Under extrusion, need help!

Hi everyone, I hope someone can help me. I've had my prusa since December 2018, and it has worked great.

Recently, I replaced the hotend with all new E3D parts -- nozzle block, heatbreak, heat sink. Calibration and setup went fine.

However, i'm having a problem with extreme under-extrusion that starts some time into the print.

I've been running the printer for a while, so I have done all the 'usual things':

- heatbreak, nozzle, ptfe tube, heatsink, block are all new. thermister and heater are still original

- used silicone grease that came with the e3d for heatsink assembly onto the heatbreak

- there is a gap between nozzle and heatblock as there should be

- the bottom threads of the heatbreak come just barely out of the heat block

- tried a cold pull or two-- nothing interesting on the end of the filament

- calibrated temperature

- cleaned extruder wheels, no debris and they turn freely

- extruder fan is running at 4300 rpm, with the label on the inside. i can feel some breeze coming through

- I'm not using an enclosure

- the nozzle was tightened against the heatbreak with the temperature at 280C. there is a bit of gap between the nozzle and the block, so i know it hit the break.

- when i inspect after this happens, i have no filament in the PTFE tube section

- there is no filament leakage anywhere on the block, so i dont think filament is escaping anywhere

- this is an mk3s extruder

- this filament is the same roll i printed tons of stuff successfully before i changed the extruder out.

Here are a few things I have observed that seem odd, however:

- when i disable steppers and push on the filament with a heated nozzle, material does flow freely. but then when i release pressure on the filament, it squirts back out. that's not usual at all.

- when i lower the material temperature, ( say from the usual 215 to 200 for PLA), the print runs longer before it starts underextruding

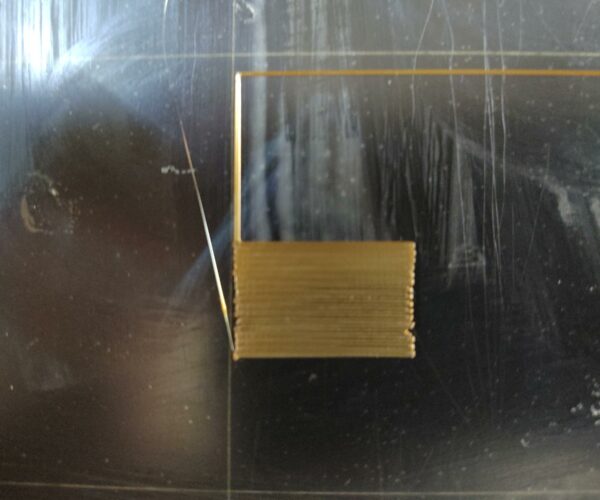

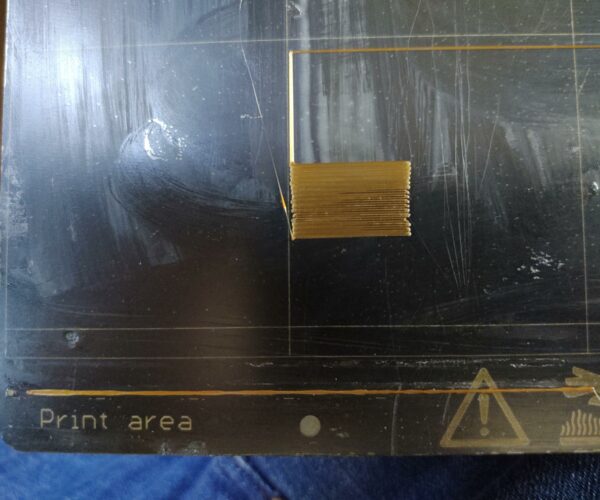

- This isnt a usual kind of jam. its possible to replicate the same results time after time without clearing the nozzle. 1 layer of perfect looking extrusion on the extrusion width calibration cube, and then by the time it finishes layer 2, i have no extrudate coming out

- sometimes i'll see slight underextrusion beginning even during first layer calibration. The solid part will have just hints of it before it even finishes.

- Sometimes even the priming line at the very beginning is underextruded.

This seems like heat creep, but its very fast onset, so it seems like something is VERY wrong.

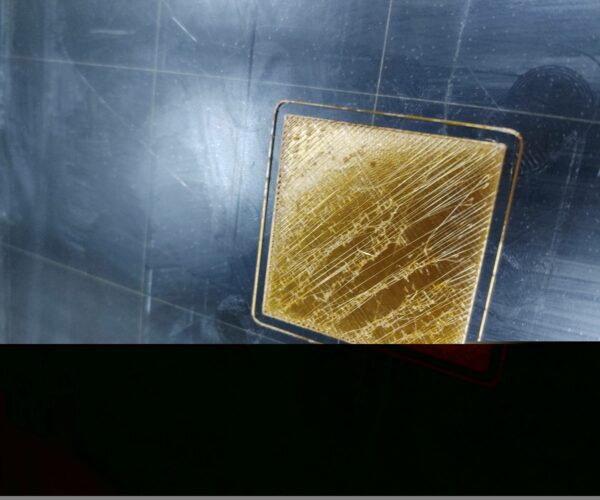

I feel like i must be missing something obvious. Does anyone have ideas? I've attached photos. in this case, you can see the first layer calibration, where the priming line and the solid part are a bit underextruded. In another example, you can see the result of printing the extrusion mulitipler test cube-- which doesnt even make to layer 2. but layer 1 looked perfect!

Tips would be most appreciated!

.

RE: Under extrusion, need help!

You say you have replaced the heater parts and that the nozzle has a gap etc but is it sealed against the heartbreak properly ? Any gap, however slight between the 2 inside the heat block causes uneven pressure which results is behaviour like you describe. The first time I ever replaced a nozzle I made the same mistake and couldn’t figure out why it was printing badly. It wasn’t until I watched a few videos on YouTube that showed the process with diagrams and all the theory behind it that it clicked and I realised what I’d done wrong.

might not be that but it’s a simple thing to check and make 100% sure it’s done correctly with the final tightening at max temp just to have peace of mind.

RE: Under extrusion, need help!

@neophyl thanks for that advice. Yes, i _think_ it was tight, but I'll definitely repeat that process, since it's your guess based on my behavior.

Any particular recommendation on which video is best? I'll google it otherwise.

thanks for the help!

RE: Under extrusion, need help!

Sorry it was awhile a go and I watched soooo many videos at that time.

RE: Under extrusion, need help!

hi, @neophyl:

I disassembled, and re-assembled paying close attention to putting enough torque on the nozzle, with things warmed up to 285C.

Though i thought i'd done that before, you were absolutely spot on-- this seems to have fixed my issue.

Thanks for the help !