Prusa logo first layer

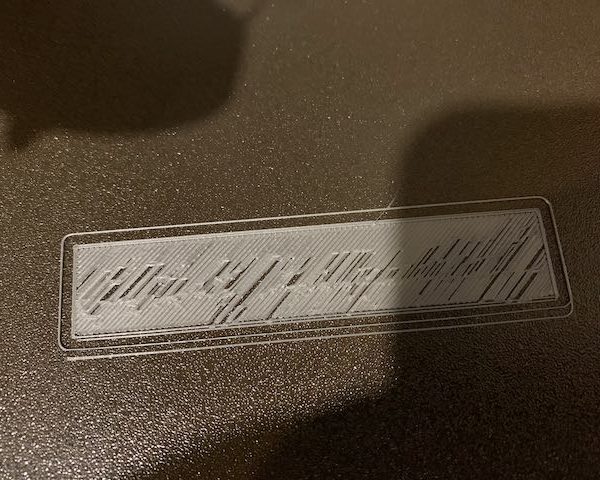

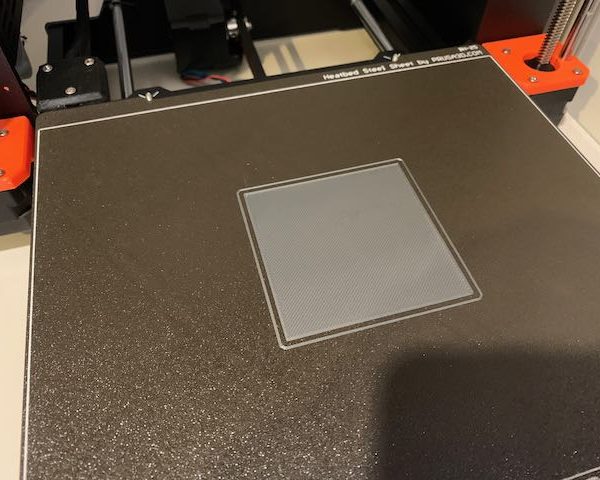

Hi all. Just built a kit. Wizard and calibration all checks out fine but having trouble with a first layer. Attached is an image of Prusa Logo first layer I tried to print. Initially I thought it was Live Z setting and tried increasing it. It helped little with the first layer but wrecked the upper layer print. I am not sure if it is X/Y axis issue (crooked line).

Any help would be greatly appreciated! Thank you

Best Answer by --:

Verify the two belt drive gears are properly installed.

Flat First: Drive gears must be tightened flat-first.

1) Start with both set screws fully loosened so the pulley is free to spin on the motor shaft.

2) Align one set screw dead center with the flat on the motor shaft, slowly tighten the screw until it fully contacts the flat surface.

3) Torque the flat set screw to spec.

4) Now tighten the jam set screw, and torque it to spec.

Once tightened, never touch the flat set screw unless the jam screw is first fully loosened.

Why Flat First? Set screws have flat ends. If you tighten the jam screw first the set screw on the shaft flat doesn't fully contact the shaft, only one small edge of the screw surface is biting. Reversing torques can easily shift the shaft to a position the flat screw no longer contacts the shaft. This lets the jam screw wriggle loose. And after a while, vibration loosens the screws until the gear is free to rotate.

RE: Prusa logo first layer

Verify the two belt drive gears are properly installed.

Flat First: Drive gears must be tightened flat-first.

1) Start with both set screws fully loosened so the pulley is free to spin on the motor shaft.

2) Align one set screw dead center with the flat on the motor shaft, slowly tighten the screw until it fully contacts the flat surface.

3) Torque the flat set screw to spec.

4) Now tighten the jam set screw, and torque it to spec.

Once tightened, never touch the flat set screw unless the jam screw is first fully loosened.

Why Flat First? Set screws have flat ends. If you tighten the jam screw first the set screw on the shaft flat doesn't fully contact the shaft, only one small edge of the screw surface is biting. Reversing torques can easily shift the shaft to a position the flat screw no longer contacts the shaft. This lets the jam screw wriggle loose. And after a while, vibration loosens the screws until the gear is free to rotate.

RE: Prusa logo first layer

Oh, and to eliminate one known issue: disable the filament sensor.