Printing multiple items causes crash

The printer prints single items perfectly. But if there are multiple items printing on the plate, it crashes part way through the print. It seems to be ok with 2 items but more than that and it will crash.

Any ideas how to prevent this happening?

RE: Printing multiple items causes crash

It will crash when one of your items looses adhesion.

Do whatever you need to do to increase adhesion. Cleaning, brims, etc.

RE: Printing multiple items causes crash

Are you talking about printing more items in parallel - i.e. each item has at the moment same height or serially i.e you you start to print next after you finished the previous one?

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Printing multiple items causes crash

@zoltan

It happens when multiple items are printed at one time, so yes - all items at that point in time are the same height.

I am currently printing with Prusa PLA. I wonder whether I need to reduce the temperature a little as there does seem to be a little oozing as it moves from one object to another - could that be knocking the items off the print bed?

RE: Printing multiple items causes crash

Can you pls specify a bit more the crash? If it means that any of your items lose adhesion and starts moving, then concentrate on cleaning the bed/sheet like robert mentioned above. Do you use smooth PEI or textured sheet? Apart of clean sheet surface the first layer calibration is very important - check pls the manual.

If this does not help let us know 😊

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Printing multiple items causes crash

Good morning Dan,

the more items that you try to print on the build plate, the more scope there is for one to come loose and start the demise of the entire print.

factors that cause prints to come loose include :-

1, Build Plate Cleanliness!!!!!! (choose your preferred method, on removable build plates, For PLA, I use dawn / Fairy dish detergent and water, rinsed with hot water and dried immediately with clean paper towels, other people use various preparations that cost more and take longer to clean off afterwards

2, First layer calibration ( https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/ ) again different folks, different strokes!

3, contact surface size and shape.

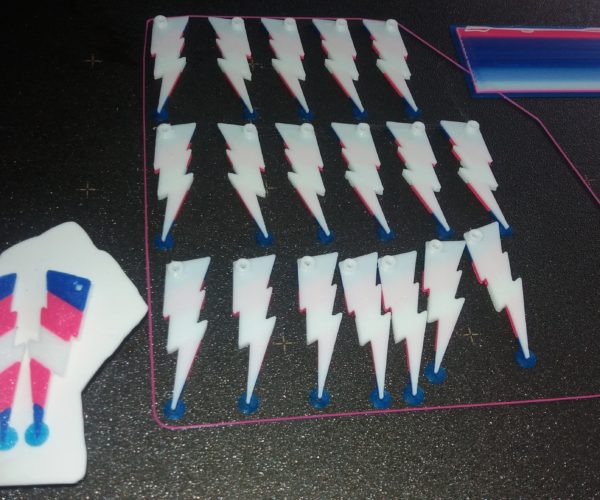

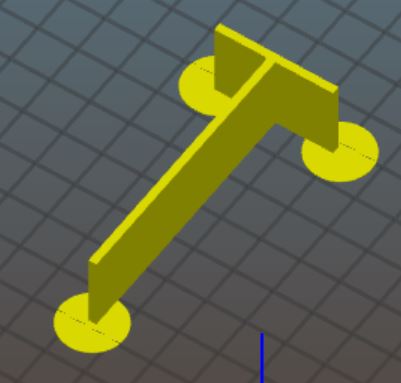

sharp corners tend to lift more easily than round corners, to on these models I used 'Helper discs/ Mouse ears' to stop the sharp points from lifting

4, Bed temperature, raising the bed temperature may help PLA adhere to PEI or textured build plates.

these parts have negligable contact area and sharp ends all I did was to make sure the bed was clean and

raise the bed temperature to 70 Centigrade.

5, Z lift, If the extruder lifts as it moves between objects, there is less likelihood of it hitting the next part and knocking it off the build plate!

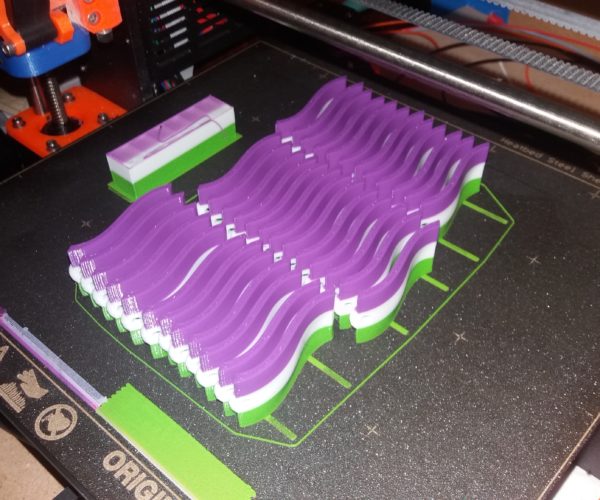

6, contact surface area. adding a 'brim' to a model, can increase the surface contact area significantly, aiding adhesion...

7, model height, Tall thin models can cause adhesion failure because the printing activity at the top, has comparatively massive leverage at the bottom of the model, causing the adhesion to be stressed and fail prematurely.

Adding braces or additional supports can help here

I hope these notes help you resolve your issues

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Printing multiple items causes crash

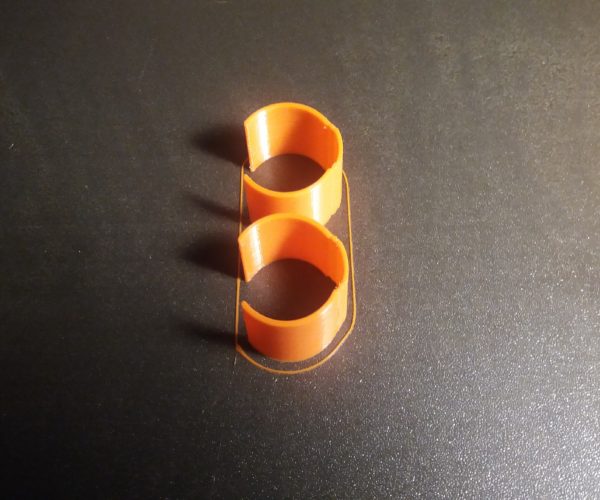

this single shell vase mode print would probably have lifted off the build plate if I hadn't used the Brim at the bottom.

note, a raft can also be used but the interface between a raft and the model often leaves a rough surface.

on these models I have added two small strips to aid adhesion and yet make removal of the strips easier.

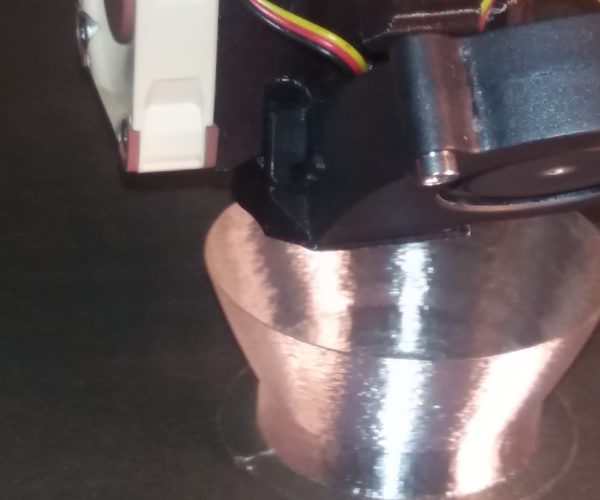

on this model I have added helper discs to prevent the ends lifting...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Printing multiple items causes crash

Something I have never seen mentioned.

With tall thin objects, the top of the object is significantly cooler that the build plate, and sucks heat away from the first layer.

You also tend to get warping from the cooler upper layers that will pull the first layer loose.

A brim can help with both these issues. You have greater surface area, to keep the part "stuck", and the brim helps keep the first layer "hot".

At least, that is my take. I have become a mouse ear fan also.

RE: Printing multiple items causes crash

I just received fully built MK3s. Likewise when printing single items, it is doing fine. I am trying to print 4 items, each with good adhesion to the plate, but on three consecutive prints, one of the 4 (not always the same one) will gum up, and fail. I tried a different filament, tried reslicing it in different ways, with different parts... but same result.

RE: Printing multiple items causes crash

@zargnut

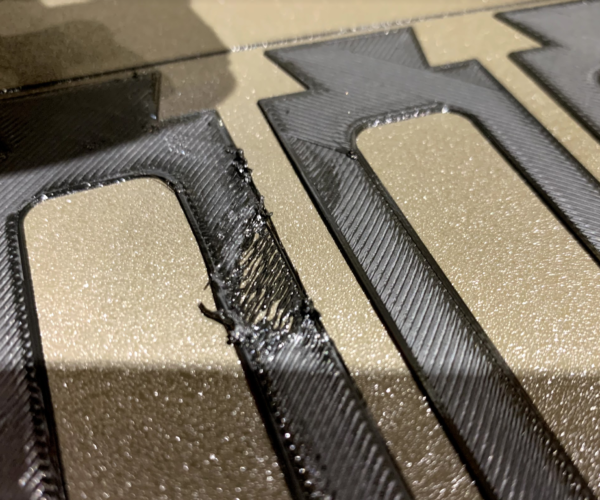

thats what a fingerprint on the build sheet looks like - when the filament hits the oils form a fingerprint they boil and cause loose adhesion

clean the build sheet with dish detergent ( dawn/fairy) and clean paper towels ( not a used dish towel or sponge)

RE: Printing multiple items causes crash

Ahh...

I was cleaning with ISO alcohol 99%. Do I need to perform two step cleaning? or should the alcohol usually be adequate? This is on the powdercoat plate.

RE: Printing multiple items causes crash

Soap and water are a solo act (we have to love English: is/are/they/it): do not follow with alcohol or you risk adding contaminates. Keep in mind the textured sheet has a warning it doesn't like water (rusts); so make sure it is baked dry after a wash by leaving it on the printer for 30 minutes at 80c.