Print not adhering to build plate

I'm a new user, and was thrilled when I received my assembled i3 printer, to print the Prusa logo and Batman print - with absolutely no issues. However, when I tried printing a g-code that I had spliced, something went wrong, and I stopped the print. When I tried to restart it, the LCD display lost its mind, and showed only gibberish. I pressed the reset button, and the display came back. Thinking I had lost factory calibration, I went to the calibrate wizard to re-do the calibrations. After this, I had nothing but trouble! The first layer calibration was nothing like the handbook shows - I had no right angles at the turns. Watching the nozzle I saw that it was too high, and by the time it laid the filament down, the extruder had already changed direction. I tried the printing the Prusa test print and it was a horrible mess. It moved off the bedplate right away, and the filament was all over the place. The z axis was at zero, so I started lowering it, going to negative numbers. To make a long story short, I think I was headed in the right direction, with the live adjust Z set at about -1. The first level print finally started to look like the picture in the handbook. So, thinking I had the nozzle height correct, I started printing again. However, I had no adhesion to the plate. No sooner had the print started, than it moved off the plate (no adhesion). I tried changing the bedplate temperature, to see if it would help there the print - no good. I changed changing the live Z adjust, more positive. No good. Finally after a bunch of combinations, I was able to make a print by: having live adjust Z at -1.0, reducing print speed to 80% and increasing bedplate temperature to 65 C. Even then, although i was able to finish the print, the build warped slightly at one end. Did I mess the factory calibration up by hitting reset? Which of the changes that I made resulted in me being able to make the build? Can anyone advise if I am on the right track?the right Hoping for some help!

RE: Print not adhering to build plate

There is generally no need to use the factory reset. It sounds like when you did, your z-offset got reset to 0. If you don't like what is happening during a print, you can pause or stop the print from the LCD screen menu at any time.

It sounds like you need to work more on getting your z-offset optimized. Until you do, slowing the print or changing the temperature will not compensate for a nozzle that is too high.

Many newbies think if the print gets knocked off, the nozzle it too low, but often the nozzle is actually too high and the print gets knocked off because of poor adhesion. Another thing that can cause adhesion issues is fingerprints on the sheet. IPA alone is not enough, you need to clean the sheet with dishwashing detergent and plenty of hot water.

I suggest you run a first layer calibration and post a picture of your results so that folks on the forum can help you get the best setting. It can also be helpful for you to post a picture of the BOTTOM of a failed print which will also show how your z-offset is working.

Mk3S+,SL1S

RE: Print not adhering to build plate

Yup. Your Z offset is too high. Go lower.

--------------------

Chuck H

3D Printer Review Blog

RE:

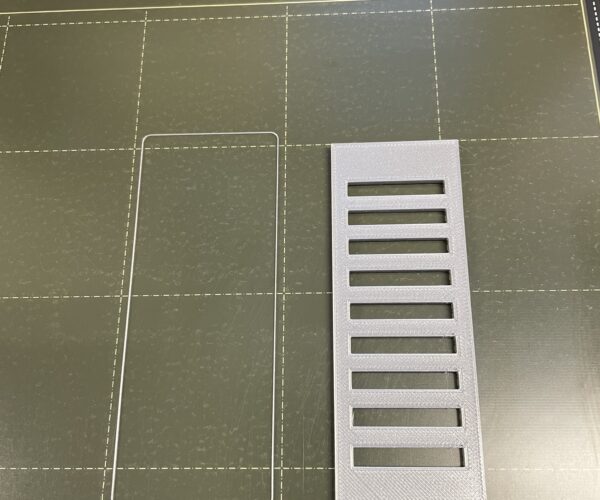

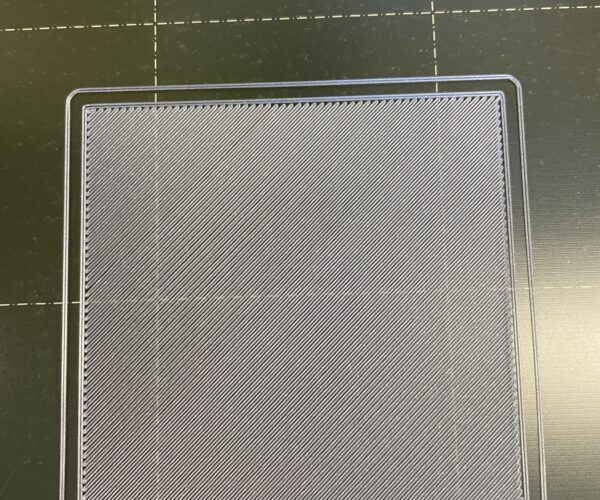

Thanks so much for the help. I certainly will go back and lower my Z live adjust. As per one of your points, I will attach a photo of underside of 2 of the failed builds. (Will do another print soon. My printer is in my garage, and my son left the door open, and it's -30C outside right now (sigh!)! Need to allow time for the garage to heat up again!)

RE: Print not adhering to build plate

Thanks Chuck. On it - will post results soon.

RE: Print not adhering to build plate

Well, I am very happy to say - all is well. Thank you so much everybody for the advice. To make a long story short, I stopped using my 70% Isopropyl alcohol, and started using hot water and Dawn! I also change my Z - went to -1.35. I also looked at another forum post, where someone had posted a 75mm x 75mm test square. Using the new parameters, I printed it, and it looked dandy! I then went to print the Prusa logo. Again, it looked dandy. Then i tried a print that I designed in Tinkercad, and sliced with Prusaslicer. (I wanted to make a ventilated spacer for some electronic equipment. Being afraid to print it as a complete model (afraid of my adherence issues!) I decided to print it in 4 sections, and glue it together - yeh, I was chicken!). But, they also turned out just dandy! I’m just printing the 3rd of the 4 sections. I will include some photos below. Once again, I would like to thank everyone for their help! (One last question - how do I close this topic!!)

RE: Print not adhering to build plate

I’ll be brave and do it! I have this awful image of the nozzle gouging the bed plate! (Yikes!)

RE: Print not adhering to build plate

At this stage, you go down in small increments. If you are getting too low, it will be obvious as you would be getting hardly anything to extrude.

Mk3S+,SL1S

RE: Print not adhering to build plate

You bet. I will be very careful. I’m really appreciative of your advice. It’s really good for a newbie to have the support of the community of experienced users. Although I was able to successfully print my little project, there are still problems with the other ones I have built. I think I need to continue to hunker down and try to understand, Prusaslicer especially. However, it’s coming! This latest advice is great - it’s a great heads up for when I get too low - I will heed it. Thank you again.