Surface finish issues with MK3 kit (S3D and Slic3r)

Hi. I finished assembling my MK3 kit last week and in my testing, I'm having some surface finish issues on my prints and I was hoping someone could guide me in the right direction. I have seen similar issues in both Simplify3D and Slic3r so I'm not sure if this is a slicer settings issue or possibly a hardware issue.

These are photos from a test print on S3D. Both are printed at the same time next to each other since I don't normally print just one thing at a time, its a good test for me.

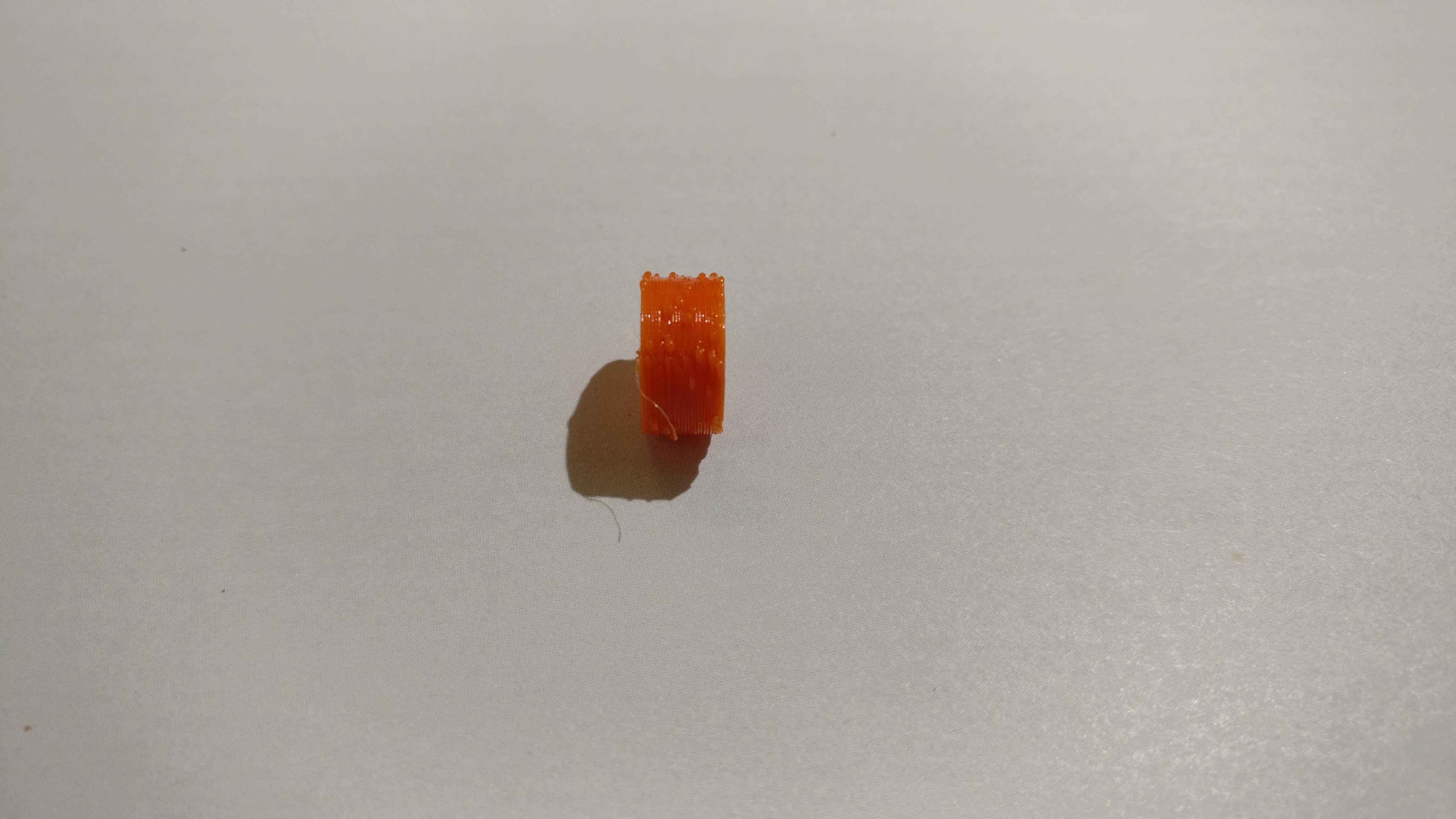

It looks like "ziting" or small bumps, only inverted

And when I print with Slic3r I get better results but a similar issue.

These look similar. The surface finish seems much better but it looks like the issue is reversed very slightly so now there are small bumps ("zits") on the outside on the model.

In both slicers, I have "Random Start Points" set because otherwise, it will leave a very obvious line where the extruder moves between the parts. And it does that in both S3D and Slic3r. (I don't have photos of those prints since I just threw those test prints away)

I've also attached the S3D profile and the Slic3r profile so if anyone wants to look at them they can and the two models I have been printing for my tests. (Just a 10mm and 20mm cylinder.) They are all in a .zip since I can't attach the files themself. The Slic3r one is slightly changed from the default and the S3D one is a slightly more edited version of one I downloaded from a forum.

And if anyone wants to know, all these prints have been printed using the PLA that comes with the printer and I have checked that my extruder is calibrated

Any help or guidance is greatly appreciated and if its a slicer issue, I would quite like to get S3D fully working since...well I paid for it! And I do like it a lot. This is not a issue I ever remember having on my old printer, so I'm kind of stumped right now.

Edit: The prints in the photos were printed over USB, but I have seen the exact same issue when printing from a SD card (included one). I'm also running the latest Firmware.

Re: Surface finish issues with MK3 kit (S3D and Slic3r)

Hi,

I had the same problems the last days and tries many hours to fix it.

I noticed, that the printhead was not performing the circular movements completely. It was stopping several times during the printing of one layer and that was the reason for those drops on the print.

It only happened on circular objects. All straight lines were perfectly fine.

I was using Octoprint on a Raspberry Pi Zero W, mounted directly to the Rambo board via the GPIO pins.

After 20 tries with all differnt settings there was no change at all.

My last try was to print it directly from the SD card and with that, there were no problems at all.

Maybe also try using a faster SD card (class 10).

I attached my profile (it is almost the default one, except the support material and more top and bottom layers) and the stl and gcode file of my small test cylinder.

EDIT: The page would not let my attach my zip file including the 3d files. Therefore is here a direct link to is: Slic3r_TestCylinder.zip

PLA Version which i printed earlier. This does not have a huge amount of issues.

The PETG version of my test cylinder printed from Octoprint. Here is the size of the drops visible.

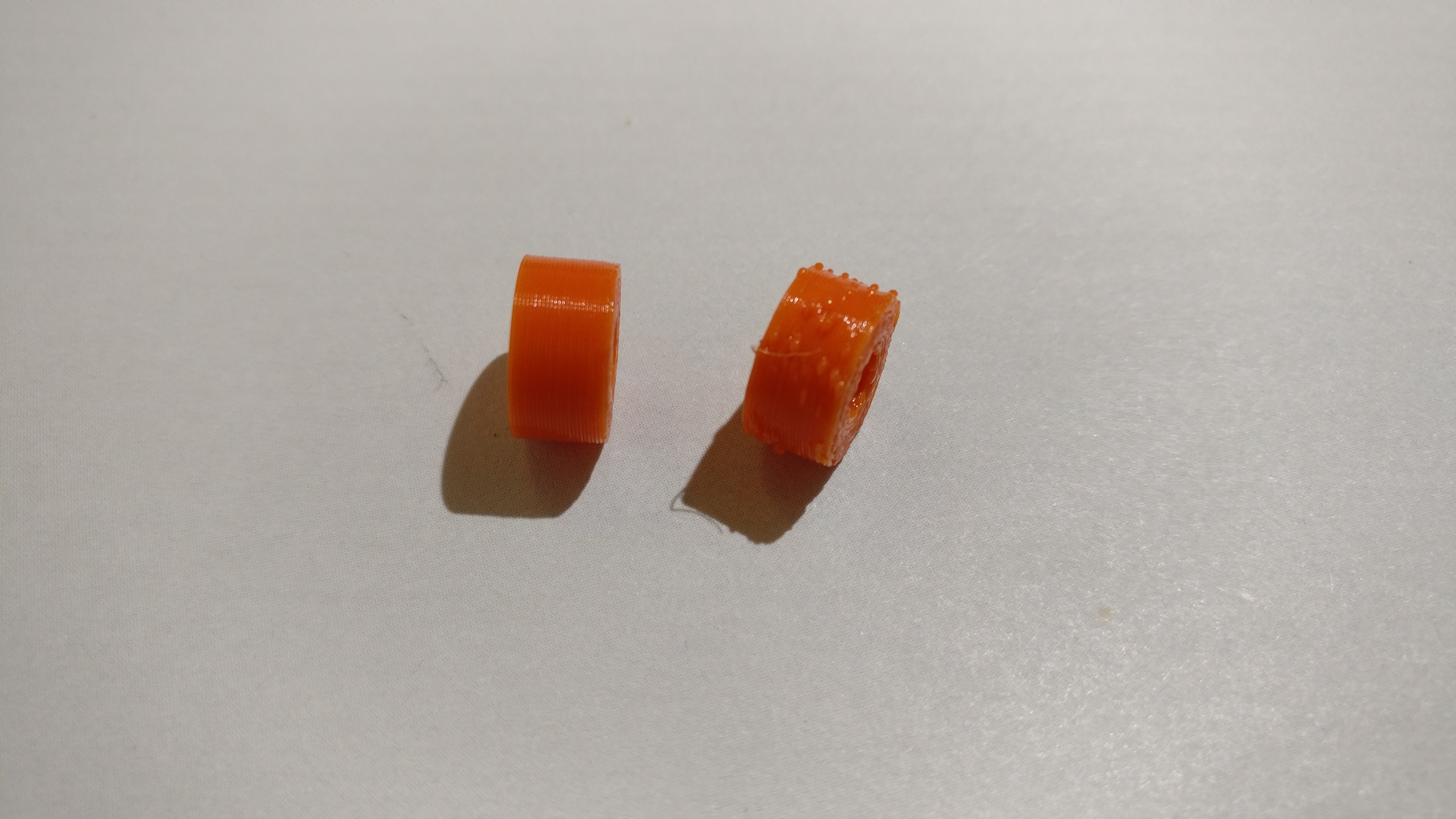

On the right hand side, the on printed with Octoprint, on the left hand side, the same gcode printed from the SD card.

I hope this will fix your issues as well.

Re: Surface finish issues with MK3 kit (S3D and Slic3r)

Hi,

I had the same problems the last days and tries many hours to fix it.

I noticed, that the printhead was not performing the circular movements completely. It was stopping several times during the printing of one layer and that was the reason for those drops on the print.

It only happened on circular objects. All straight lines were perfectly fine.

I was using Octoprint on a Raspberry Pi Zero W, mounted directly to the Rambo board via the GPIO pins.

After 20 tries with all differnt settings there was no change at all.

My last try was to print it directly from the SD card and with that, there were no problems at all.

Maybe also try using a faster SD card (class 10).

I attached my profile (it is almost the default one, except the support material and more top and bottom layers) and the stl and gcode file of my small test cylinder.

EDIT: The page would not let my attach my zip file including the 3d files. Therefore is here a direct link to is: Slic3r_TestCylinder.zip

IMG_20180730_124636.jpg

PLA Version which i printed earlier. This does not have a huge amount of issues.

IMG_20180730_124651.jpg

The PETG version of my test cylinder printed from Octoprint. Here is the size of the drops visible.

IMG_20180730_124714.jpg

On the right hand side, the on printed with Octoprint, on the left hand side, the same gcode printed from the SD card.

I hope this will fix your issues as well.

Thats incredible that you are getting that much difference between Octoprint and printing from a SD card. I don't know if that is related to my issue since the photos are from prints over USB from my computer and prints from a SD card have the same artifacts/defects.

I'll update my original post so it says they these are from printing over USB, but I'm so glad it's not just me.

Edit: sorry, I just reread your post and read it correctly this time 🙄

Re: Surface finish issues with MK3 kit (S3D and Slic3r)

Those look like the transitions between layers, often referred to as the "seam". In Slic3rPE, take a look at Print Settings->Layers and perimeters->Advanced->Seam position. Going by your prints, it is most likely set to Random. If you slice the model in Slic3r and look at the preview, you'll likely see small gaps in each layer where those appear. Here's an example:

[...] Thats incredible that you are getting that much difference between Octoprint and printing from a SD card. I don't know if that is related to my issue since the photos are from prints over USB from my computer and prints from a SD card have the same artifacts/defects.

These occur when one line finishes and the next begins. You can mitigate them somewhat, but not eliminate them completely. If you change it to one of the other settings, the zits will be more-or-less aligned. The other settings will allow you to hide them in a corner, if one is available, but they do have to go somewhere:

On a cylindrical shape, the best you can do is try to hide them. Here I've set the seam position to Rear:

If you are running recent firmware, Linear Advance should be enabled. In Slic3rPE, take a look at Filament Settings->Custom G-Code-Start G-Code. You should see a line like:

M900 K{if printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}200{else}30{endif}; Filament gcode

This example is for PLA. This is setting M900 K30 (for a stock Mk3). Linear Advance automates some of the work required to try to fill in the end of a line and prevent blobbing at the start of the next by anticipating nozzle pressure. As a result, Slic3rPE lacks some of the features provided by other slicers for tuning this issue. You could try reducing Filament Settings->Filament->Extrusion multiplier slightly.

Try these things to confirm you can at least line up the seam. If so, there may be a few more tricks you can try to reduce it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…