Recurring Jam in the extruder

Hello

I have a recurring problem of jam in the extruder, and randomly:

-Some Parts Yes, some parts no, without finding "common" reasons, I even rotated the parts for printing (and in most cases this does not happen anymore, but with a less quality)

-This occurs at different heights, from a few millimeters to a few centimeters

-I tried to change the flow (Initial: 95, 100 , 90 ): Same issue

-I tried to add a full cube, wishing to put the flow of filament on parts with less deposits per layer: Same issue

-I tried to make a frequent filament change over the printing time (every 15min on a 3h print): Same issue

-I tried to change slicer (PrusaControl Beta, Slicer, Cura): Same issue

Additional Information:

-When this occurs , the change of filament is carried out correctly as a general rule (see note below for other cases), so in my opinion no nozzle clogged

-In some cases, when removing the filament, that "breaks" at the entrance of the PTFE tube, and it is just the horror: dismantling of the whole head, and often replaced PTFE. In this case, I realized that the filament "force" not bad in PTFE, so much that it folds slightly in PTFE: I put this on the account of the power of the training of the filament.

-I have already changed in 6 months, 3 times the printhead with a hotend of original Prusa, PTFE, and 6 times the nozzle.

I despair, and it's quite frustrating because it's personally the only problem I have with my Prusa MK3 and randomly on short impressions (< 5h), and more frequently on long impressions (> 10h-15:00)

Does anyone have the same problem and find solution?

I am new in printing, and 3D technical English terms are unknown for me, so be lenient with me 🙂

Thank you

Dp

Re: Recurring Jam in the extruder

Good morning Dp,

have you tried reducing your retraction length setting?

sometimes when there are a lot of retractions the filament causes a jam below the PTFE Liner tube. in the heatbreak,

reducing the retraction distance can reduce the chance of this occurring

worst case, try 0mm retraction, you will get some stringing, but it may stop your jamming...

then increase retraction till the stringing stops but stay at maximum 0.8mm or less

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Recurring Jam in the extruder

Hello Joan,

Thank you for your help, and your proposal but unfortunately, this does not seem to have done anything tonight:

-Reduction of the retractation of 0.8, 0.5 then 0.2 : Same result.

-According to the post of this forum and the Prusa firmware GIT I saw that the temperature Extruder stepmotor could spawned a jam. The engine is actually quite hot, barely touchable by hand: I tried to reduce the head temperature to 205 degrees without better results.

-I also tried to reduce the fan speed to 75%: always the same result

I'm starting to lose the little hair I left:-(

Any other ideas?

I'm joining the STL, and my GCODE since Cura.

Thank you again,

Dp.

Re: Recurring Jam in the extruder

Then you should check, if your filament path through the extruder gears is straight. If it is not absolutely straight, friction makes your extruder work harder, therefore heat up more.

Also take a look, if the extruder-gear on the idler side can freely rotate, and of the shaft is securely located on both sides within the plastic frame.

Check your extruder tension. The screw heads on the left side below the hexagonal hole should still be a bit above the plastic. Since your motor is very warm, I'd bet, those are too tight.

[Edited a myriad of typos 😳 ]

Re: Recurring Jam in the extruder

Hello,

Thansk for additionnal idea, i will check that in next 2 days and back to you, I hope with good news 🙂

thanks,

Bertrand.

Re: Recurring Jam in the extruder

Good evening

I was able to do additional tests:

1. Loosen the spring screws

2. Set the training wheel

3. Put the PTFE before the notched drive wheels (it was not in the package for the upgrade B3/R7)

On the other hand, I can't check the voltage on the motor. I had in the idea to reduce the current for the engine to extrude it, but I do not know the basic current firmware...:-(... anyone have any idea?

Here are my latest tests:

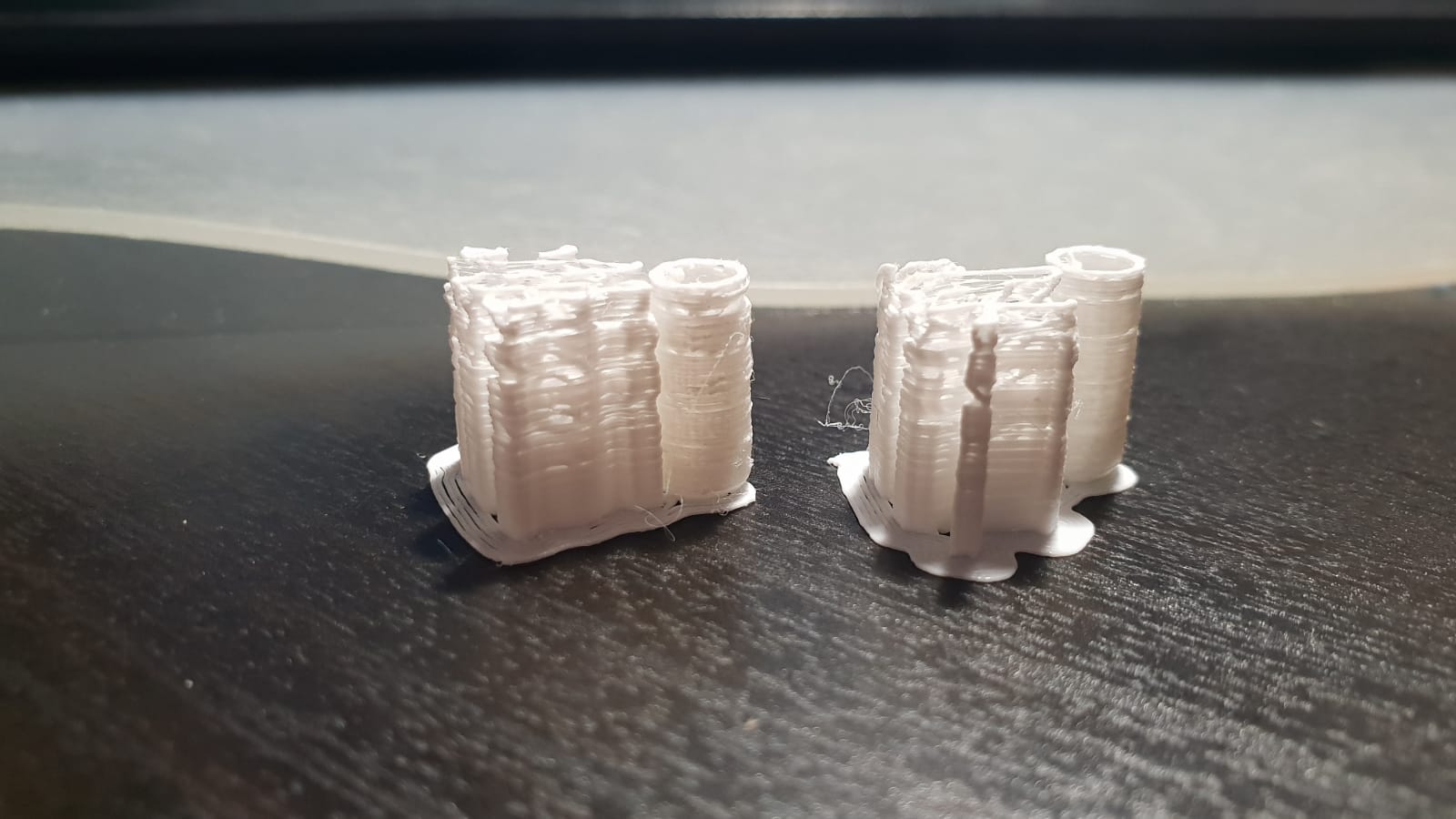

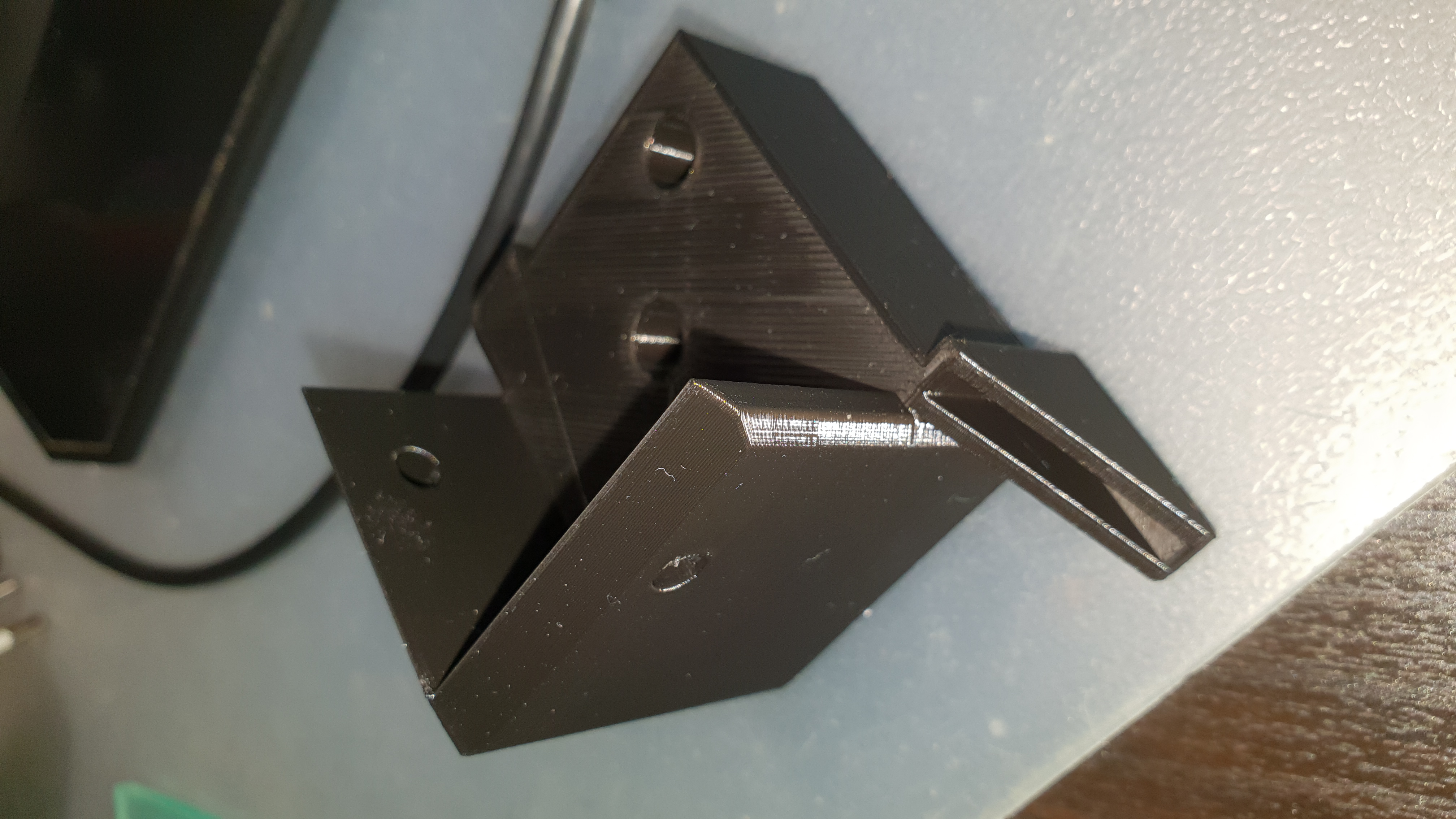

And in same time, I designed some support, and print them: If exeterio seems to be good, during print, the internal have been absolutly an horror…. :

Re: Recurring Jam in the extruder

That’s looking great, are you still suffering from jams after your checks?

Re: Recurring Jam in the extruder

Yes, this is good, but my STL of test (Fake AirPod) are Always in fault 🙁