Under extrusion causing first layer cal problems?

I have a fairly stock i3 Mk3s that was printing very well but I recently had a print fail where the hotend was smothered in molten plastic. No problem I've replaced the heat block, heater cartridge, thermistor, nozzle, and heat break. I am now having severe problems getting anything to stick to either sheet.

I've noted that the extruded plastic during the first layer cal process is only 0.2mm thick and not 0.4mm. If I raise the z and just extrude plastic using Settings, Move Axis, Extruder the extruded plastic is o.5 mm, perfectly smooth, and nicely round.

I can't seem to improve this situation much even by increasing the flow to 130% (the extruded plastic is then at about 0.3mm. I can't see how I can achieve a successful first layer with so little plastic! I've cleaned the nozzle and done a cold pull to no effect.

I'm at a complete loss here folks any help would be much appreciated.

RE: Under extrusion causing first layer cal problems?

The thickness of the first layer should be 0.2 mm thick and nothing else!

So reset any changes you have made to the print profile and everything should work.

If you have changed the extruder, you only need to calibrate the first layer again so that it is tight and fine.

Bear MK3 with Bondtech extruder

RE: Under extrusion causing first layer cal problems?

The thickness of the first layer should be 0.2 mm thick and nothing else!

So reset any changes you have made to the print profile and everything should work.If you have changed the extruder, you only need to calibrate the first layer again so that it is tight and fine.

I realise that the layer should be 0.2mm thick, but that should be achieved by the nozzle pressing a thicker bead of plastic down onto the plate so that it spreads and joins with the bead beside it. My problem is the bead of plastic extruded from the hotend is already 0.2mm thick leaving nothing to be pressed into the plate!

RE: Under extrusion causing first layer cal problems?

Can you provide pictures or first layer?

Smooth or textured sheet?

With the nozzle away from the print bed and you manually extrude filament does it come out smooth and consistent?

RE: Under extrusion causing first layer cal problems?

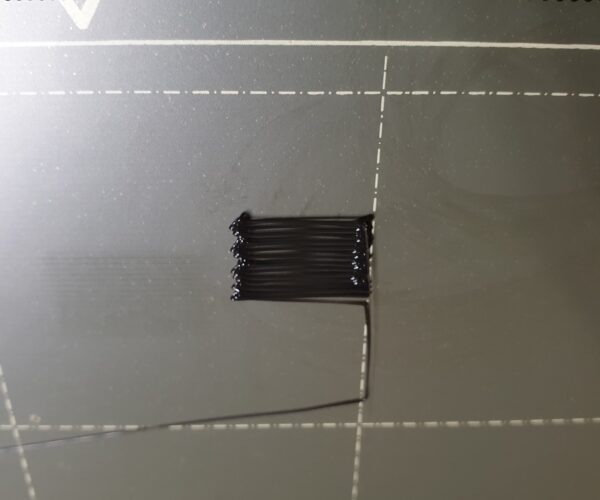

As you can see, it's on the smooth plate (which is new), the strands of plastic going from left to right are only 0.2mm in diameter. Extruding plastic away from the sheet is smooth and 0.5mm in thickness. The Z offset was at -1.265.

The Z calibration went without a hitch with the sheet of paper being touched but still easily moveable throughout the process. I've done this several times before without issue. I intend to cold pull the hotend a couple of times just to make sure it isn't compromised but it is all new, I even changed the silicon tube this pm just in case!

RE: Under extrusion causing first layer cal problems?

Looks like you need to work on the first layer, the nozzle is too far away from the bed.

See if this helps.

https://rumble.com/vb9fxr-3d-printer-first-layer-calibration-process.html

RE: Under extrusion causing first layer cal problems?

Unless I can get more plastic out of the nozzle I'll never get a first layer!

RE: Under extrusion causing first layer cal problems?

It looks like plenty from the pictures, just needs to be quashed down on the plate. You might need to readjust the PINDA probe. If the Z offset was at -1.265 during that first layer calibration from the pictures feels like it may be mounted too low.

Also from the pictures looks like the plate could use some cleaning.

RE: Under extrusion causing first layer cal problems?

@gkmakeit

Thank you, the PINDA probe was indeed too low! I now have a great first layer with a setting of -0.600!

RE: Under extrusion causing first layer cal problems?

Great to hear! Time to print!