Really REALLY frustrated

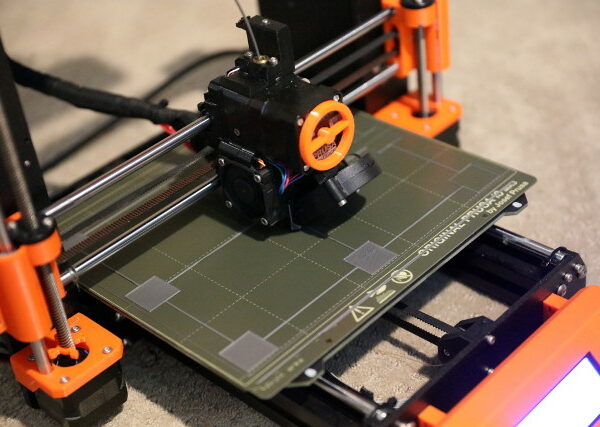

Sigh. Right now, I just seem to be having issue after issue with my MK3s. I have gone through and tightened everything up by try as I might, I can't seem to have it keep a z axis offset. What I mean is that I do 5 or 10 prints and double check everything to find out that my Z offset is right out for my first layer, I tune it back up again and 5 or 10 prints later it seems to be out again.

I am still troubleshooting and just spent 3 hours on the Z axis again.

I have just changed my nozzle again (went from a brass one to a nozzle x and now another nozzle x)

Firmware reset the entire thing and I am really grumpy.

I absolutely hate the pattern that is in the Prusa Firmaware because IMO it runs backwards. If it ran from the front of the machine to the back, I could see each change as did it instead of looking between the nozzle an the bed for the entire thing.

I think I have it dialed in now - at least well enough for it to print something really badly. That's better than watching as previously printed lines or details jump up and attach to the nozzle, making a nice blob while I watch...

Genuinely, I'm just really frustrated and needed somewhere to vent. I had it tuned so I could print out well just a couple of days ago and now today it's saying "Nope. No prints for you."

RE: Really REALLY frustrated

I would suggest using one of those 3x3 test pattern prints which show your Z calibration at all major points on the print bed instead of just one. I use it as a sanity check occasionally. Each square should be smooth and solid.

If you end up having some squares good and others bad, you can do an advanced calibration and tweak front/rear and left/right individually.

RE: Really REALLY frustrated

... What I mean is that I do 5 or 10 prints and double check everything to find out that my Z offset is right out for my first layer, I tune it back up again and 5 or 10 prints later it seems to be out again.

Genuinely, I'm just really frustrated and needed somewhere to vent. I had it tuned so I could print out well just a couple of days ago and now today it's saying "Nope. No prints for you."

The issue is the PINDA is temperature sensitive. Set Live-Z when the printer is cold and you'll get one number. Go back and redo the exact same print just after printing the same thing and layer one is toast. If you try to adjust for this you will drive yourself crazy.

The way around this tail-chasing party is to ensure the PINDA is the same temperature every time you run the bed level. Every print.

You do this in the Printer Startup Gcode. The trade-off is it takes a bit longer for each print because you have to wait for the PINDA temp to stabilize. But, it is well worth the wait.

Here's a segment of my gcode that does this: I've tweaked it to run a bit faster by using 35c as the set point, 37.5 or 40.0 is better -- but can extend the delay to print a long time (printer acts dead during the PINDA heat pause). Try 35c, see if it helps.

Printer Settings - Custom Gcode - Startup Gcode

M115 U3.7.1 ; tell printer latest fw version

G90 ; use absolute coordinates

M83 ; extruder relative mode

; cool down PINDA

M106 S255 ; turn on fan

M104 S0 ; turn off nozzle heat

M140 S0 ; turn off bed heat

M860 S35 ; wait until PINDA is less than 35C

M106 S0 ; turn off fan

; preheat nozzle to a low temp, get plastic mushy before driving into the bed with G28

M140 S[first_layer_bed_temperature] ; set bed temp

M109 R175 ; wait for extruder temp

M190 R[first_layer_bed_temperature] ; set & wait for bed temp

G28 W ; home all without mesh bed level

; soak PINDA to temp then level

G0 X50 Y50 Z1 F3000; this is a good PINDA heating position

M860 S35.0 ; wait until PINDA is >= 35C in winter, 37.5C spring/fall, 40C summer

G80 N7 R5; mesh bed leveling

; heat to extrude temp

G0 X0 Y-3.0 Z10 F3000; this is a good nozzle heating position

M109 R[first_layer_temperature] ; set & wait extruder temp

; purge

G1 Y-3.0 Z0.20 F1000.0 ; go outside print area

G92 E0.0

G1 X1.0 Y-1.0 E0.5 F500.0 ; scribble 1

G1 X1.0 Y-3.0 E0.5 F500.0 ; scribble 1

G1 X2.0 Y-1.0 E0.5 F500.0 ; scribble 2

G1 X2.0 Y-3.0 E0.5 F500.0 ; scribble 2

G1 X3.0 Y-1.0 E0.5 F500.0 ; scribble 3

G1 X3.0 Y-3.0 E0.5 F500.0 ; scribble 3

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.0 F1200.0 ; intro line

G1 X97.0 F2000.0 ; wipe left

G1 X105.0 F3000.0 ; wipe right

G92 E0.0

M221 S{if layer_height<0.075}100{else}95{endif}

; end Printer Start gcode