Stuck in the First Cal. Layer zone

Hi everybody,

It has been approximatively one month I've received my MK3 kit, and i'm kind of lost in First Cal Layer zone.

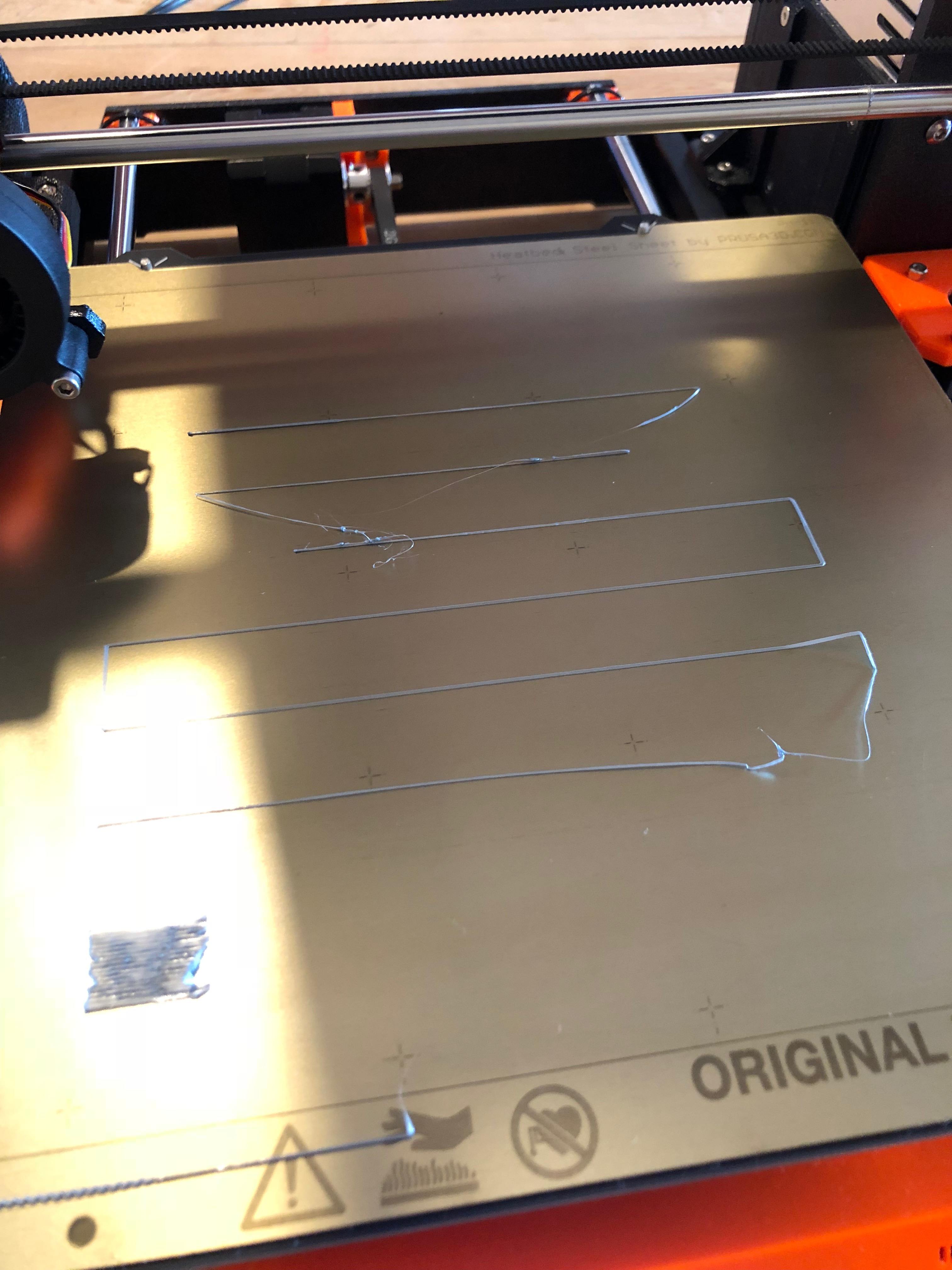

I had no problem during the kit assembly, I've done all the tests with success, and when I arrive to the First Calibration test it's began to fail ever after....

I'll follow the step of First Cal. on internet and watched the video, trying to set the Z

at a correct level to have a sticky and fine first layer, but it never happen. Either it was to thin or when I raise it, the Pla won't stick on the bed (flat steel sheet/gold) and the Pla agglomerate around the nozzle or else worst.

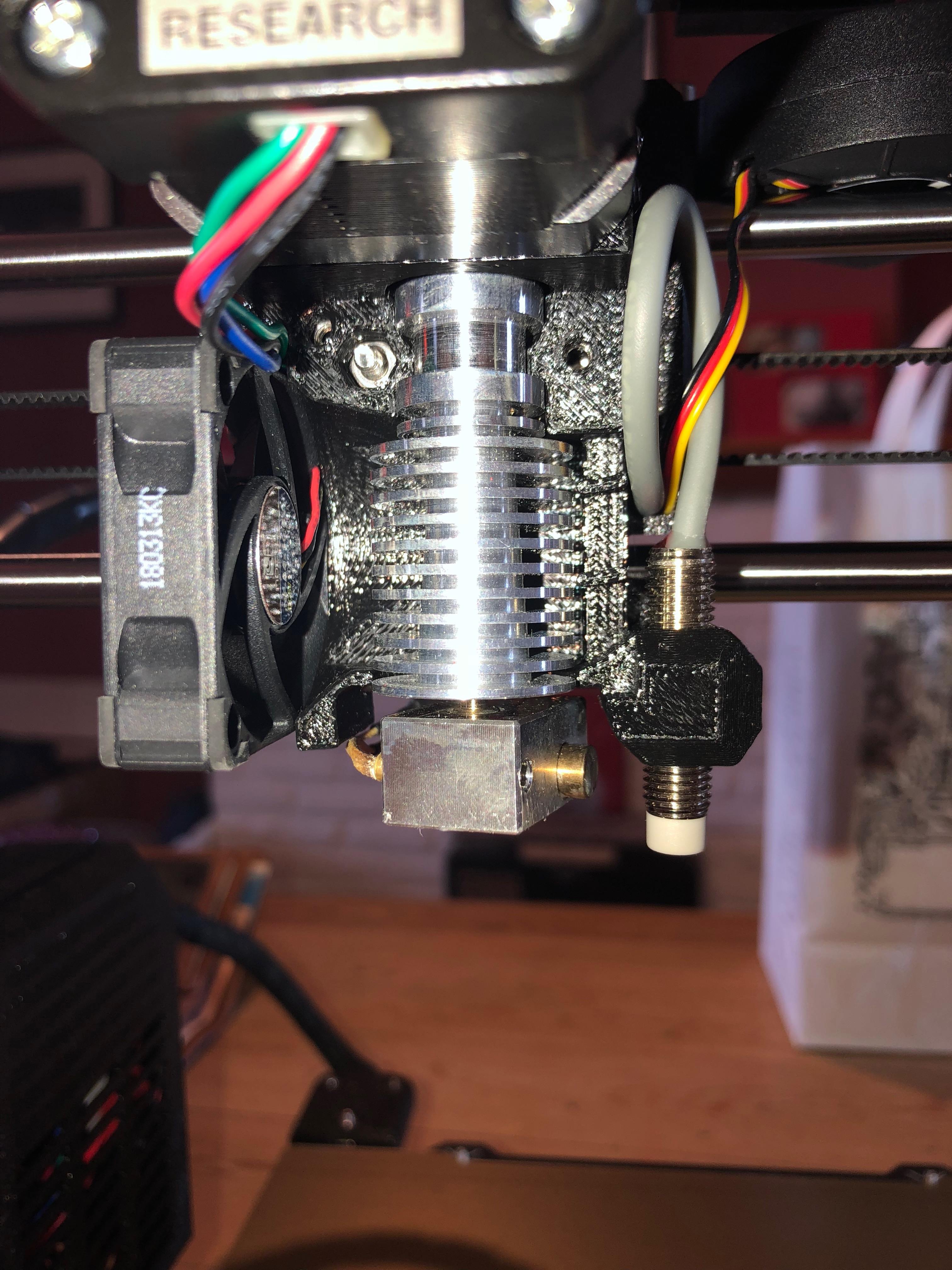

After some repeated F.C. tests, I had a temperature problem. Temperature sensor does seems to give false info to the printer. Who had the consequence to overheat the nozzle, which never reached the setting temperature. At that moment I've cut the zip ties and checked twice every cables and it finally became normal.

After that I've continue to achieve a proper First cal. layer but with no result. Following some tips in the help forum, I reinstall the firmware, unmount the nozzle and clean it, unmount the extruder

to see if the overheat had damage the extruder support and try the other First cal test with the 75x75 forms. I had a better result with the 75x75 (at -1095mm

)

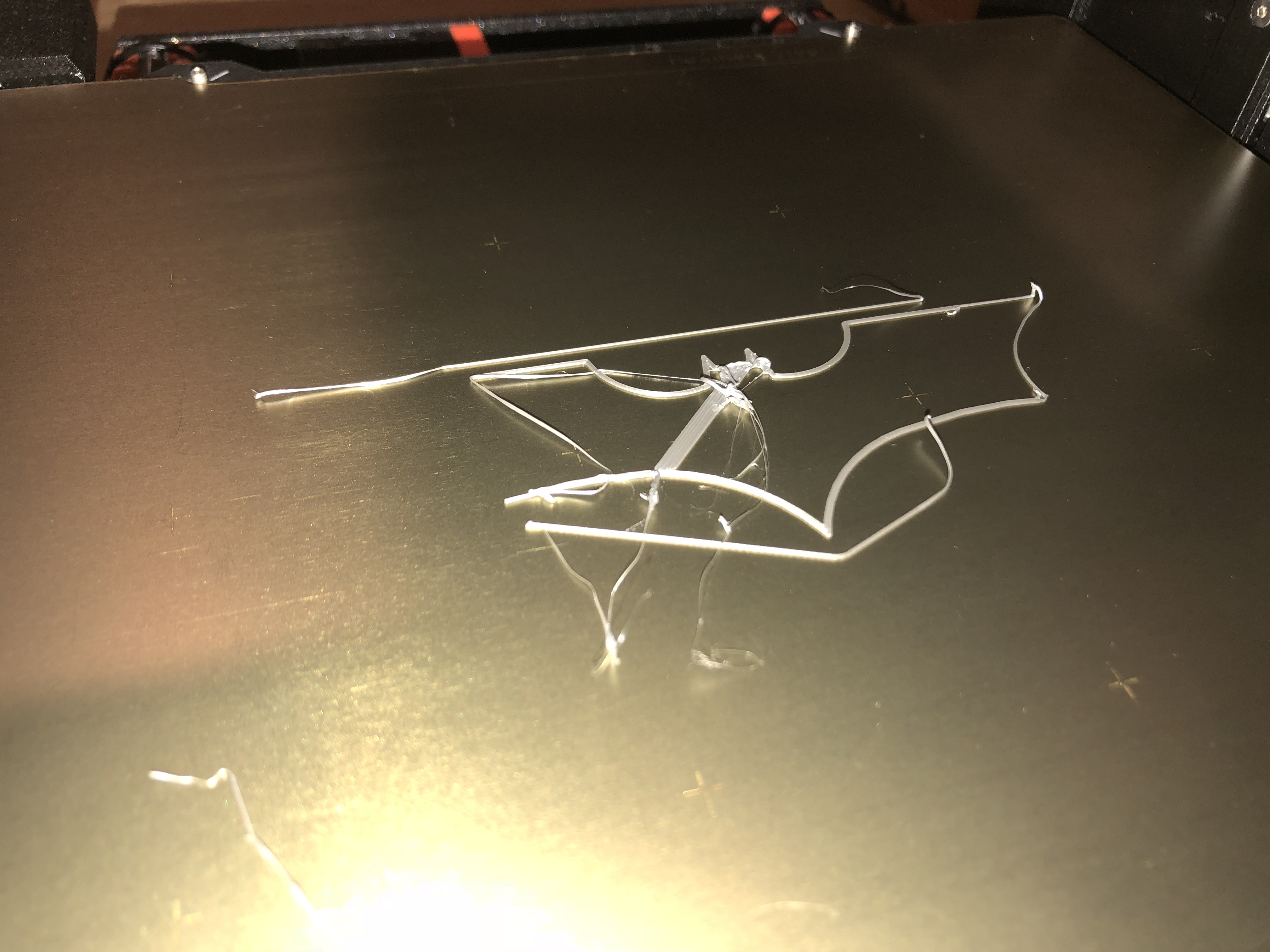

but when I pass to the print (I've tried the batman logo) it's a disaster....

So now I don't really know what to do next ? Any Ideas ?

Re: Stuck in the First Cal. Layer zone

Your Z level is too high, which means that the filament does not attach to the bed (a bigger negative value).

However, you should not have a value greater than -1000 (preferably -500 to -600), so you should correct the height of your PINDA before the next calibration.

Bear MK3 with Bondtech extruder

Re: Stuck in the First Cal. Layer zone

I was thinking the same, I forgot to tell in the previous message, but I also tried to change the PINDA height. I had the feeling that either it's too high or too lo, even if I change it of one click. I had tried to be close to the bed, but during the XYZ cal the nozzle slightly moved the paper so I stop the sequence, move the PINDA again to have this -1095 result ? It seems there's no in between...

Re: Stuck in the First Cal. Layer zone

Moving the PINDA one click moves the sensor 1 mm because the thread has a pitch of 1 mm. If instead you turn the PINDA half a turn, the height changes 0.5 mm, which should suffice.

Bear MK3 with Bondtech extruder

Re: Stuck in the First Cal. Layer zone

Hi thanks a lot for your response,

I tried to move the PINDA like you said, and during the calibration the better result seems to be around -770mm, but the printing is never the same. I use the 75x75 method and does the live adj from -795 to -715mm (square at the left of the picture) then choose -770mm. Made a new printing with this change and it was completely bad, since the beginning. So I canceled it, restart it again and the second result is better but not great ? Is there anybody from prusa here for that type of problem ? It should not be so long to calibrate ? no ?

Re: Stuck in the First Cal. Layer zone

Finally I've succeeded to print a 75x74 -800mm correctly

So take my chance and try the Batman print who appears to be like that

several time.... how can it print the -800 good and just after make some crap ???

Still no chance to make that machine work, this is beginning to be really frustrating !!!

Re: Stuck in the First Cal. Layer zone

Your live-Z looks fine. I would say the issue is now bed cleaning. If you are using 99% alcohol to clean the bed (and make sure that there is no oil from fingers on bed) then move to next level for cleaning: warm water with dish soap and then do alcohol again once dry. Next level up is acetone and then alcohol.

Re: Stuck in the First Cal. Layer zone

Thanks Gaston, I'll try that. I now use 96% ethelic alcohol instead of 99% and I did not try acetone yet

Re: Stuck in the First Cal. Layer zone

I recently got new brand of filament and it simply wouldn't stick even though my MK3 is dialed in nearly perfectly. I had to drop 1st layer temp way down to 200 after reading the manufacturer's recommendation, suddenly it sticks like glue.

Re: Stuck in the First Cal. Layer zone

Hello and thanks Pathogen,

I was thinking about temp also after some reading on the forum, but here it's the silver Pla ordered with the kit from Prusa so I hope the temp is correct :). I will try to lower (or raise) the bed temp too see if it's has an positive effect. Below, here's the last batman logo I tried. As many time, the problem begin often with the "frame" who's not sticked to the bed, then after PLA begin to agglomerate and make some damages to the rest of the printing. I also feel there is a big lack of precision who don't allow to make severals time the same print, that's worried me the most...

Thanks again for you responses.

Alex

Re: Stuck in the First Cal. Layer zone

I would suggest you wash the bed with a drop of detergent and water. Rinse and wipe with paper.

It usually works better than chemicals that do not dissolve all dirt. Between the prints you can then use 99.5% isopropanol or similar.

Bear MK3 with Bondtech extruder

Re: Stuck in the First Cal. Layer zone

Another thing to try would be to lower the first layer speed. In Slic3r, its under the Speed section of Print Settings. Mine defaults to 30mm/s and I've had generally better luck lowering it to 20mm/s.

It also seems like it would be worth trying some different filament to see if the problem is unique to the spool you are using (even though its from Prusa which is generally quite good, perhaps there is an issue with the one you received).

Re: Stuck in the First Cal. Layer zone

Any updates as I am having this same problem?????

Re: Stuck in the First Cal. Layer zone

I was thinking the same, I forgot to tell in the previous message, but I also tried to change the PINDA height. I had the feeling that either it's too high or too lo, even if I change it of one click. I had tried to be close to the bed, but during the XYZ cal the nozzle slightly moved the paper so I stop the sequence, move the PINDA again to have this -1095 result ? It seems there's no in between...

Hi Alex,

I don't know if you've seen my post, but I'm having a similar problem in not being able to find the optimal PINDA height (and I've been adjusting by 0.25mm.) When I do get a first layer down (at -1.250mm or more) adhesion seems fine.

In one of your posts, I believe you mentioned using ethanol(?) Isopropanol (a.k.a.Isopropyl) is recommended, and it's been working fine for me (albeit at the wrong height).

Here's to our both solving this problem! 😉

That's "MISTER Old Fart" to you!

Re: Stuck in the First Cal. Layer zone

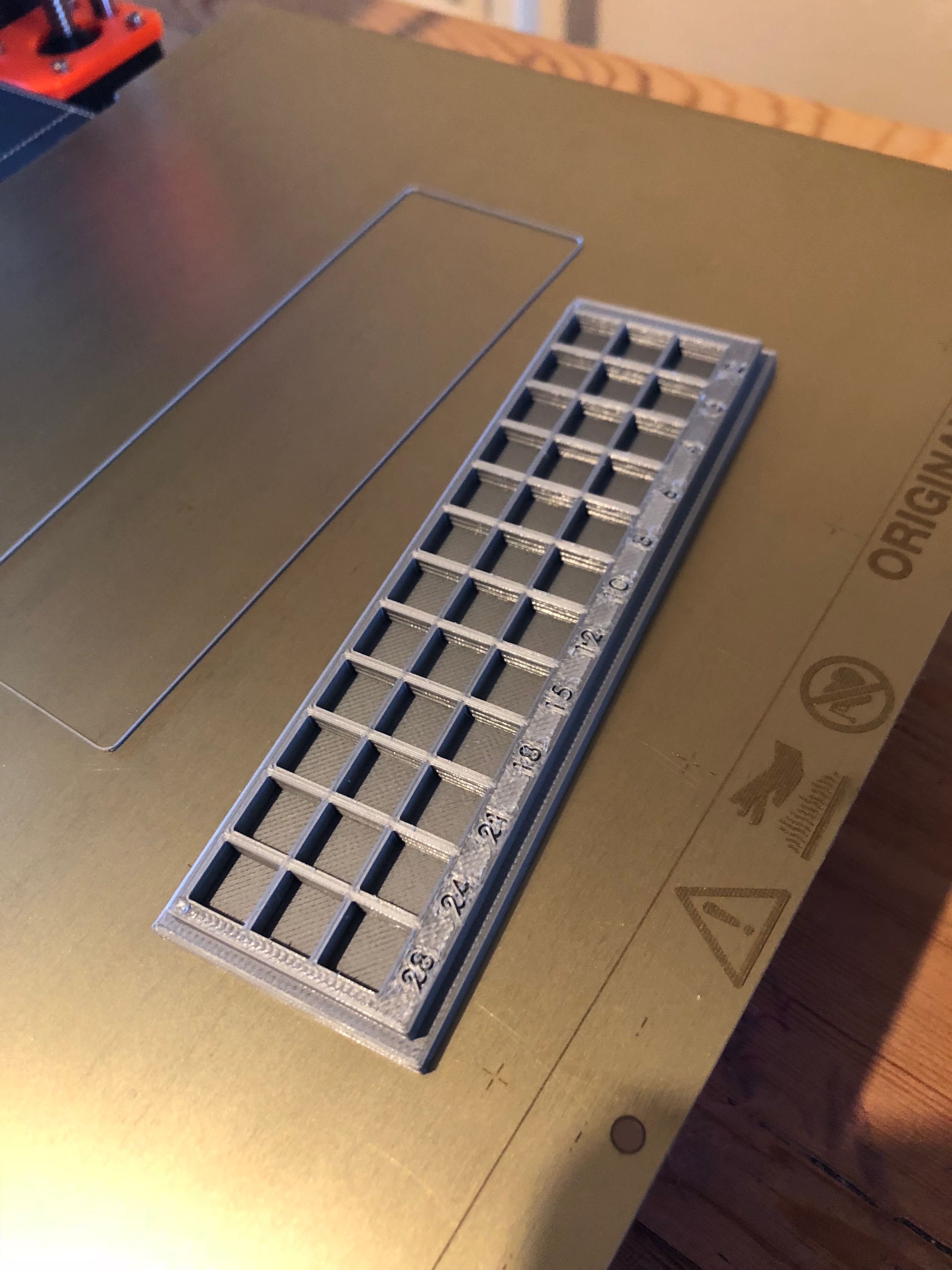

Hi guys, sorry for the black out, but with work and holiday prep I don't have much time to continue tests or write big post. Good to know, I succeed to do a better adjustment of the Pinda. I also raise a bit the PLA temp to 220, and as advice do a better cleaning, with glass spray of the bed. So I succeed to print a Batman logo

and after I tried to print a piece of my own design, which was not perfect but ok :

I still need adjustment but it seems to not be linked to the first layers cal. ?