Top layer issues (not printing smooth)

Hey y'all,

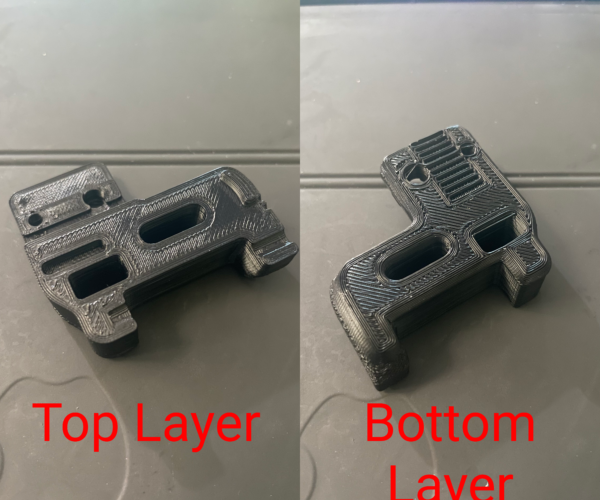

So I recently built an enclosure for my MK3S+ and have been printing ABS. It's just that the top layers look like this and they are kinda rough. I initially thought it has to do with the z offset and now I have lifted my z to a point that I see actual gaps in the base layer but the top layer still looks like the nozzle is grinding through it.

Can someone please help me figure this out. I don't want to use the ironing feature.

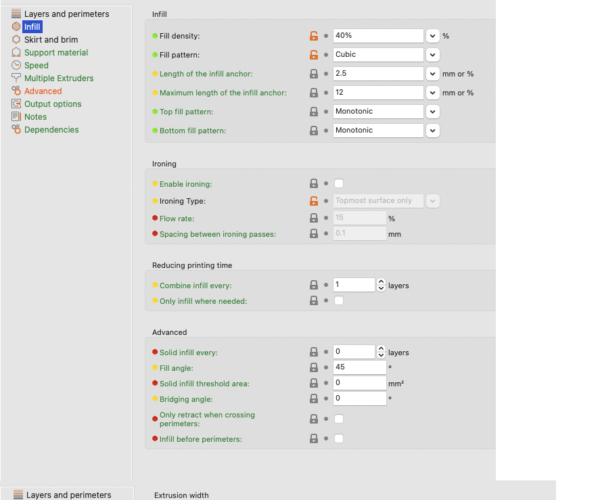

Print settings:

RE: Overextrusion

When adjusting the Z-offset you're just lifting your whole part away from the printbed. This won't help you. To me it seems clear that you're slightly overextruding. There's too much material pushed out the nozzle which is spilling out next to each lane and the nozzle is burrowing itself through it. Try adjusting the extrusion multiplier and make sure that the correct filament diameter is set. Also set the Z-offset back to a value so the nozzle is closer to the printbed.

Will experiment

Thanks @the-powl I have addjusted the z-offset to the original position and will experiment with reducing the extrusion multiplier.

Thing is, I have done the E steps calibration and it seems to be perfect and then I followed that with the slicer flow calibration as well. Both come up with perfect values. That's why I haven't messed with the extrusion multiplier so far.

When adjusting the Z-offset you're just lifting your whole part away from the printbed. This won't help you. To me it seems clear that you're slightly overextruding. There's too much material pushed out the nozzle which is spilling out next to each lane and the nozzle is burrowing itself through it. Try adjusting the extrusion multiplier and make sure that the correct filament diameter is set. Also set the Z-offset back to a value so the nozzle is closer to the printbed.

Top layer flow rate

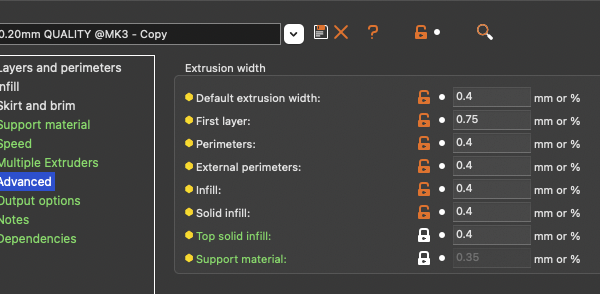

I changed the advanced settings to 0.4 and got better results. The section that says Top Infill %, is that how you change the top layer flow rate?

When adjusting the Z-offset you're just lifting your whole part away from the printbed. This won't help you. To me it seems clear that you're slightly overextruding. There's too much material pushed out the nozzle which is spilling out next to each lane and the nozzle is burrowing itself through it. Try adjusting the extrusion multiplier and make sure that the correct filament diameter is set. Also set the Z-offset back to a value so the nozzle is closer to the printbed.

Extrusion multiplier

The extrusion multiplier is under Filament Settings > Filament.

Mk3S+,SL1S

Only the top layer setting is missing

Yes and I am going to experiment with it in a few.

Other slicers like the Super Slicer have a setting to edit the extrusion multiplier specifically just for the top layer and not universally.

Was wondering if we an make Prusa Slicer do the same because I don't want to hop slicers for my MK3S+

The extrusion multiplier is under Filament Settings > Filament.

RE: re

You could use gcode to change the flow rate at a specific layer. Be careful, this value will persist to the next print unless you change it back. See https://marlinfw.org/docs/gcode/M221.html

You slice and then in the column at the right on the preview page you right click on the layer you want and select add custom gcode.

Mk3S+,SL1S