Suddenly bad stringing with PLA

It was really flawless before a printing some days with TPU... well i needed to print some stuff with TPU Printing with PLA was like a charm before, also printing with TPU was nearly stringing free and no problems at all. I was really excited about how awesome it was with the TPU (Sainsmart)

When i switched back to PLA i could not really Print at all, because of the stringing and oozing it mostly ripped the first layer from the print bed because there where some blobs and the nozze picked it up. I am not sure how can i resolve this...

i tried to fasten the extruder tension and lowering it again but wont help also cleaning the nozzle was no help well from outside... i did a cold plug well maybe someone can direct me in the right direction...

sorry about my bad english

Things that can cause stringing in PLA

In my experience, stringing is a function of temperature and retraction. If you are using default settings in the slicer, and didn't adjust anything (try taking everything back to stock) it shouldn't be an issue unless you are using a low temperature PLA. I always check the box that the filament came in to determine recommended printing temps. Even different colors from the same brand can have different temp requirements.

Also, if your nozzle is gooed up, or your first layer Z is too low, you can start a stringing fit that is due to build up on the nozzle. If the nozzle is clean, slowly try lowering your print temp to reduce the stringing. If you need to after that, increase the retraction distance slightly, or reduce the extrusion ratio by .1 or .2

RE: Suddenly bad stringing with PLA

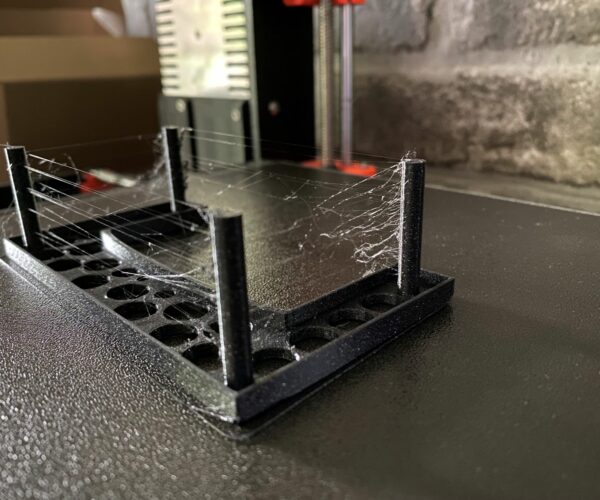

the pictures are Prusament galaxy Black with the standard slicer settings. i tried already playing around with the retraction settings well only once that one but also lowering heat and raising heat but same results...

the first layer calibration was always perfect until now i can a perfect setting for the little end plate but the longer strings are getting ripped from the bed because of the stringing

ah also it a bit of a luck game if i get through the first 3 layers because of the problems the stringing or blobs are producing

Be sure filament is dry

If everything printed well before, I wouldn't suspect sudden mysterious settings or hardware problems. Before changing any slicer settings or (shudder) hardware, I always make sure my filament hasn't simply absorbed some moisture. Even PLA can absorb moisture if environmental conditions are right (e.g., high humidity). I'd dry the spool or at least replace it and try again. If you still experience problems after drying, then look into making changes.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

thank you will try that tomorrow but i doubt that that will be the problem ... my filaments are stored always in a dry pack i kept especially that one for two years in a bag and it printed almost a month now really good and the room were the printer stands is climate contrrolled so low humidity in general..

but will try it 🙂

Let's try some more obvious stuff them

Since you were printing TPU, and TPU requires you to loosen the extruder gears - is it possible you didn't re-tighten your extruder gears? If the gears are not set right, retraction won't work as expected - which could lead to stringing.

yeah thank you but i tried that... different strengthend tries...

i will try later a new pack of filament also i ordered a new nozzle since i assembled the printer (was one of the first) i did not change the nozzle at all, if also maybe i disassemble the extruder a bit...

i will report back what helped 🙂

Yikes

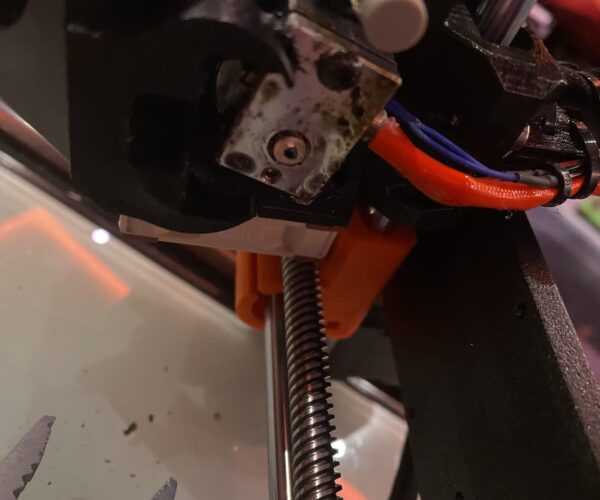

So sorry to see you are having that nozzle broken like that. Do you know what you did that broke it instead of unscrewing it - it would be helpful to others to know what to not do...

yes of course...

it was completely my fault i was watching this video from Josef: at 0:32

and only i did remember it slightly as there was no further notice to heat the nozzle before, so i just tried to unscrew it with no preheating.

Also the screw for the heater i could not open and decided then to order a complete assembled new hotend.

Well i checked then every part from the print head so it can not be the exrtuder or anything there for the stringing, the stringing is now not that bad as it was on the first pictures but still there... well not that bad is kind of okay a little bit with a heat fan and all is gone.

well with the broken nozzle it was my fault and the stringing maybe the bondtech drive gear losend itself because it fell from the motor when i disassembled it... well it was there for 3 years around.,.. so of course there can be some losend screws 😉