Small test prints looked ok, complex and larger prints show many issues?

Hello community,

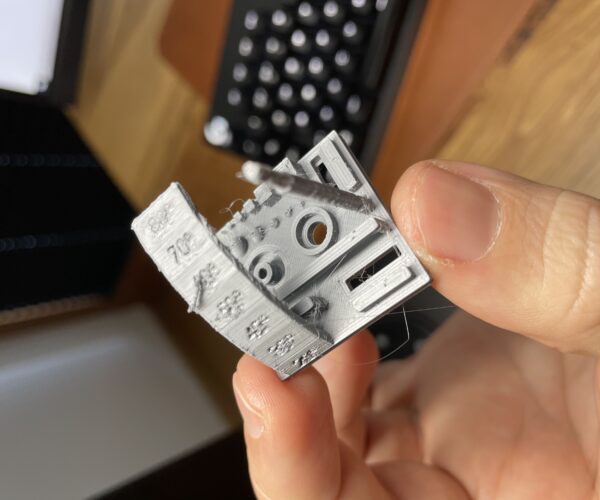

- I have been running though the calibration steps of TeachingTech3D and most seemed fine, but then I started printing larger parts and noticed it’s not all benchys and cubes out there, when I attempted the enclosure parts. Can someone have a look at this and the test prints and give me pointers? The white filament is PETG, the grey all-in-one print was PLA.

RE: Small test prints looked ok, complex and larger prints show many issues?

Actually, could it be the nozzle being clogged already, after 6-8 prints of smaller calibration items?

RE: Small test prints looked ok, complex and larger prints show many issues?

Your first layer appears to be a little too squished. This can force adjacent plastic sideways thus stressing first layer adhesion.

PETG stringing is not too bad, light tweaking of working temperatures might help but light sanding or a brief post-process blast from a heat gun will get rid of most of it.

As a general rule increase size and complexity of your prints slowly over time as you gain experience and refine your tuning/calibration.

Your settings are already better adjusted than many of the beginner problems we see here, you are on your way. Keep at it, practice and experience will accrue from now on; but do feel free to come back as you encounter new issues.

Cheerio,