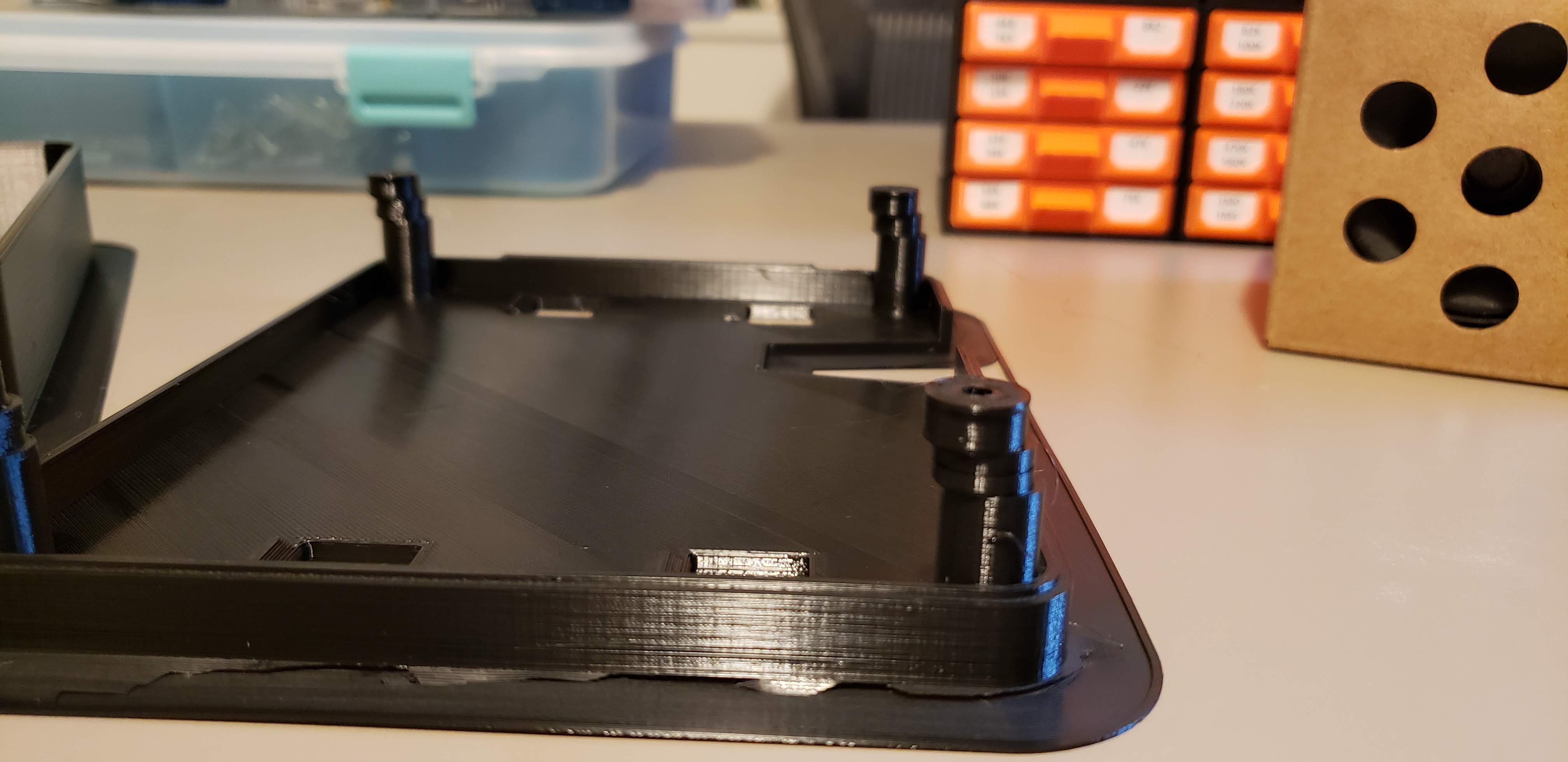

Ugh - Layer shift near print finish

Is this something where I should attempt to tighten the Y axis belt? See image. My belt values are X:276 and Y:280.

The shift looks like it is mostly in the Y-axis direction.

RE: Ugh - Layer shift near print finish

Note: I was using the 0.20 mm Quality PETG profile.

Another option might be to reduce the travel speed from 180 mm/s ?? I want to try again at that speed, but curious if I should mess with the belt(s) first...

RE: Ugh - Layer shift near print finish

Mess with your bearings - they are probably the culprit. Too much friction and things are seizing up.

RE: Ugh - Layer shift near print finish

Also check if both the screws on your toothed pulleys on the motors are firmly tightened.

RE: Ugh - Layer shift near print finish

Also check if both the screws on your toothed pulleys on the motors are firmly tightened.

Well - the order in which the set screws are tightened is very important. Otherwise they come loose. But the print doesn't look like it is a loose pulley or belt.

RE: Ugh - Layer shift near print finish

It looks like slippage during the rapid movements that occur near the top of the print. Others have already mentioned the common culprits. If the shift is exactly equal to one belt tooth, then suspect belt slippage. This could be due to loose belts aggravated by bearing friction. Stepper motors stalling during rapid movement would likely create random offsets.

Steve

RE: Ugh - Layer shift near print finish

Pulley and belt slips are generally bidirectional.

But, there is also a known defect in the firmware that can cause this to happen (v3.8.x).

RE: Ugh - Layer shift near print finish

This is all good info...

To add to the issues - the part pictured here was the rear housing for an enclosure I made, and I had printed the front half of the housing before this. I noticed that the front housing also had a layer shift (much earlier in the print) that I didn't notice until I was removing the brim material last night.

I ended up tightening up the belts (both X and Y) - Y seemed a bit loose by visual and touch inspection. I did NOT mess with the bearings (YET) as I wanted to change just one thing at time. I ran a new print for the front half of the housing last night and it came out with no issues. I am printing a new rear housing right now (with the long bosses).

I will do a search here momentarily - but what is the firmware defect referred to above?

RE: Ugh - Layer shift near print finish

RE: Ugh - Layer shift near print finish

My guess would be hitting a cable or zip tie in the Y axis transit.

Easy enough to verify no obstructions under the carriage.

And watch the extruder cable at about that elevation...

RE: Ugh - Layer shift near print finish

(I also slowed my travel speed down from 180 mm/s to 100 mm/s)

RE: Ugh - Layer shift near print finish

@robert-rmm200

I will check that too...

Pretty sure that it isn't anything under the bed, since I was just poking around under there when I tightened up the belts, but your comment reminded me that I do get occasional "snags" of the extruder wire bundle with the heatbed bundle with the bed and extruder are in a specific location. (The edge of the "wrap" catches on the edge of the "wrap" for the other bundle.)

I will elevate the extruder to the height where the first shift occurred and look for issues.

RE: Ugh - Layer shift near print finish

@robert-rmm200

I will check that too...

... I do get occasional "snags" of the extruder wire bundle with the heatbed bundle with the bed and extruder are in a specific location. (The edge of the "wrap" catches on the edge of the "wrap" for the other bundle.)

This is a sign your 3mm nylon is not installed properly. The extruder harness should never come near the bed harness.

RE: Ugh - Layer shift near print finish

@robert-rmm200

I will check that too...

... I do get occasional "snags" of the extruder wire bundle with the heatbed bundle with the bed and extruder are in a specific location. (The edge of the "wrap" catches on the edge of the "wrap" for the other bundle.)

This is a sign your 3mm nylon is not installed properly. The extruder harness should never come near the bed harness.

The print bed has an alternate 45 degree cover for the connection to the heatbed to create enough room for the printer to fit in an Ikea Lack enclosure. Perhaps that is what causes the contact? I can see how there would be less chance for contact if the bundle exited the heatbed straight back.

I did adjust the wrap (which wasn't fully tucked around), so it doesn't "snag" anymore, but it can still touch in certain situations.

The prints that I have run since adjusting the travel speed and tightening the belts haven't had any further issues.

Here is a link to a video I just recorded of the printer in operation:

https://photos.app.goo.gl/jhuztc45RFYyXFHM6

Thanks

RE: Ugh - Layer shift near print finish

Your heat bed wire is coming off the wrong side. The cable should head left, not right. And, that doesn't look like a factory cable cover, either. The stock cover directs the cable straight back. In any case, cables should never interfere with each other.

RE: Ugh - Layer shift near print finish

Tim that looks just like the cable cover on mine (arrived around this time last year) and when its fully left part way back it does get very close together, there's about 1mm of clearance so I'd say it looks pretty normal.

RE: Ugh - Layer shift near print finish

Your heat bed wire is coming off the wrong side. The cable should head left, not right. And, that doesn't look like a factory cable cover, either. The stock cover directs the cable straight back. In any case, cables should never interfere with each other.

The bundle covers are 100% stock - this is what came with my printer (MK3S) which shipped around the beginning of July 2019.

And I am not sure what you mean by the heatbed wire should exit to the left - this would cause them to interfere with the Einsy board wiring that exit at the bottom.

I can't find the exact version that I used, but this one is similar:

https://www.thingiverse.com/thing:2890592

I will try to find the file I used for the bed connector cover later today - I am curious if anyone has commented about the interference. Maybe that is just the price one pays to make this thing fit in the Lack enclosure.

RE: Ugh - Layer shift near print finish

Heat bed connector and cables look just like mine. Well mostly - my connector is a different one.

There are certain points where the cables touch - but nothing hangs up.

I would be careful that the heat bed cable does not flex about an inch away from the connector. That could lead to wire breaks.

Sheath should be tight enough that all movement is smooth.

RE: Ugh - Layer shift near print finish

Heat bed connector and cables look just like mine. Well mostly - my connector is a different one.

There are certain points where the cables touch - but nothing hangs up.

I would be careful that the heat bed cable does not flex about an inch away from the connector. That could lead to wire breaks.

Sheath should be tight enough that all movement is smooth.

I think I got rid of the snagging by tightening up the wrap. It wasn't fully tucked so the edge was exposed and "proud" of the bundle, creating a sharp-ish edge that could lightly grab the extruder bundle wrap.