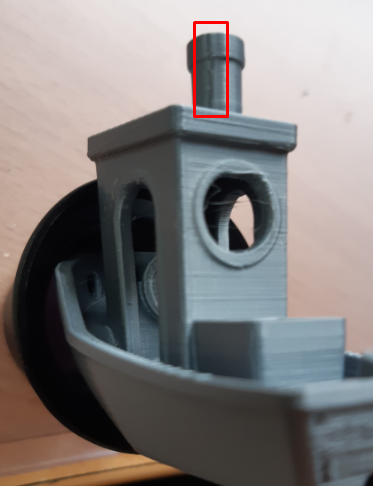

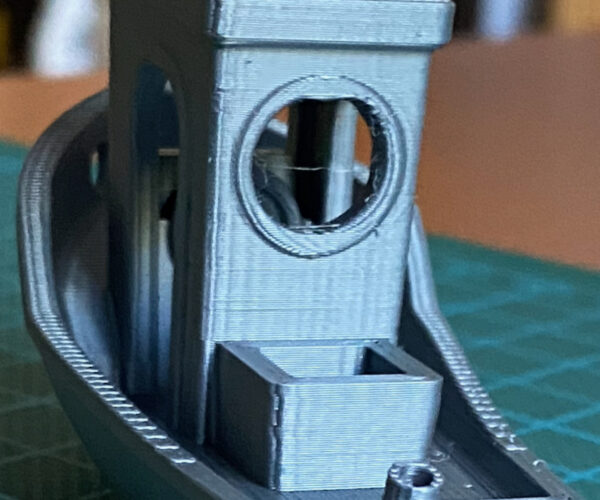

it seems I have the same problem with my newly assembled MK3s... Here is the bench from the SD card:

And this one I sliced with the unmodified settings for MK3s and Prusa PLA .15 and quality with the Prusa Slicer:

As you can see in the comparison, the holes are still there but due to the random placement of the seam not as visible as in the SD-card version. Still obviously a problem with retraction/z-hop.

Did anyone figure it out yet?

regards

Robin

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!